TFT-LCD (thin film transistor liquid crystal display) pixel electrode layer structure, preparation method and mask plate thereof

A pixel electrode layer and pixel electrode technology, applied in the direction of circuits, electrical components, optomechanical equipment, etc., can solve problems such as abnormal display, lower product yield, lower panel display quality, etc., to reduce the difference in developer concentration, Avoid the effect of twill mura

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

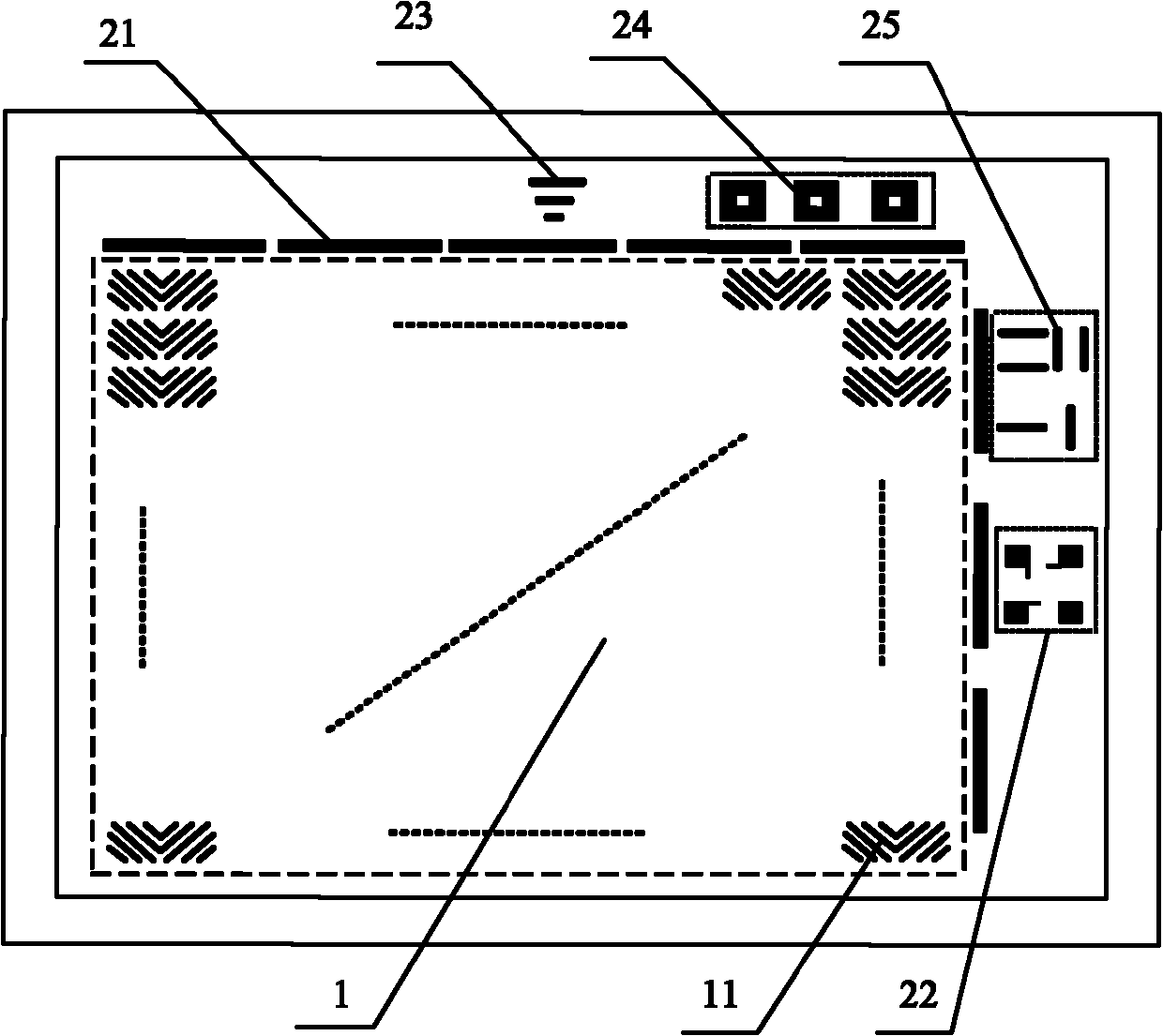

[0038] Since in the development process for preparing the pixel electrode layer, in the non-display area, the area of the pattern in the peripheral area is relatively small, therefore, taking the positive photoresist as an example, the area of the photoresist that needs to be reserved in the non-display area is also small. Most of the photoresist reacts with the developer, and consumes more developer, while in the display area, the remaining photoresist area is larger, and the developer is less consumed. Therefore, the periphery of the panel (non-display area) and the panel The concentration of developer in the center (display area) is different, resulting in uneven distribution of developer concentration on the entire panel, and the concentration of developer around the panel is much smaller than that in the center of the panel, which causes the concentration of developer in the center of the panel to flow to the panel. Peripheral diffusion, resulting in DI CD being affect...

Embodiment 2

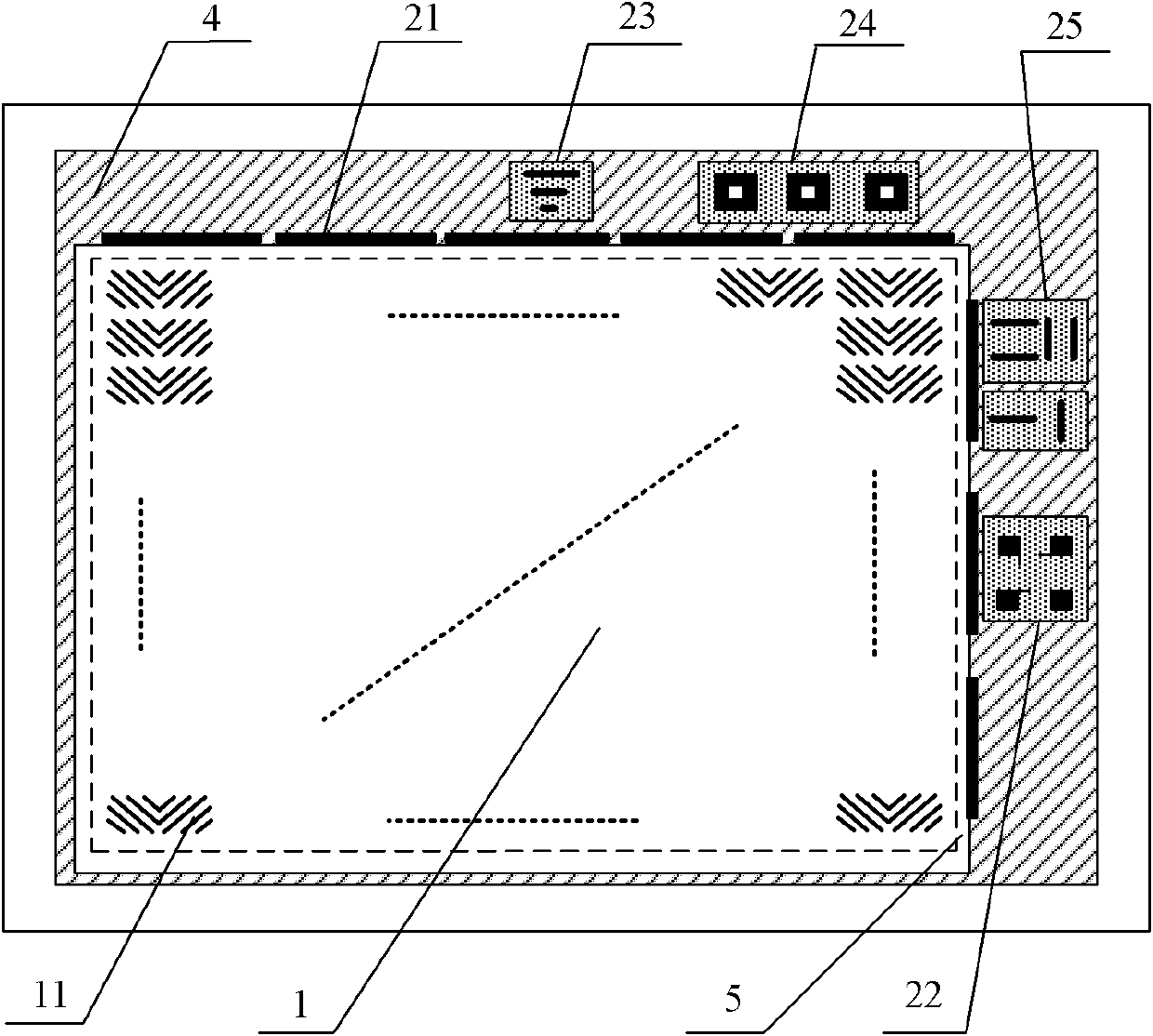

[0045] On the basis of embodiment one, further, as image 3 As shown, the peripheral filling graphics 4 and the graphics included in the peripheral area graphics are not connected to each other and are independent of each other. In order to avoid the mutual interference between the peripheral filling pattern and the graphics contained in the surrounding area pattern, and affect the function of the surrounding area pattern, the peripheral filling pattern and the peripheral driving circuit part, the pattern used for process detection, and the pattern used for mask plate alignment are mutually incompatible. Connection, so that the original surrounding area graphics and surrounding filling graphics are independent of each other.

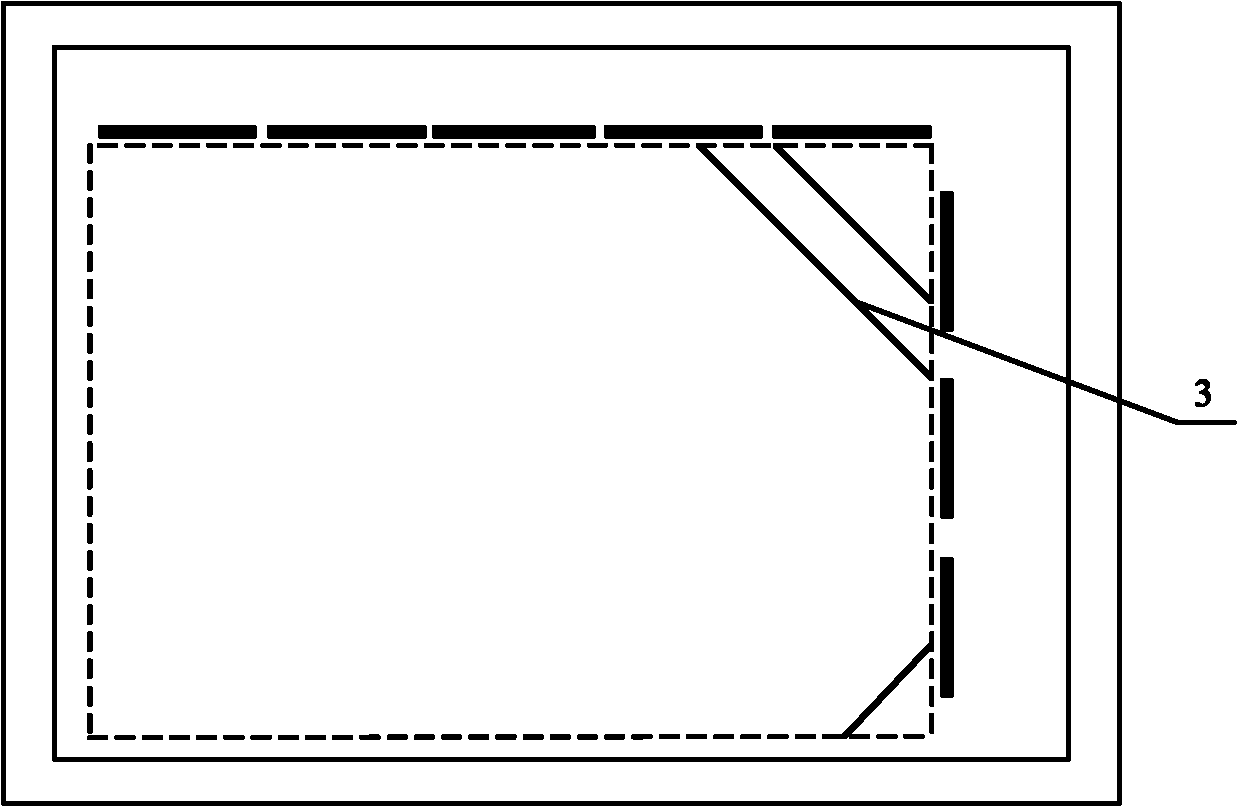

[0046] Furthermore, since it is difficult to ensure that the proportion of photoresist remaining in the display area and the non-display area is exactly the same after exposure using the mask plate provided in this embodiment, the filling pattern 4 on th...

Embodiment 3

[0049] Increase the area of the graphics that need to be reserved in the peripheral area, that is, set the graphics of the peripheral filling graphics, so that the area of the photoresist that needs to be reserved is more appropriate, so that the concentration of the developer in the peripheral area is the same as that in the display area during the development process. Since the area of the peripheral area pattern is small, the influence of the pattern difference is also small. Therefore, on the basis of the above embodiment, further, the pattern texture of the peripheral filling pattern can be set to be the same as that of the pixel electrode pattern. In this way, to the greatest extent, the concentration of the developer in the peripheral area is the same as the concentration of the developer in the display area during the development process.

[0050] Since the developer concentration in the peripheral area and the display area cannot be guaranteed to be exactly the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com