Signal processing method and measuring device for high-voltage frequency converter

A high-voltage frequency converter, voltage signal technology, applied in measurement devices, measurement of electrical variables, measurement using digital measurement technology, etc., can solve the problems of large volume, large error, inaccurate measurement, etc. The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

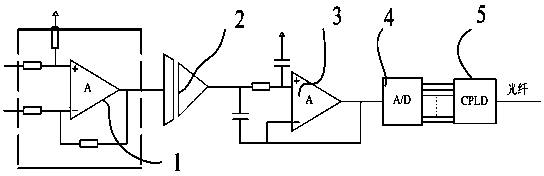

[0028] attached figure 1 A schematic diagram of the present invention is given, and it can be seen from the accompanying drawings that the present invention relates to a voltage signal processing method of a high-voltage frequency converter. The two ends of the terminal and the output adopt the resistor divider to collect the voltage signal respectively, and send the collected voltage signal to an input and output voltage detection device, and carry out digital processing and conversion processing after differential amplification, isolation and filtering of the conditioning circuit. Signal conditioning, and then send the digital processing and conversion results after signal conditioning to the logic processor for calculation and control; and the signal after the logic processor communicates with the main control board of the high-voltage frequency conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com