Feed gas processing device for natural gas

A processing device and raw material gas technology, applied in lighting and heating equipment, liquefaction, solidification, etc., can solve the problems of high cost, large area occupied by the device, and no integrated utilization, etc., to achieve high operating flexibility, high utilization rate, and good The effect of economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

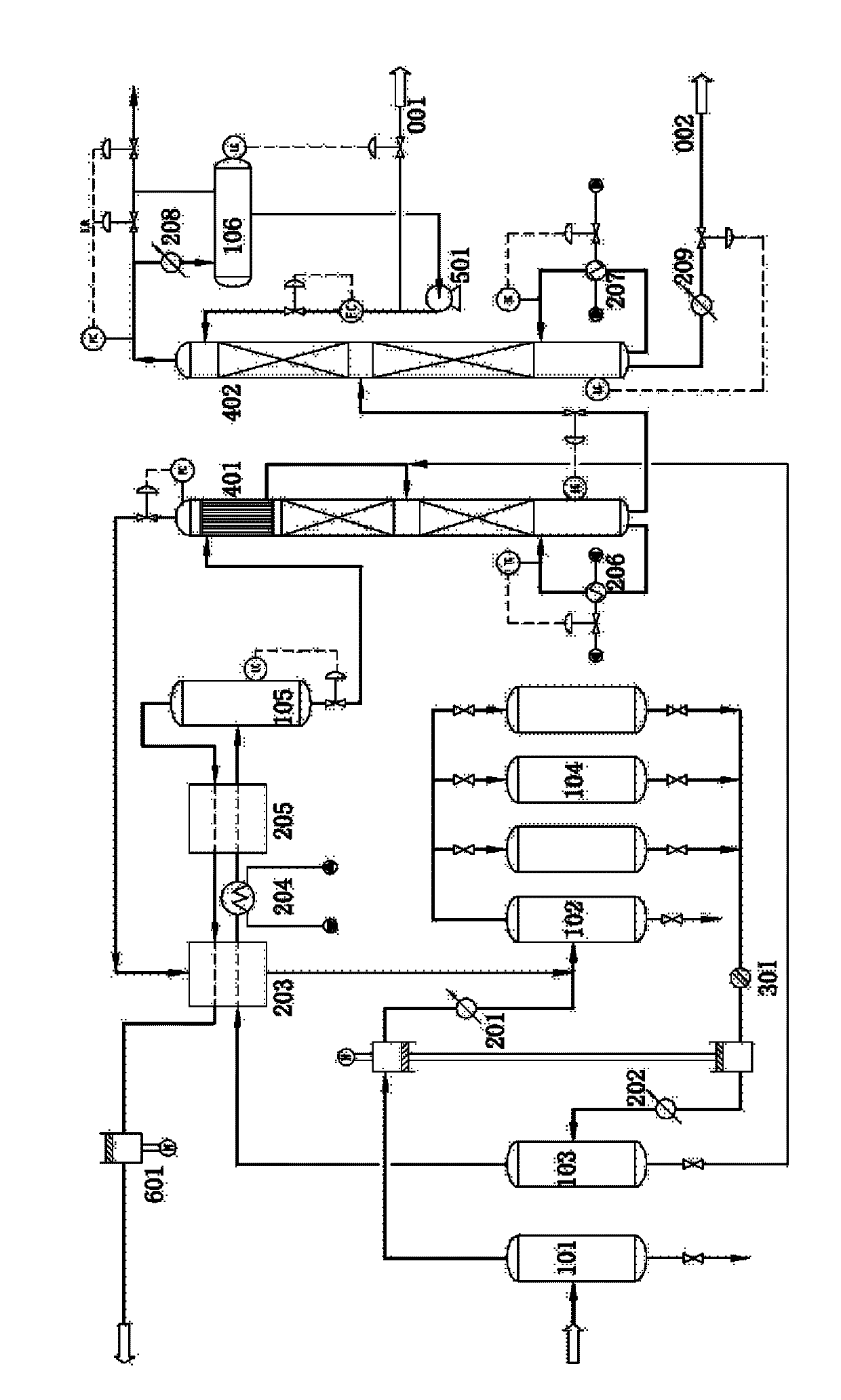

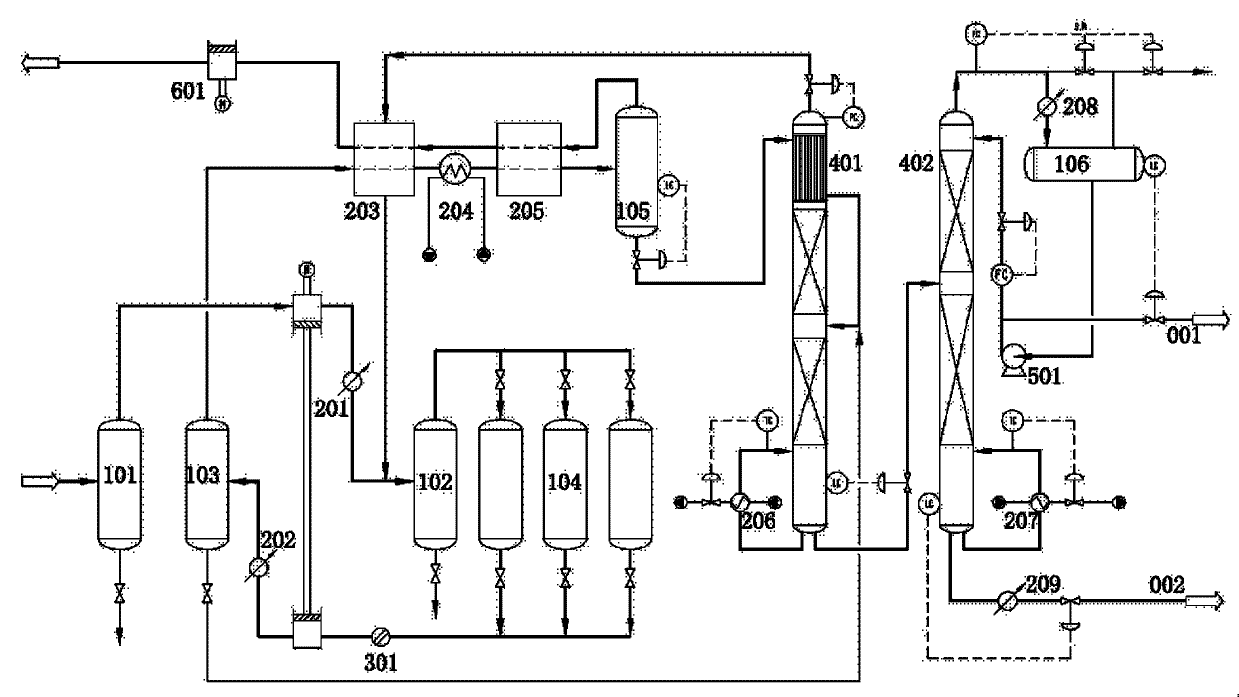

[0030] Generally speaking, the natural gas raw material gas processing device of the present invention is composed of raw material pretreatment, compression, refrigeration, product fractionation, and dry gas compression. The general device components are different according to the scale and raw material composition. deH 2 S (optional), deCO 2 (optional), dehydration and drying (required); the external cooling process of ammonia refrigeration or propane refrigeration is used for refrigeration; the fractionation process of deethanization + debutanization is used for product fractionation.

[0031] The present invention will be further described below through specific embodiments and in conjunction with the accompanying drawings.

[0032] Such as figure 1 As shown, the natural gas raw material gas processing device includes a sequentially connected raw material gas pre-separator 101, a compression device (arranged with a sequentially connected compressor intercooler 201, a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com