Wire rope rolling process mold

A technology for processing dies and steel wire ropes, applied in the field of steel wire rope rolling processing dies, which can solve the problems of easy wire breakage, low production efficiency, and short service life of steel wire ropes, so as to eliminate part of the stress, improve the wear resistance and prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

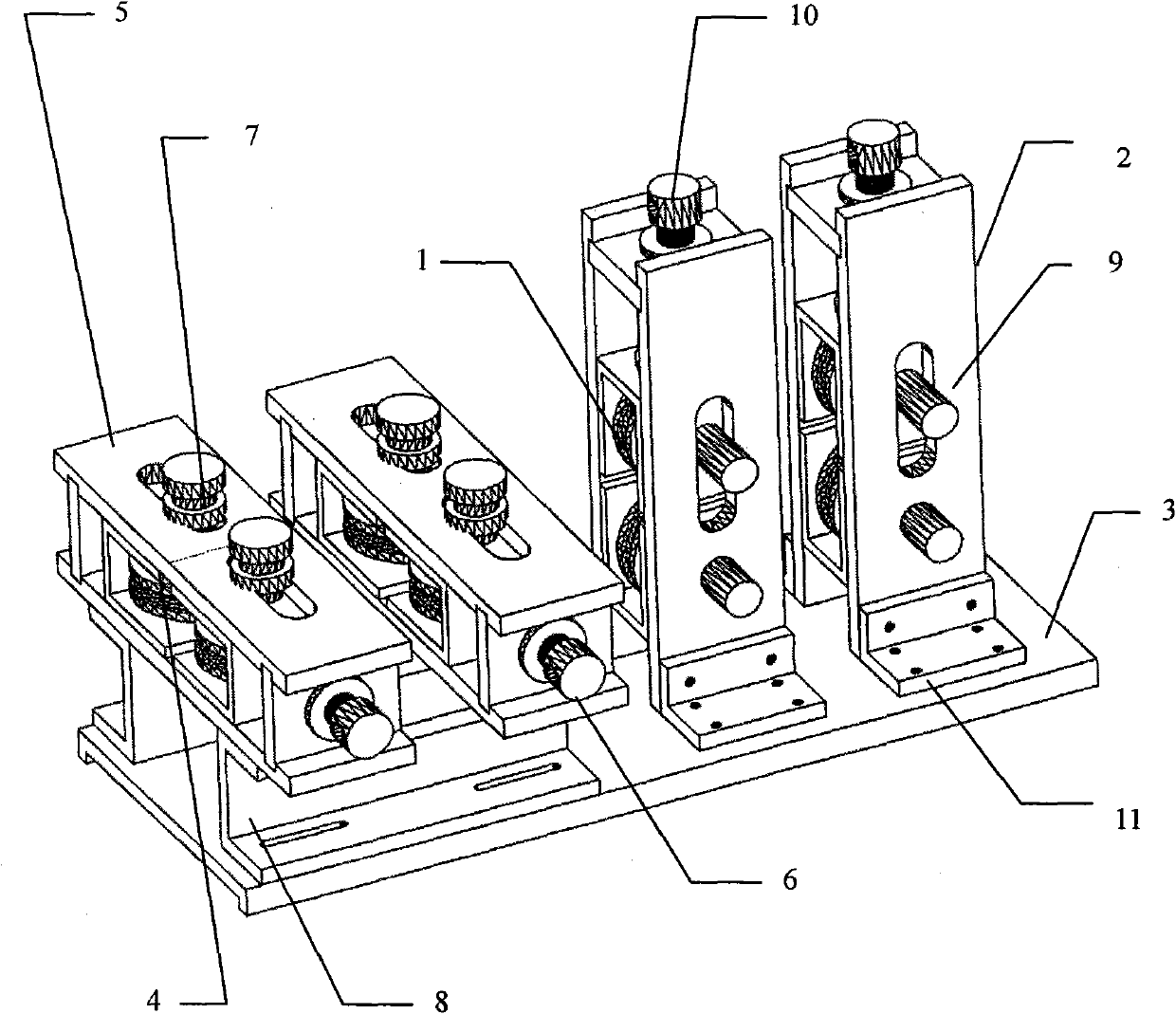

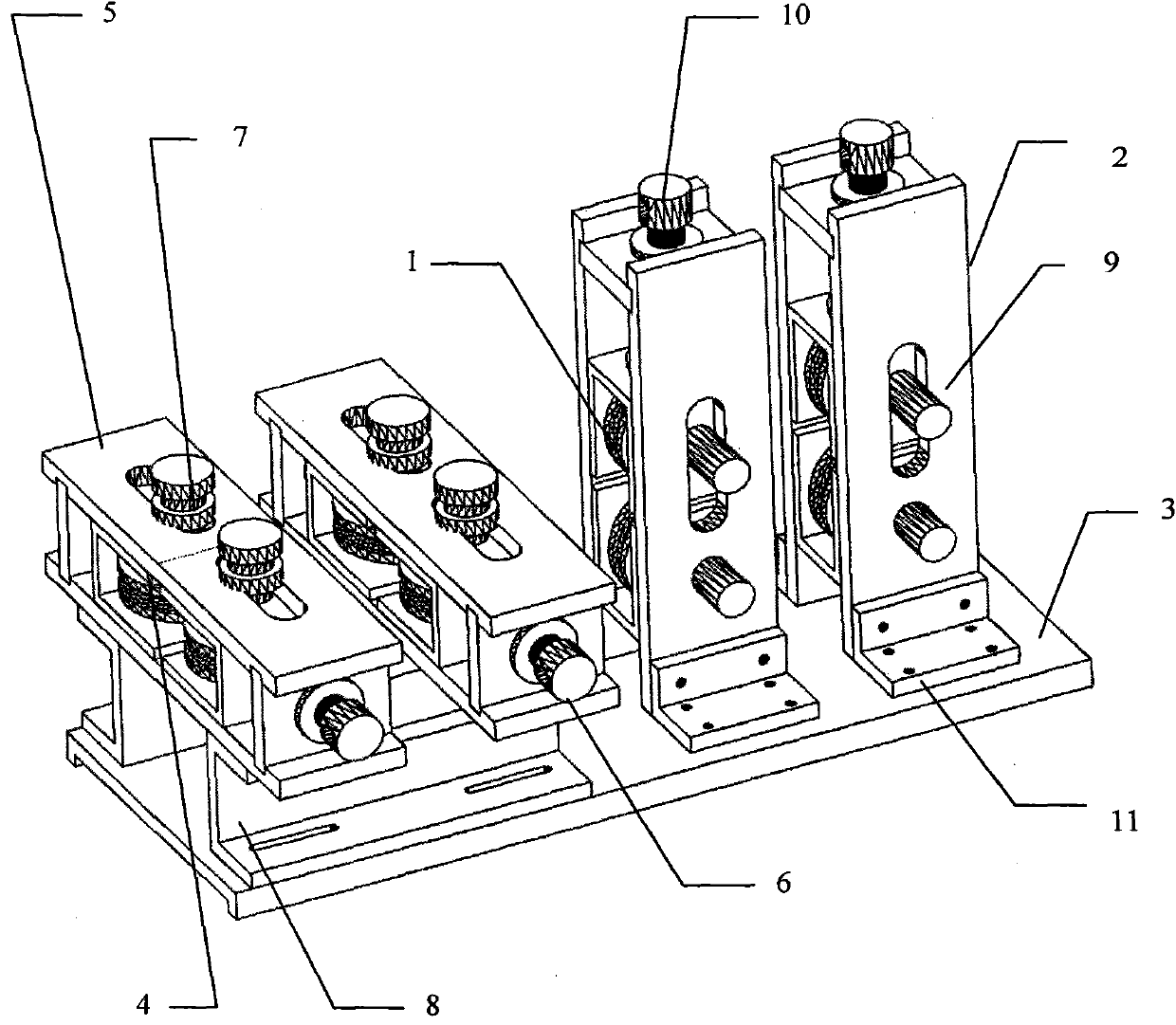

[0009] With reference to accompanying drawing, short spacer 11 of the present invention, long spacer 8 are fixed on the base 3. The horizontal pulley support 5 and the longitudinal pulley support 2 are respectively fixed on the base 3 by the long spacer 8 and the short spacer 11. Two longitudinal pulley shafts 9 are contained on the longitudinal pulley support 2, and longitudinal pulley 1 is adorned on the longitudinal pulley shaft 9, and the longitudinal pulley adjustment screw rod and the longitudinal pulley adjustment nut 10 of the adjustable longitudinal pulley are adorned on the longitudinal pulley support top. Two transverse pulley axles 7 are contained on the transverse pulley support 5, and transverse pulley 4 is contained on the transverse pulley axle, and the transverse pulley adjustment screw rod and the transverse pulley adjustment nut 6 of the adjustable transverse pulley are adorned on the transverse pulley support side.

[0010] When using the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com