Membrane sticking electroplating process for lead frame and special device thereof

A lead frame and electroplating process technology, which is applied to the electroplating process of the lead frame base material strip and its special device field, can solve the problems of unclear outline of electroplating area, side leakage of electroplating, low efficiency of electroplating process, etc., so as to shorten the electroplating time, Improved firmness and clear outline of plated areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

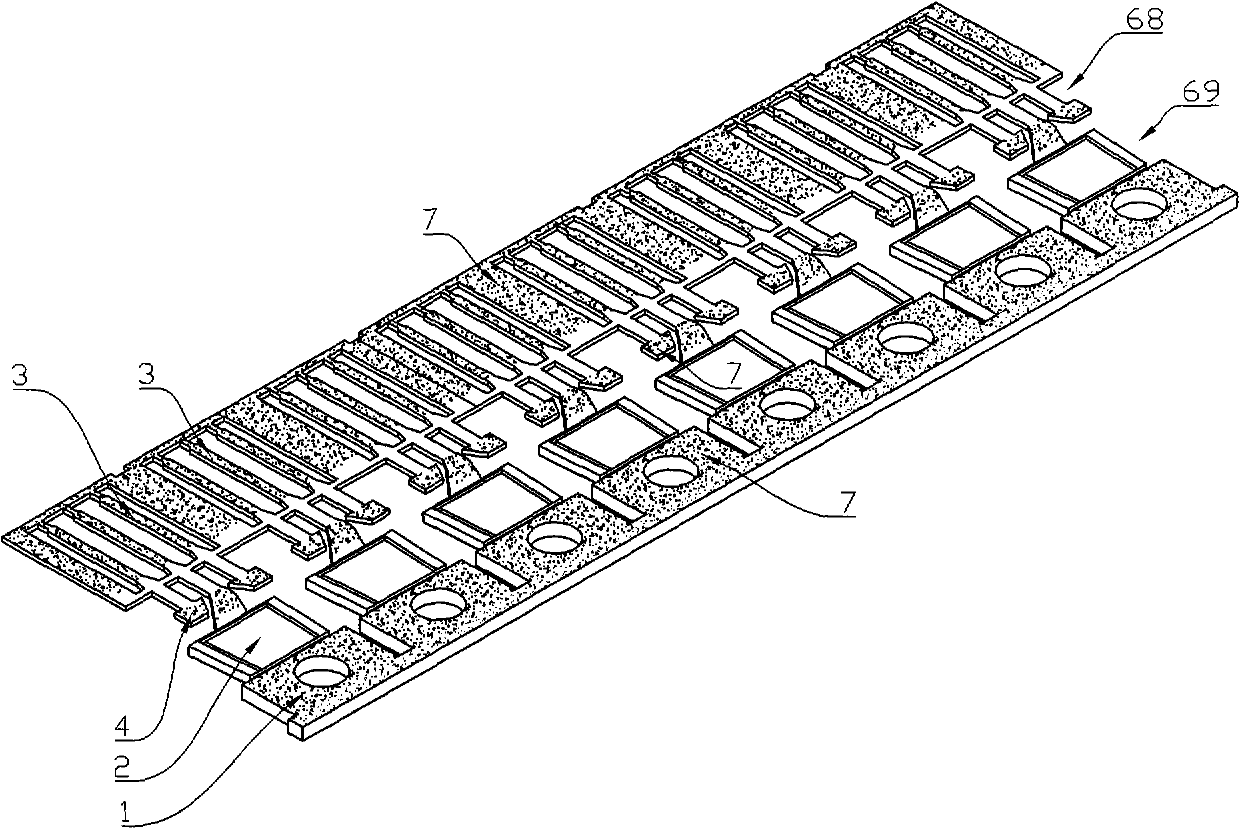

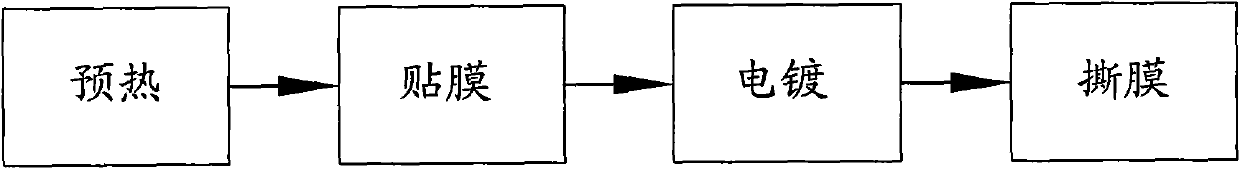

[0028] The present invention produces as figure 1 lead frame products shown as examples, such as figure 2 As shown, the lead frame film-attaching electroplating process of the present invention includes the processes of preheating, film-attaching, electroplating and film tearing to the advancing lead frame base material band 8; Washing, rinsing and drying steps, this preheating process adopts existing known technology and equipment.

[0029] Described film sticking process comprises the following steps:

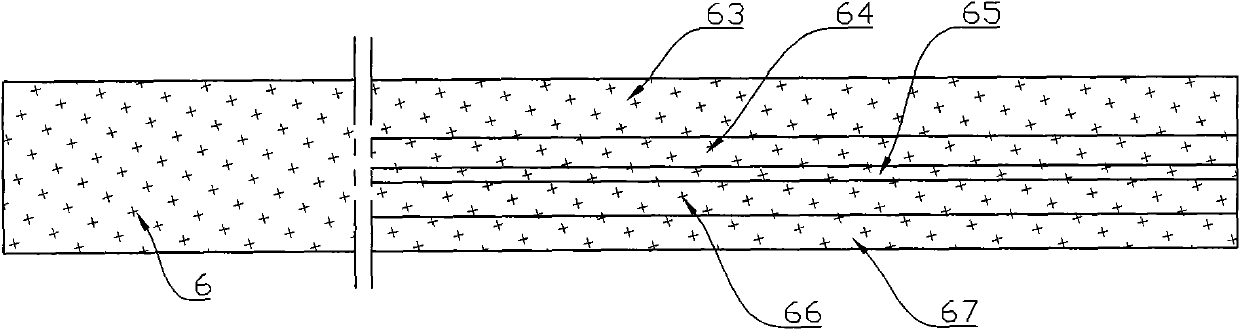

[0030] ① Cutting: such as image 3 with Image 6 As shown, select the adhesive film tape 6 equal to the width of the lead frame base material tape 8, according to the bare surface 68 of the lead frame finished product, the width of the bare surface 69 and the distance relative to the two sides, by multiple blades 242 cut to form a plurality of pellicles 63, pellicle 64, pellicle 65, pellicle 66, and pellicle 67 of corresponding width; The patent No. ZL200410071628.7 aut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com