Aluminum alloy plate and producing method thereof

A technology of aluminum alloy plate and manufacturing method, applied in the direction of final product manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of low thermal expansion coefficient, insufficient flexibility, easy cracking of glass substrates, etc., and achieve high continuous Productivity, elimination of defects in manufacturing efficiency, and excellent high-temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

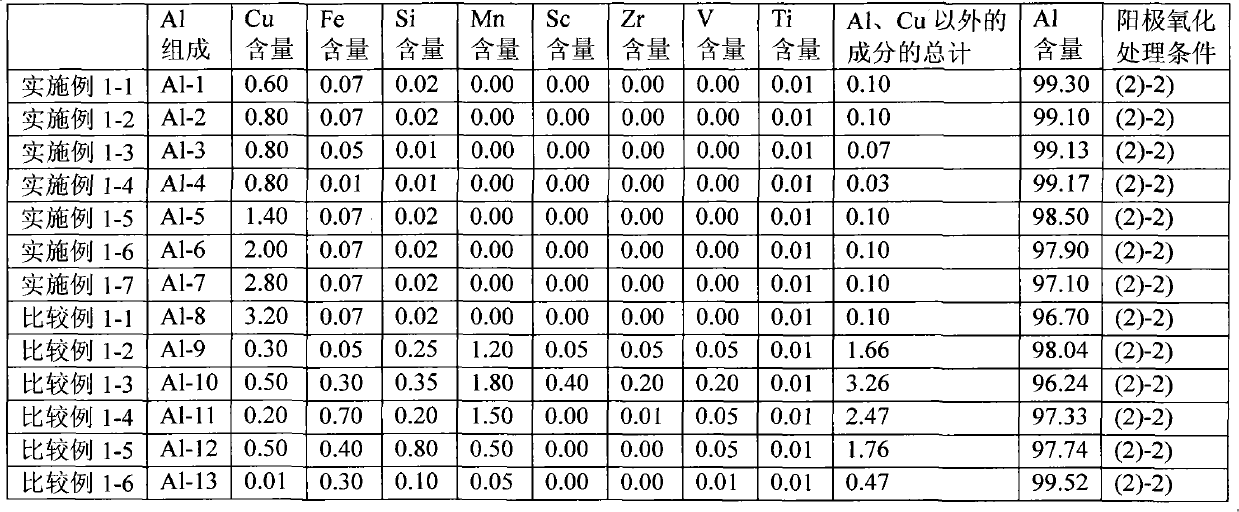

[0155] Hereinafter, although an Example and a comparative example demonstrate this invention, this invention is not limited to these specific examples.

[0156] (Manufacturing example of aluminum alloy plate)

[0157] Aluminum ingots with an aluminum purity of 99.9, 99.96, and 99.93% by mass were prepared, and the following treatments were sequentially performed using aluminum rolled sheets composed of aluminum alloy components shown in Table 1 in which Cu was added to adjust the copper concentration. Al-3 used an ingot with an aluminum purity of 99.93%, and Al-4 used an ingot with an aluminum purity of 99.96%. Al-1, 2, 5, 6, 7, and 8 use aluminum ingots with an aluminum purity of 99.99%. Al-9 and 10 reproduce the composition described in Patent Document 1. Al-11, 12, and 13 reproduce the composition of JIS3004 material, 6015 material, and 1050 material respectively. Al-1-7 are used in the examples of the present invention, and Al-8-13 are used in comparative examples.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com