Inlet guide plate with guide wheel for strip steel rolling, coiling and finishing equipment

A guide wheel and strip steel technology, which is applied in coiling and finishing, and strip steel rolling, can solve the problems of poor coil shape in the next process, difficult coiling, and scrap steel coiling, etc., to improve edge quality , Improve the effect of introduction and service life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

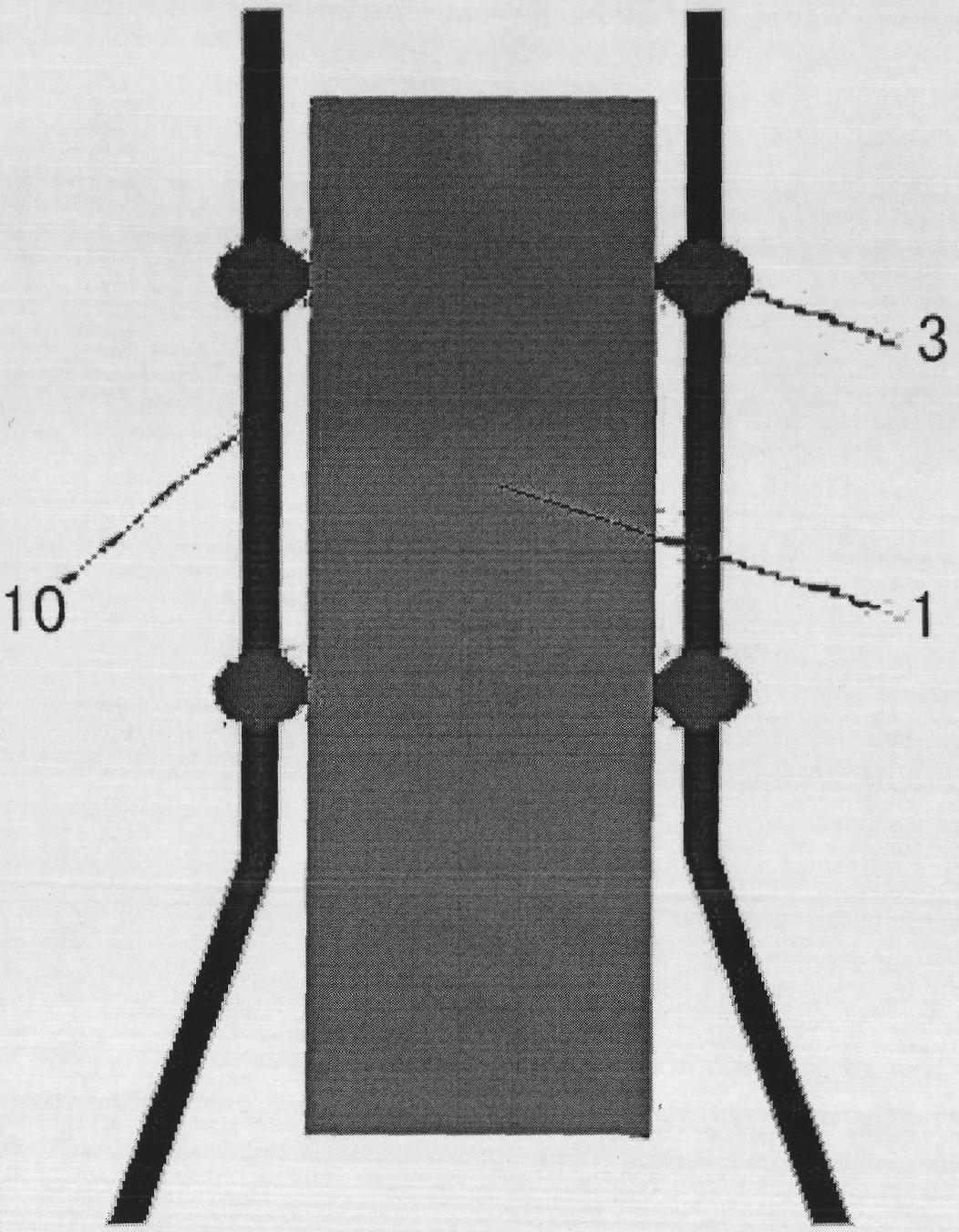

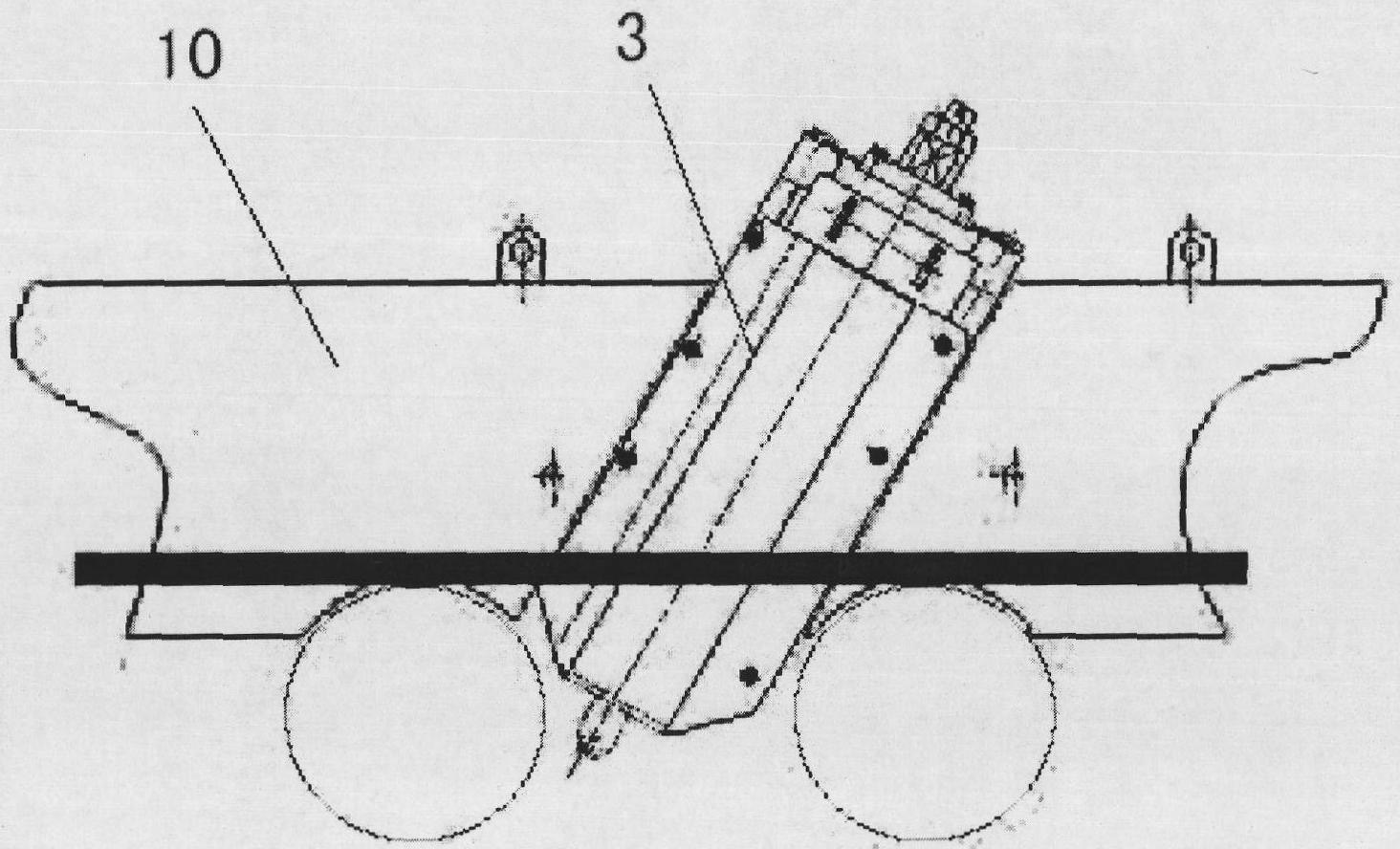

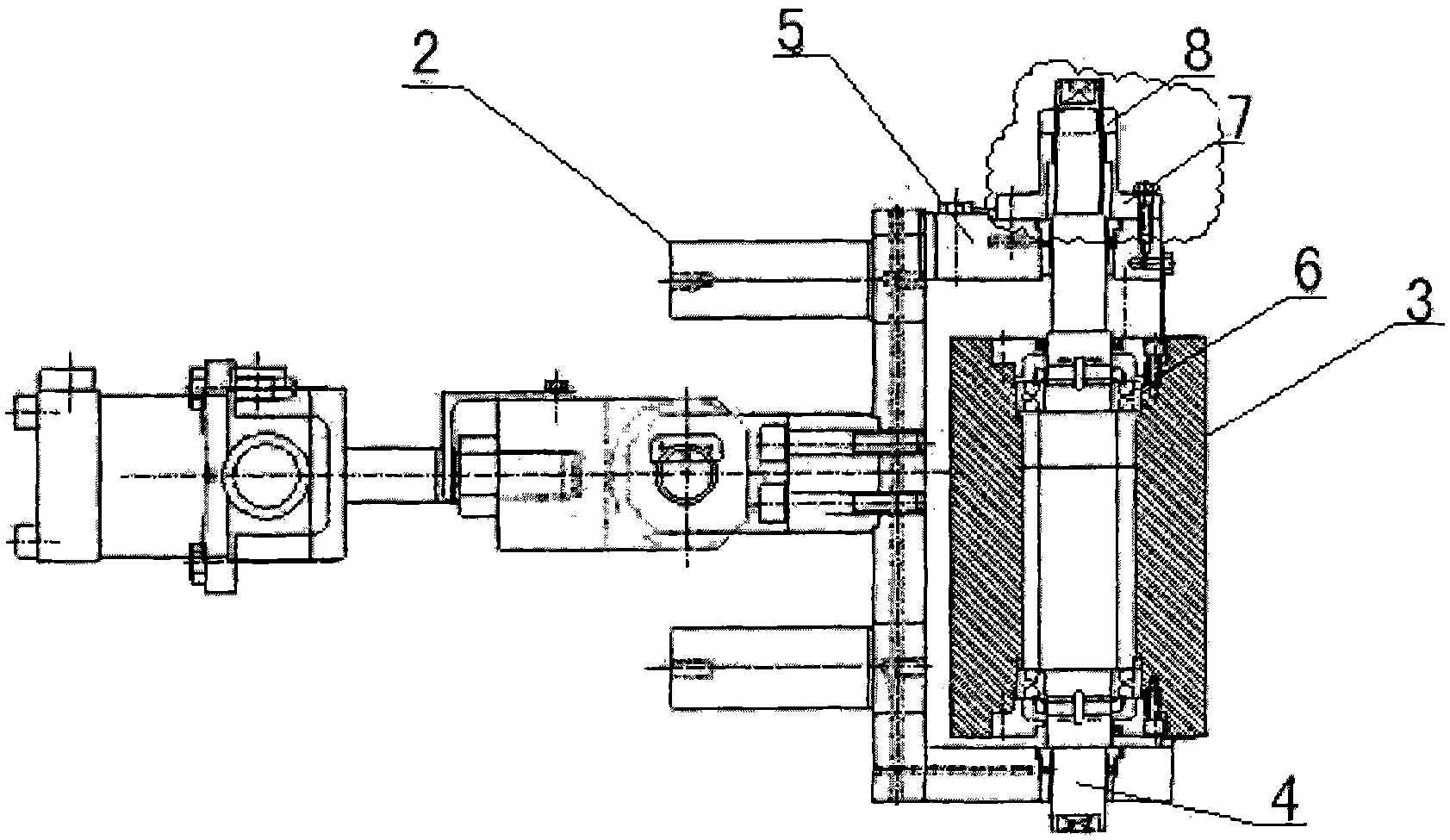

[0031] An entrance guide plate with guide wheels for strip steel rolling, coiling and finishing equipment, comprising guiding strip steel 1 running, guide plates 10 arranged on both sides of the strip steel 1 and guide wheels 3 arranged on the guide plate. The guide wheel is arranged obliquely relative to the guide plate, that is, the direction of the circumferential speed of the guide wheel and the advancing direction of the steel strip 1 have an included angle α of 0-30 degrees. Reach not only preventing strip steel 1 from warping but also avoid overcorrecting and causing buckle.

[0032] Due to the inclined arrangement of the guide wheel, its downward sub-velocity (Vy) can suppress the strip steel 1, so that the strip steel 1 can be transported stably and the head is tilted, and at the same time, it has a certain grinding effect on the edge of the strip steel 1.

[0033] In this embodiment, the height of the guide wheel body can be adjusted to change the contact position be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com