Spraying method for preventing steel plate hot mark machine spray head from being blocked

A nozzle and marking technology, which is applied in the direction of coating, spraying device, and device for coating liquid on the surface, etc., can solve the problems of low operating efficiency, solidification of paint, and heavy maintenance workload of nozzles, and achieve low failure rate of nozzles. cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

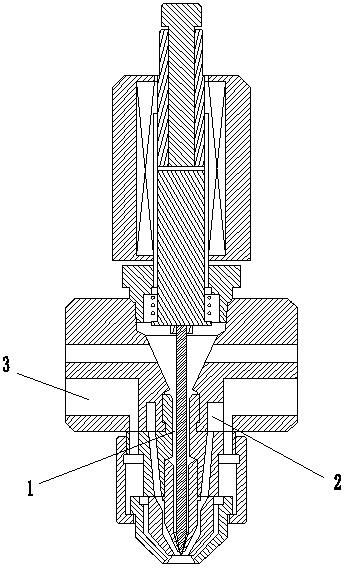

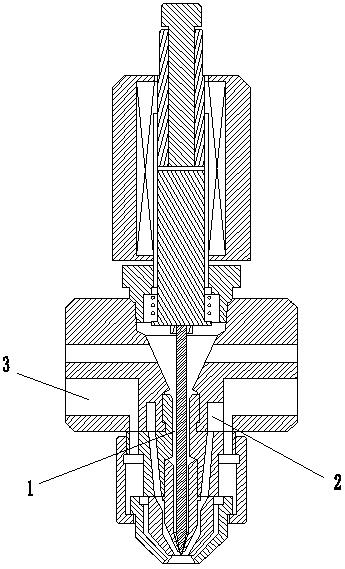

[0018] figure 1 It is a cross-sectional view of the nozzle structure of the heat marking machine.

[0019] In this embodiment, a spraying method for preventing nozzle clogging of a steel plate thermal marking machine comprises the following steps:

[0020] a. At the beginning of one spraying, the compressed air is continuously filled into the atomizing air cavity of the nozzle;

[0021] b. Open the paint nozzle of the nozzle and spray the paint;

[0022] c. Once the paint spraying is completed, close the paint nozzle;

[0023] d. Cut off the compressed air, and continuously feed the cooling water into the atomizing air chamber until the next spraying starts, and cut off the cooling water;

[0024] e. Repeat steps a to d until the marking operation is completed.

[0025] In this spraying method, during the spraying process, the spray head is continuously cooled by compressed air, and after the spraying is finished, the spray head is continuously cooled by cooling water, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com