Clamping spring structure of relay socket

A technology of relay socket and clip spring, which is applied in the field of structural improvement of the input port, can solve the problems of increasing difficulty, affecting the insertion of the relay, and the easy damage of the plastic partition wall 12', so as to improve the withstand voltage, facilitate the use, increase the The effect of width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

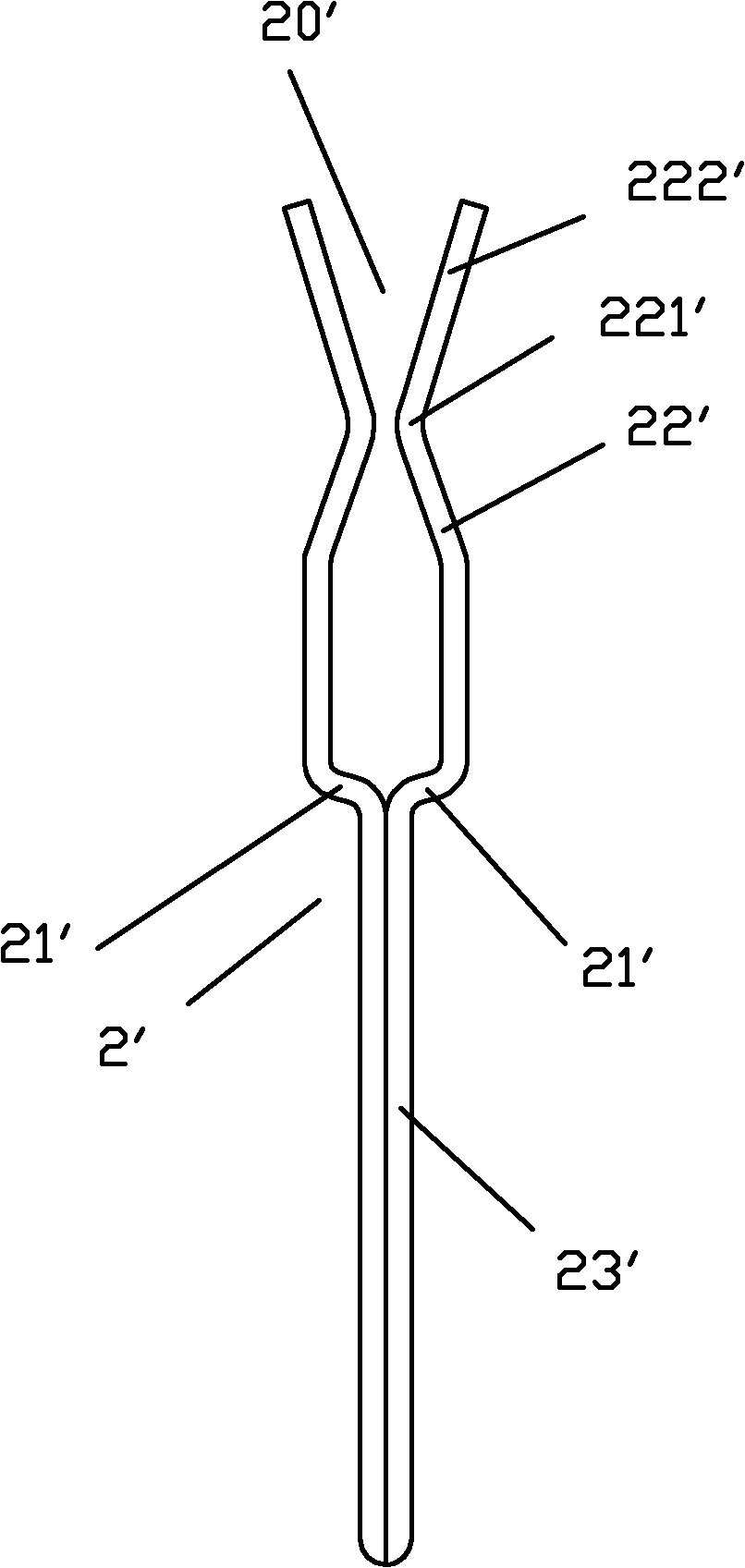

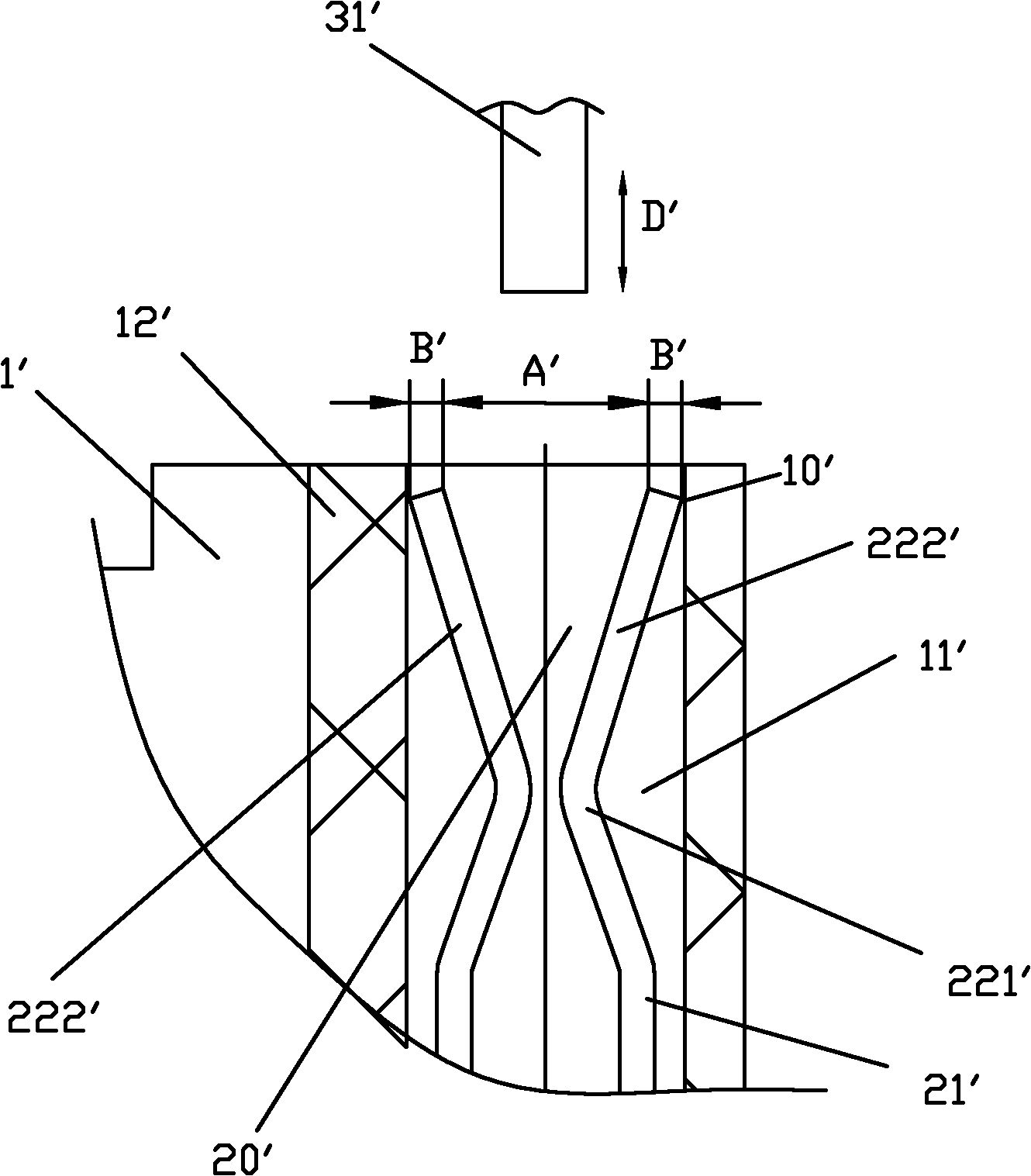

[0020] Examples, see Figure 6 to Figure 7 As shown, the clip spring structure of a kind of relay socket of the present invention, this clip spring 2 is made of two reeds 21 of strip-shaped alloy copper; Each end of two reeds 21 is set as free end 22, two reeds Each other end of 21 is connected as a whole to form opposite fixed end 23; A bending portion 221 is respectively provided in the middle part of the free ends of two leaf reeds 21, and this bending portion 221 just makes the end 222 of the free end of two leaf reeds form a V-shaped as the input port 20; when the relay lead pin is inserted, the input port 20 of the clip spring 2 can maintain a certain pressure on it. A chamfered surface 223 is respectively provided at the ends 222 of the free ends of the two reeds, and the chamfered surface 223 is arranged vertically.

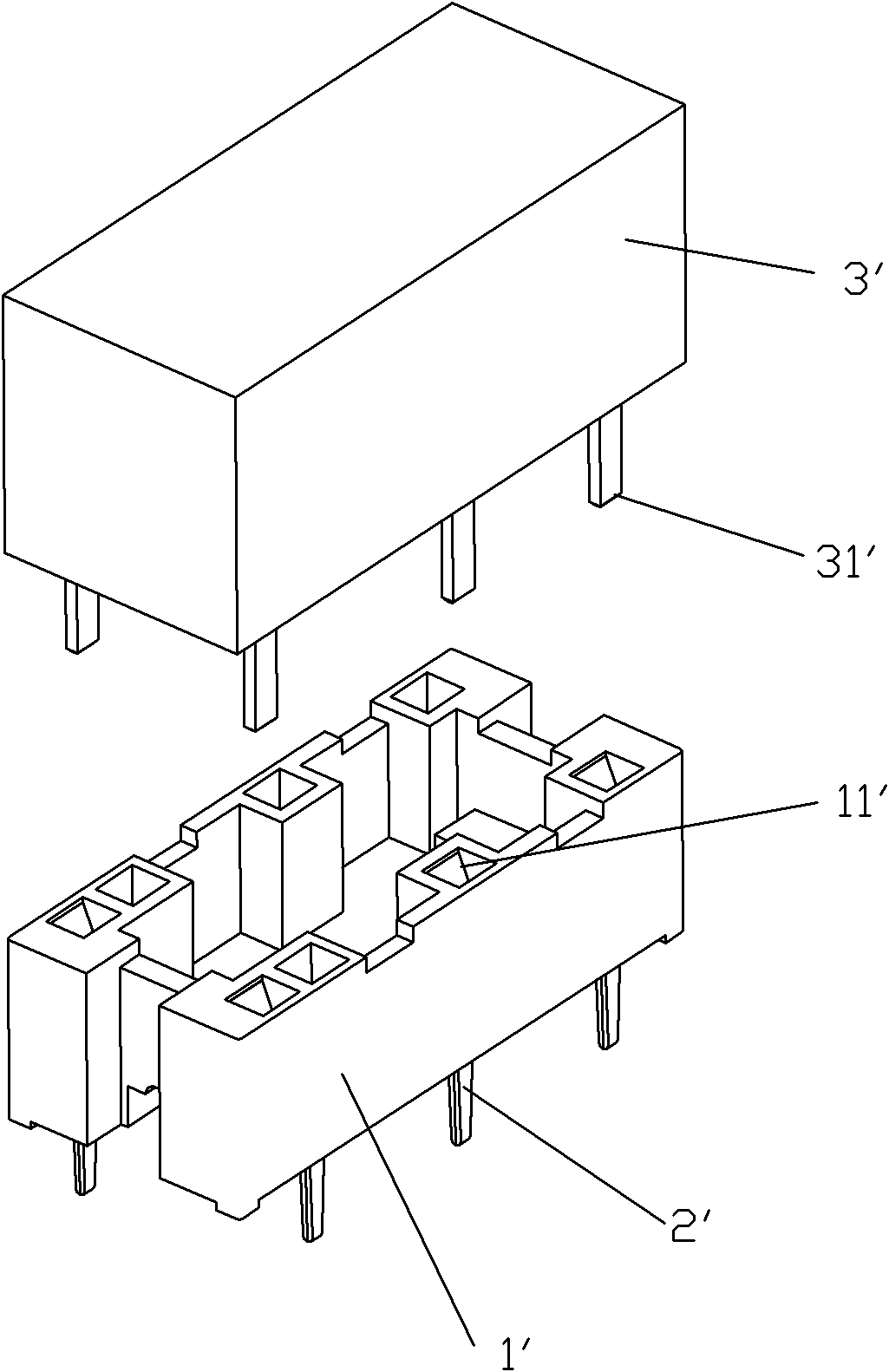

[0021] see Figure 5 to Figure 9 As shown, a kind of relay socket of the present invention comprises a base 1 and a clip spring 2; a slot 11 for instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com