Comprehensive intelligent check method of industrial distributed control system (DCS)

A distributed control and verification method technology, which is applied in the field of comprehensive intelligent verification of industrial distributed control systems, can solve the problem of the distance between the electronic room of the DCS cabinet and the engineer station, etc., and achieves simple methods, strong versatility and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

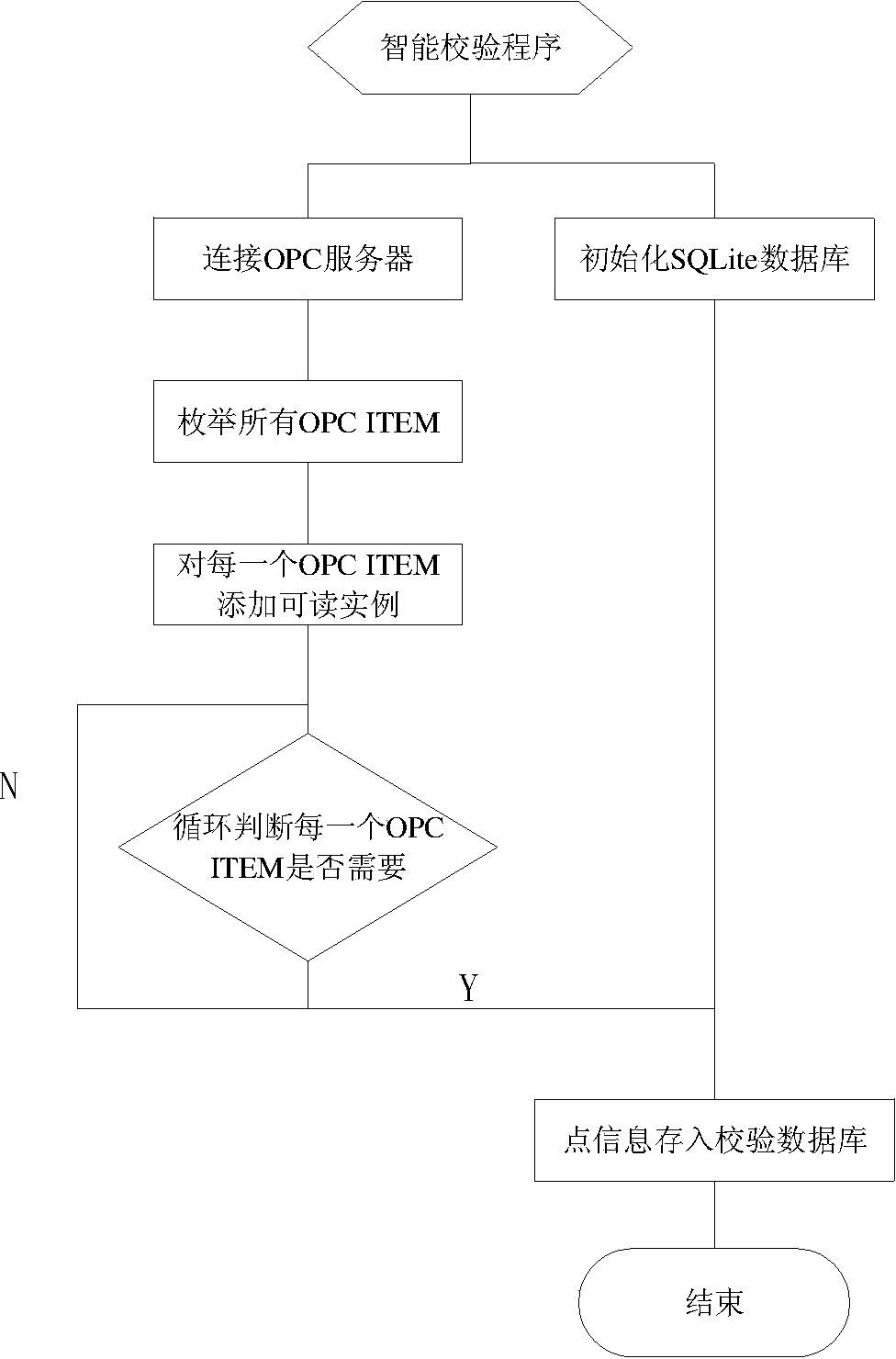

[0044] The concrete realization of this method comprises the following steps, see figure 1 .

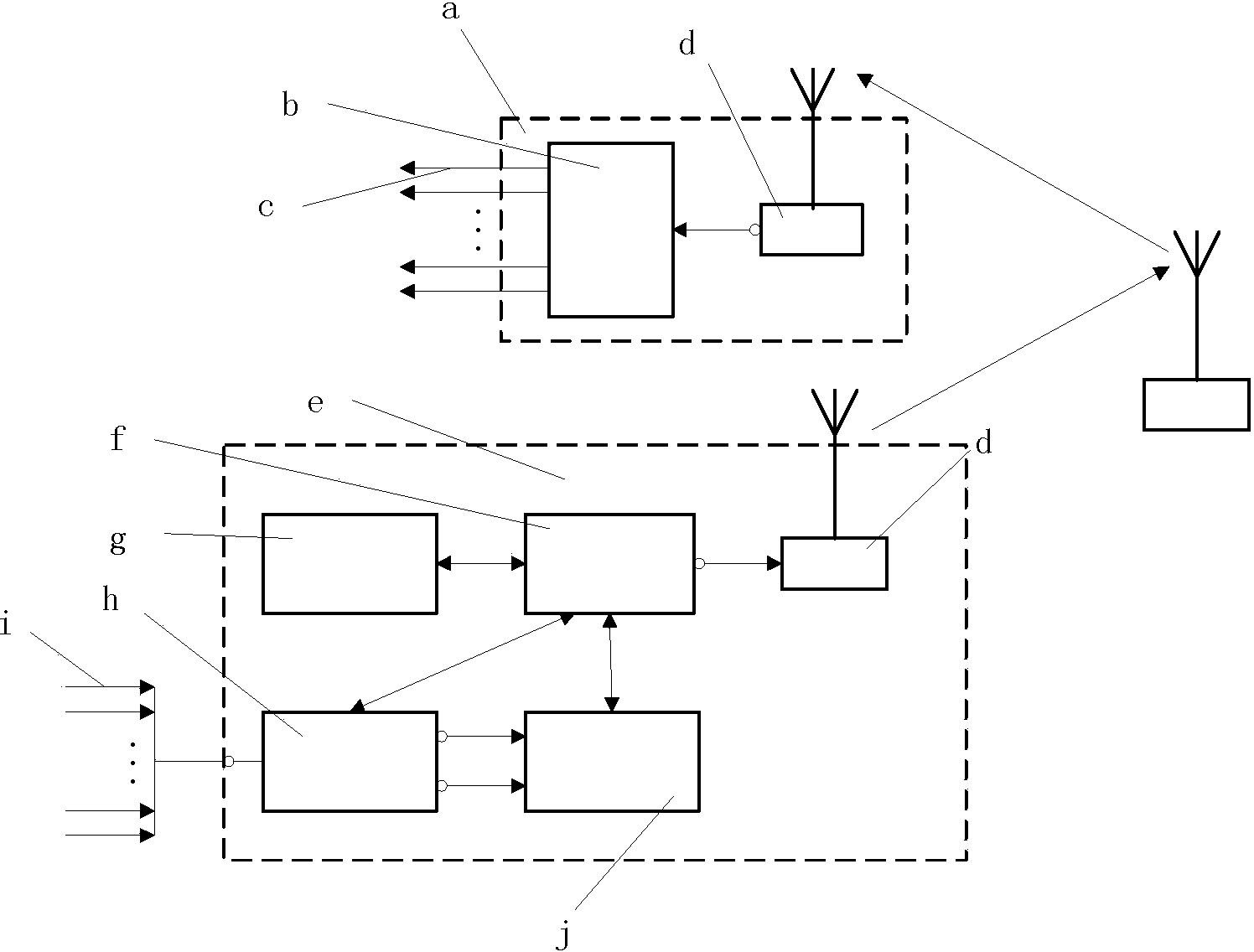

[0045] The DCS control system (1) includes the control cabinet (2), the control cabinet (2) includes different types of I / O cards (3), and the I / O cards (3) are composed of multiple I / O channels (4) composition. After the DCS card digitizes the industrial field signals, the data is sent to the DCS engineer station (5) for processing through the network bus, and the DCS system usually provides an OPC server (6), so that the data of the DCS system can be shared.

[0046]It can be divided into two parts, the terminal and the host. The terminal includes a standard signal drive module and related equipment, with a housing, a switch, a built-in standard signal source and its signal output line (for connecting to the I / O channel of the DCS system), Zigbee wireless transmission terminal (for wireless communication with the host); the host includes the OPC asynchronous communication data ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com