Method for constructing prediction model of heat conductivity coefficient of fully-graded concrete

A technology of thermal conductivity and prediction model, which is applied in the field of concrete construction, can solve the problems of large aggregate and specimen volume, no research model proposed, difficult thermal conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062]The invention will be further described below in conjunction with the description, but the scope of protection required by the present invention is not limited to the scope described in the embodiments.

[0063] Thermal Conductivity Test of Cement-Based Composite Materials

[0064] Test raw materials:

[0065] Cement Conch brand P.O42.5 fully graded Portland cement;

[0066] Sand River sand, with a fineness modulus of 2.3 and good particle gradation;

[0067] Granite slab..thickness is 10mm and 15mm;

[0068] Experimental protocol

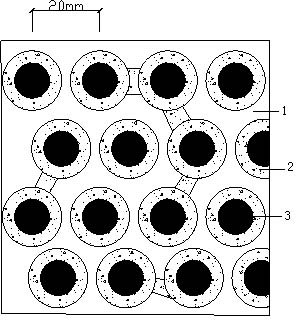

[0069] The measuring device adopts the device developed by our research group, see patent ZL200810122928 for details. The size of the test piece is 150mm×150mm×300mm. The mortar mix ratio used is shown in Table 1. The combination conditions of composite materials are shown in Table 2. The schematic diagram of composite materials is shown in Image 6 . After the pouring is completed, quickly move the specimen into the standard curing roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com