Actuator cylinder of built-in buffer load-reducing device

An actuating cylinder and load reduction technology, applied in the direction of fluid pressure actuating devices, etc., can solve the problems of fatigue damage, inability to adapt, and high temperature of the system oil, so as to reduce the process difficulty and manufacturing and use costs, avoid collisions and The effect of overload extrusion and improving performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

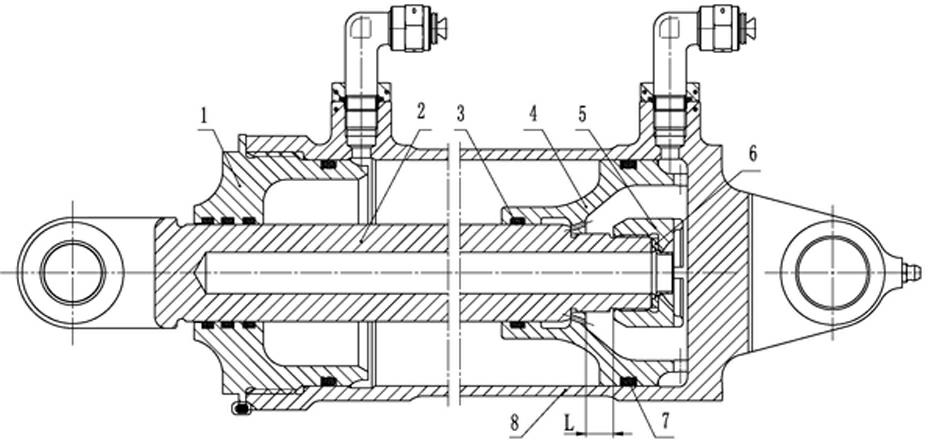

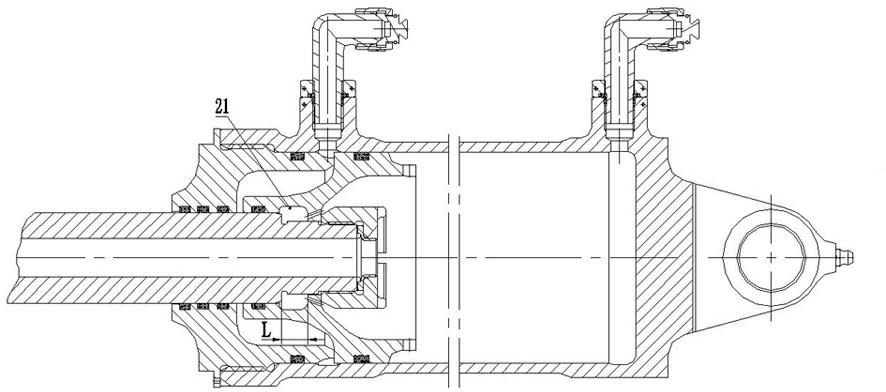

[0032] A cylinder with a built-in buffer and load reduction device, such as figure 1 , figure 2 , image 3 As shown, it includes a cylinder head 1, a cylinder body 8, a piston 4, a piston rod 2, a lock nut 5, and a self-locking retaining ring 6. Such as Figure 4 As shown, the piston rod 2 is provided with a stepped optical axis 9 , a threaded shaft 10 , and a stepped large axis end face 11 . Such as Figure 5 As shown, the inner hole at one end of the piston 4 is provided with a stepped hole 12 and a piston stepped small hole end face 19, an annular groove 13 is provided between the stepped holes 12, a sealing groove 14 is provided in the large stepped hole, and the other end of the piston is provided with The inner groove 20 and the groove end surface 17, the inner groove 20 communicates with the stepped hole 12, a plurality of evenly distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com