Maritime foundation base

A foundation and foundation technology, applied in the field of infrastructure structures, can solve the problems of high offshore construction costs, restrictions on the development of offshore wind power, and high requirements for bearing foundations, and achieve the effects of avoiding excessive material consumption, improving anti-vibration safety, and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the above-mentioned objectives, features and advantages more obvious and understandable, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

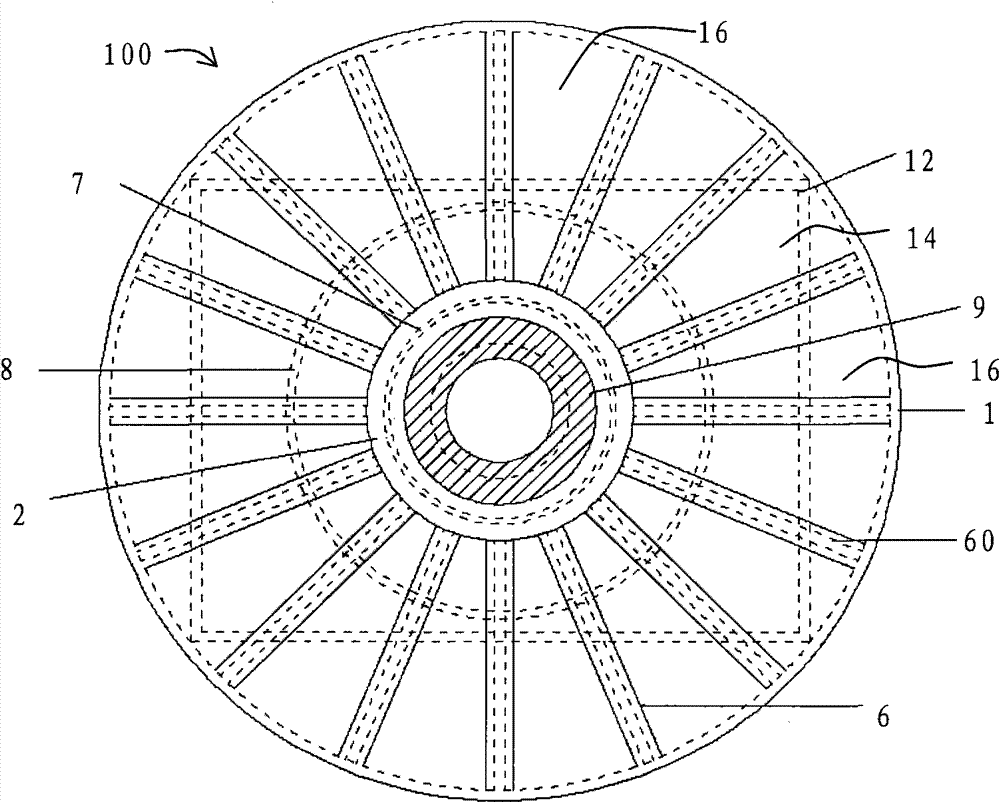

[0034] figure 1 It is a cross-sectional view of an offshore foundation according to an embodiment of the present invention. figure 2 Yes figure 1 The top view of the foundations in the sea. Such as figure 1 with figure 2 As shown, the offshore foundation 100 of an embodiment of the present invention includes a cylindrical foundation 1 and a connecting tower 2 located above the cylindrical foundation 1. The top of the connecting tower 2 is provided with a flange ring 9, and the connecting tower 2 is connected to the generator set tower 3 through the flange ring 9.

[0035] The cylindrical foundation 1 is a reinforced concrete structure. A sealing top cover 10 is provided on the upper part of the cylindrical foundation 1. The connecting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com