Sponge iron-AT (Attapulgite)-PVF (Polyvinyl Fluoride) composite filler and application thereof on water treatment

A -AT-PVF, composite filler technology, applied in sponge iron-AT-PVF composite filler and its application in water treatment, can solve the problems of single effect, poor practicability and high cost, achieve biomass increase, overcome Adverse effects, effects of high biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

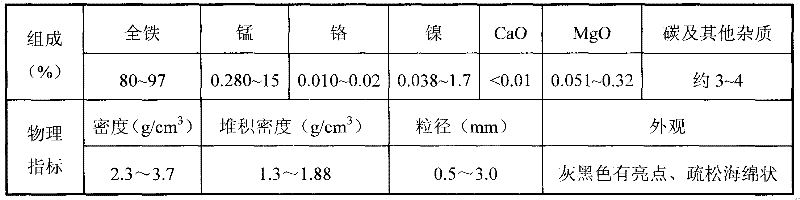

Image

Examples

Embodiment 1

[0029] Example 1 Sponge iron-AT-PVF composite filler, characterized in that: the composite filler is cut into 1.5cm×1.5cm×1.5cm attapulgite composite hydrophilic polyurethane foam and a sponge with a particle size of 2-5cm Iron is evenly filled in a weight ratio of 1:4.

[0030] Among them: attapulgite composite hydrophilic polyurethane foam is composed of the following raw materials in parts by weight:

[0031] Polyether 100 toluene diisocyanate 50 polyisocyanate 3.1

[0032] Nano Attapulgite 4 Silicone Oil 0.45 Tertiary Amine 0.25

[0033] Organotin 0.14 Water 2.0 Dichloromethane (MC) 4.5

[0034] N,N dimethylformamide (DMF) 40;

[0035] The preparation method of the nano attapulgite composite hydrophilic polyurethane foam microbial immobilization carrier includes the following steps:

[0036] (1) The purified attapulgite raw soil produced by Jiangsu Xuyi Guangming Attapulgite Factory is crushed to particles with a particle size of less than 100μm with an ordinary ball mill. Take 4 pa...

Embodiment 2

[0042] Example 2 Sponge iron-AT-PVF composite filler, characterized in that: the composite filler is cut into 1.5cm×1.5cm×1.5cm attapulgite composite hydrophilic polyurethane foam and a sponge with a particle size of 2-5cm Iron is evenly filled in a weight ratio of 1:50.

[0043] Among them: attapulgite composite hydrophilic polyurethane foam is composed of the following raw materials in parts by weight:

[0044] Polyether 100 Toluene diisocyanate 45 Polyisocyanate 3.9

[0045] Nano Attapulgite 5 Silicone Oil 1.2 Tertiary Amine 0.20

[0046] Organotin 0.20 Water 2.5 MC 2.3 DMF 60;

[0047] The preparation method of the nano attapulgite composite hydrophilic polyurethane foam microbial immobilization carrier and sponge iron are the same as those in Example 1.

Embodiment 3

[0048] Example 3 Sponge iron-AT-PVF composite filler, characterized in that: the composite filler is cut into 1.5cm×1.5cm×1.5cm attapulgite composite hydrophilic polyurethane foam and a sponge with a particle size of 2-5cm Iron is evenly filled in a weight ratio of 1:27.

[0049] Among them: attapulgite composite hydrophilic polyurethane foam is composed of the following raw materials in parts by weight:

[0050] Polyether 100 toluene diisocyanate 38 polyisocyanate 3.1

[0051] Nano attapulgite 2 Silicone oil 0.85 Tertiary amine 0.14 Organotin 0.15

[0052] Water 1.0 MC 1.6 DMF 30;

[0053] The preparation method of the nano attapulgite composite hydrophilic polyurethane foam microbial immobilization carrier and sponge iron are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com