Pneumatic tire

A pneumatic tire, tire circumferential technology, applied in the direction of the reinforcement layer of the pneumatic tire, tire parts, tire tread/tread pattern, etc., can solve the problem that the studless tire has no inspiration, is difficult, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] Next, examples and the like that specifically illustrate the configuration and effects of the present invention will be described. In addition, the evaluation items of an Example etc. were measured as follows.

[0043] (1) Snow performance

[0044] The test tires were mounted on an actual vehicle (domestic passenger car), and the vehicle was driven on an icy and snowy road, and the braking distance when the ABS was activated by applying a braking force from an entry speed of 40 km / h was measured. Taking the result of Comparative Example 1 as 100, the reciprocal of the measured value was indexed. The larger the index, the better the snow performance (especially the braking performance).

[0045] (2) Dry performance

[0046] Test tires were mounted on the above-mentioned actual vehicles, and cornering and braking were carried out on a test road with dry ground, and the steering stability, cornering performance and braking performance were evaluated by the driver's senso...

Embodiment 1~4

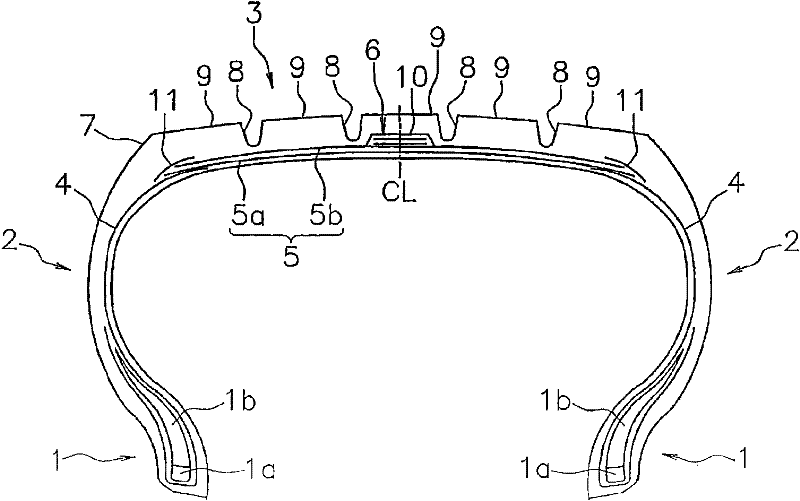

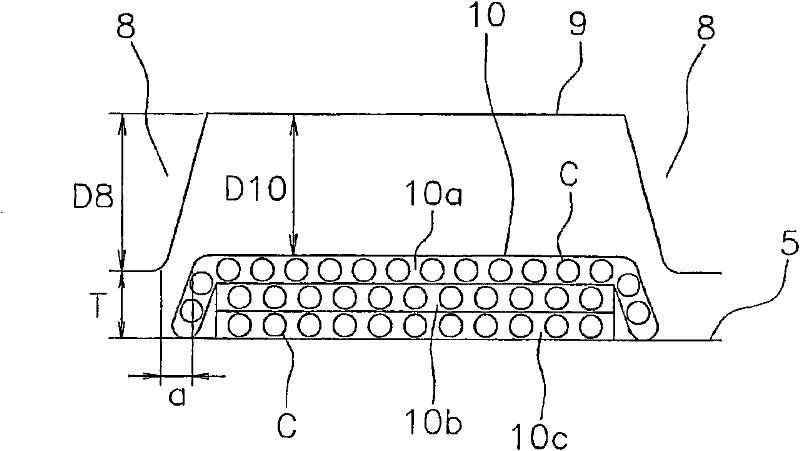

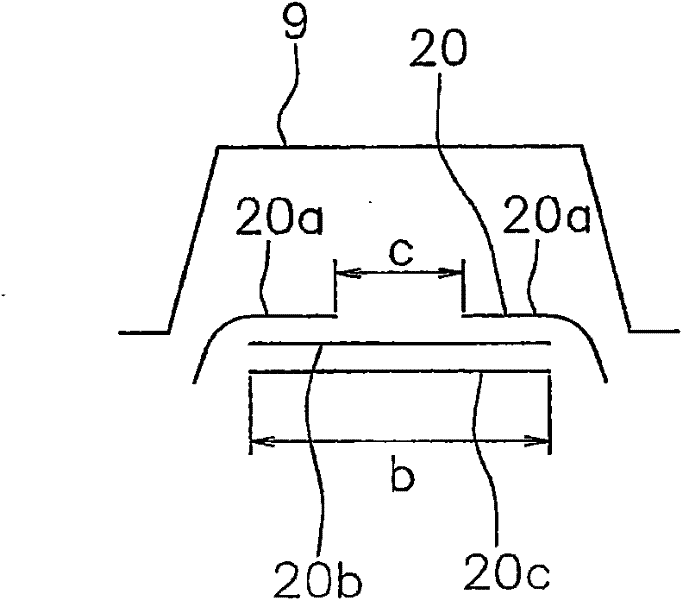

[0052] Example 1 is formed to adopt a single cap reinforcement structure in the same manner as Comparative Examples 2 and 3, and arrange such as figure 2 The illustrated reinforcement lamination is the same as Comparative Example 1 except for this. In addition, Embodiment 2 is formed, except that the reinforcement laminated portion is as Figure 3a Except for the structure shown, it is the same as in Example 1. In addition, Example 3 is formed, except that the reinforcement laminated portion is as Figure 4 Except for the structure shown, it is the same as in Example 1. Embodiment 4 is formed so that, instead of a single cap reinforcement structure, such as figure 1 It is the same as that of Example 1 except for a pair of reinforcing end portions covering both ends of the belt layer in this way.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com