Pneumatic seed shooting mechanism and automatic control method thereof

A kind of seeding and pneumatic technology, which is applied in the direction of interval-type quantitative seeding machinery, etc., can solve the problems of unstable transmission power, reduce the working efficiency of the seeder, affect the coordination between seeding and air pressure seeding, and achieve the power source of the system. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

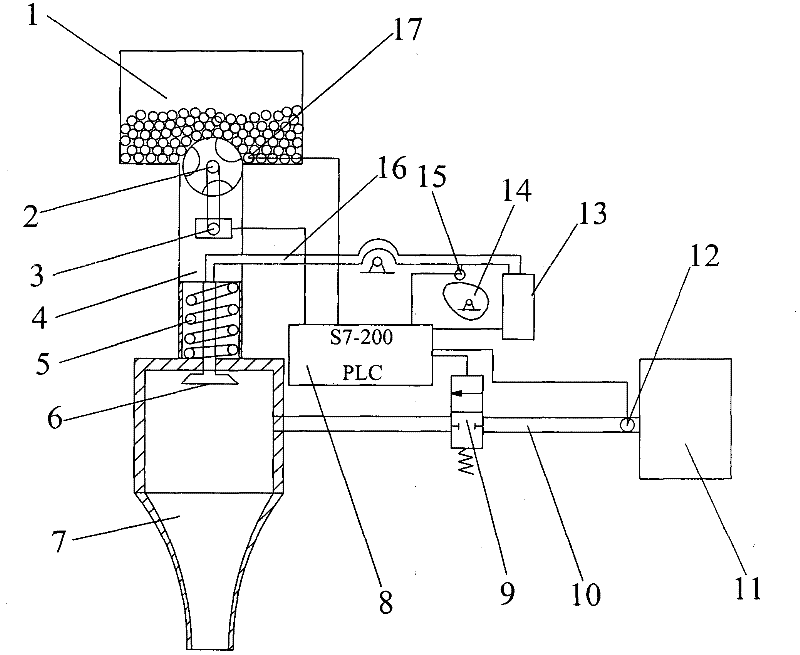

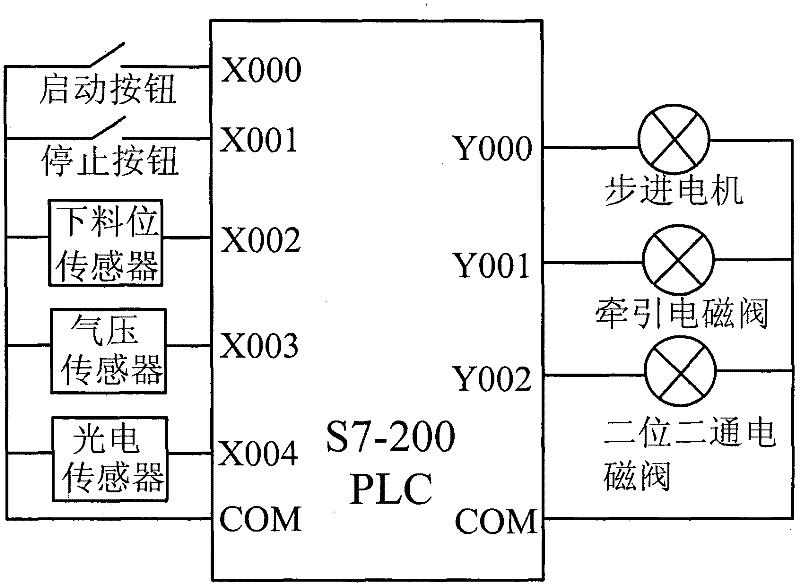

[0017] Example 1, such as figure 1 As shown, the pneumatic seed injection mechanism controlled by PLC includes: seed box 1, seed meter 2, stepper motor 3, seed delivery pipe 4, seed meter valve 6, seed chamber 7, PLC controller 8 , 2-position 2-way solenoid valve 9, exhaust pipe 10, gas tank 11, air pressure sensor 12, traction electromagnet 13, cam 14, photoelectric sensor 15, seed valve lever 16, material level sensor 17;

[0018] The control system includes a PLC controller 8, a stepper motor 3 is installed on the seed-discharging shaft, a material level sensor 17 is installed at the bottom of the right side of the seed box 1, and a traction electromagnet 13 is installed at the end of the seed-discharging valve lever 16. A two-position two-way electromagnetic valve 9 is installed on the exhaust pipe 10 at the right end of the injection chamber 7 and an air pressure sensor 12 is installed at the outlet of the gas tank 11, and a photoelectric sensor 15 is installed on the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com