Method of designing tire and tire

A design method and tire technology, applied in the direction of tire tread/tread pattern, tire parts, transportation and packaging, etc., can solve the problems of loss of performance, affecting the freedom of tread pattern design, etc., and achieve the effect of reducing tire noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

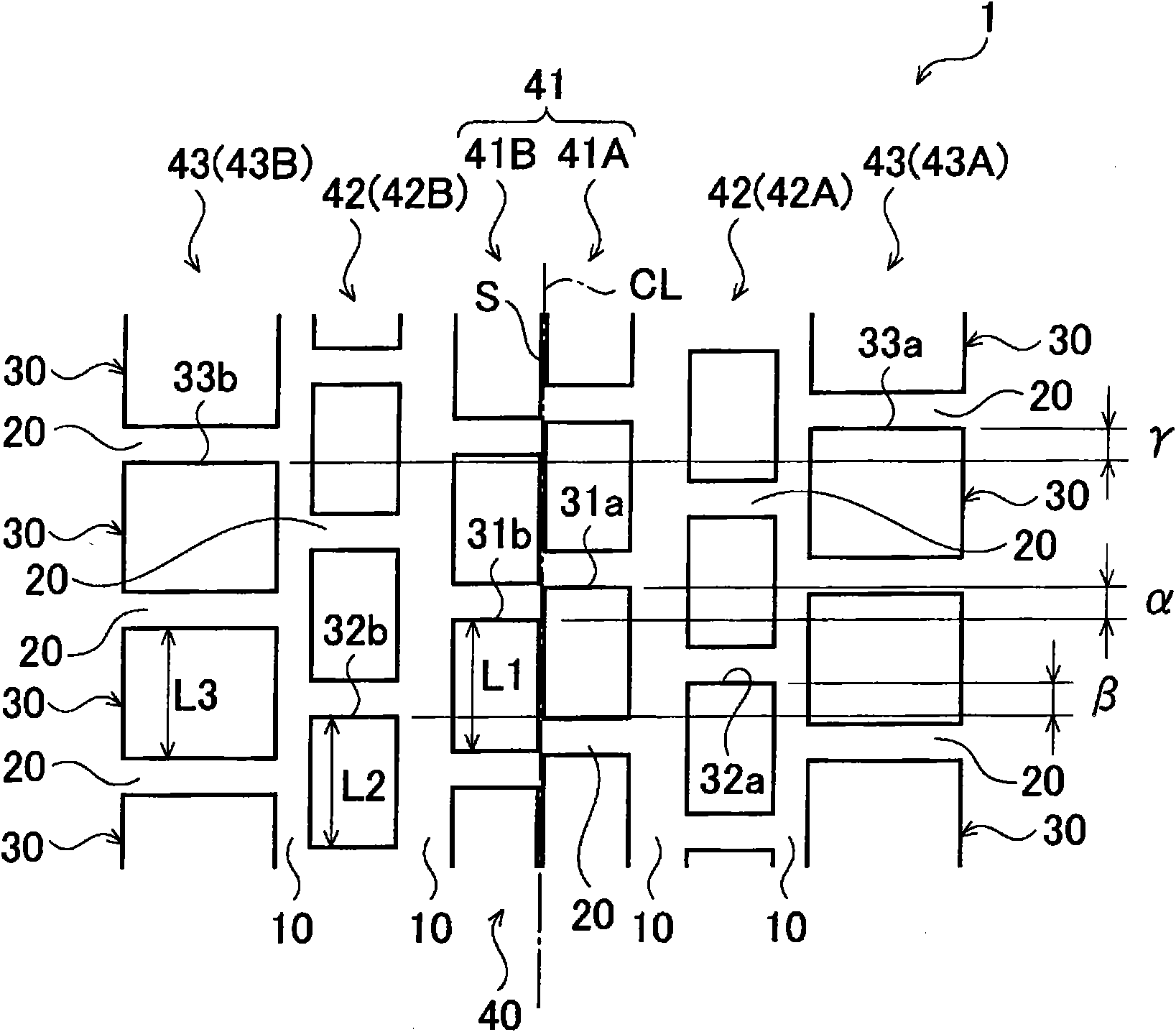

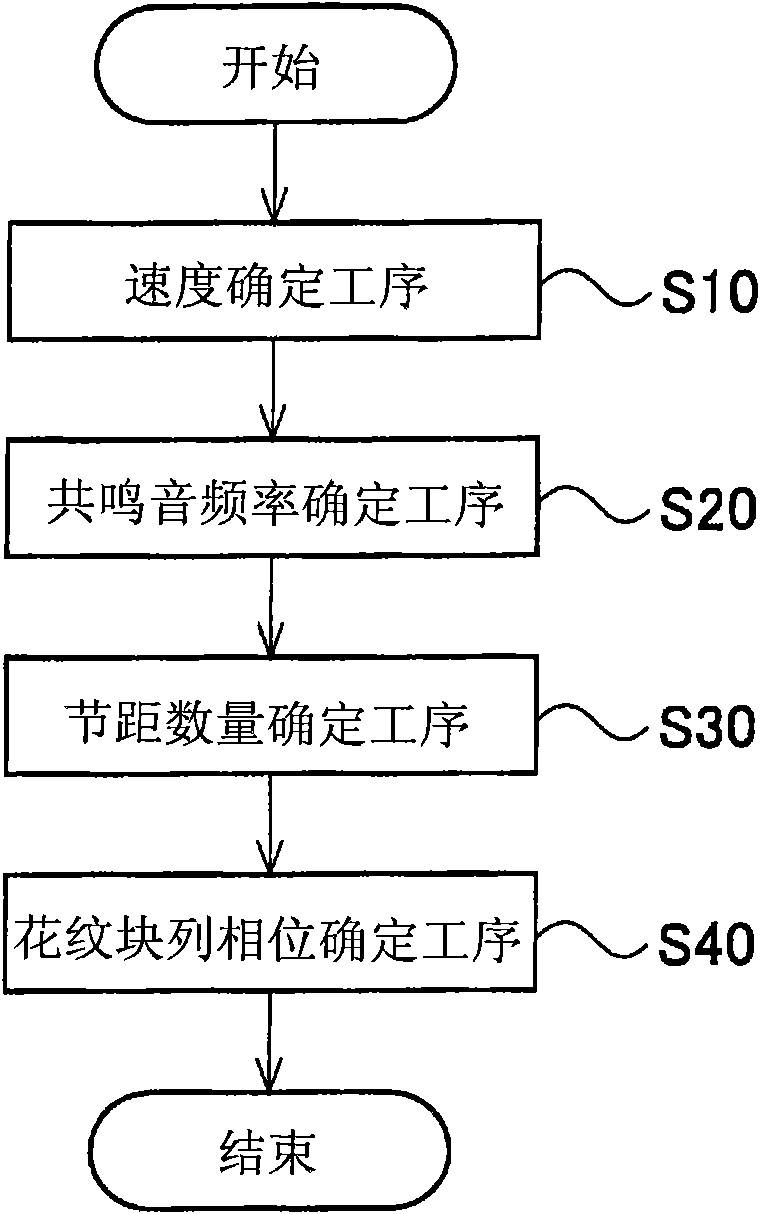

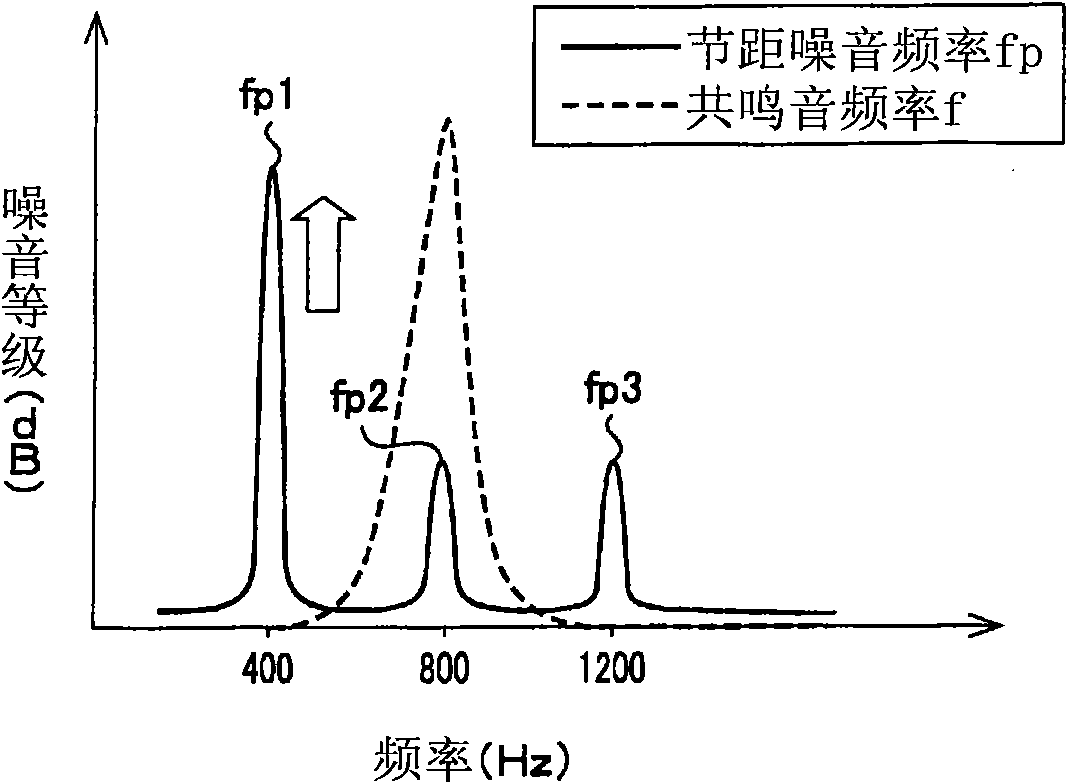

[0031] Next, an embodiment of a tire design method and a tire (pneumatic tire) according to the present invention will be described with reference to the drawings. In detail, (1) structure of a pneumatic tire, (2) tire design method, (3) operation and effect, (4) comparative evaluation, and (5) other embodiments will be described.

[0032] In addition, in the following drawings, the same or similar code|symbol is attached|subjected to the same or similar part. However, the drawings are schematic diagrams, and it should be noted that the ratio of each dimension is different from the real thing.

[0033] Therefore, specific dimensions and the like must be judged with reference to the following description. In addition, it is needless to say that there are parts in which the dimensional relationship is different and the ratio is different between the respective drawings.

[0034] (1) Structure of pneumatic tire

[0035] First, the configuration of a pneumatic tire 1 according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com