Screw tightening device and torque sensor

A torque sensor and fastening device technology, which is applied in measuring devices, torque measurement, instruments, etc., can solve problems such as difficulty in one-handed operation, achieve the effects of reducing reaction force, increasing torque, and reducing burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

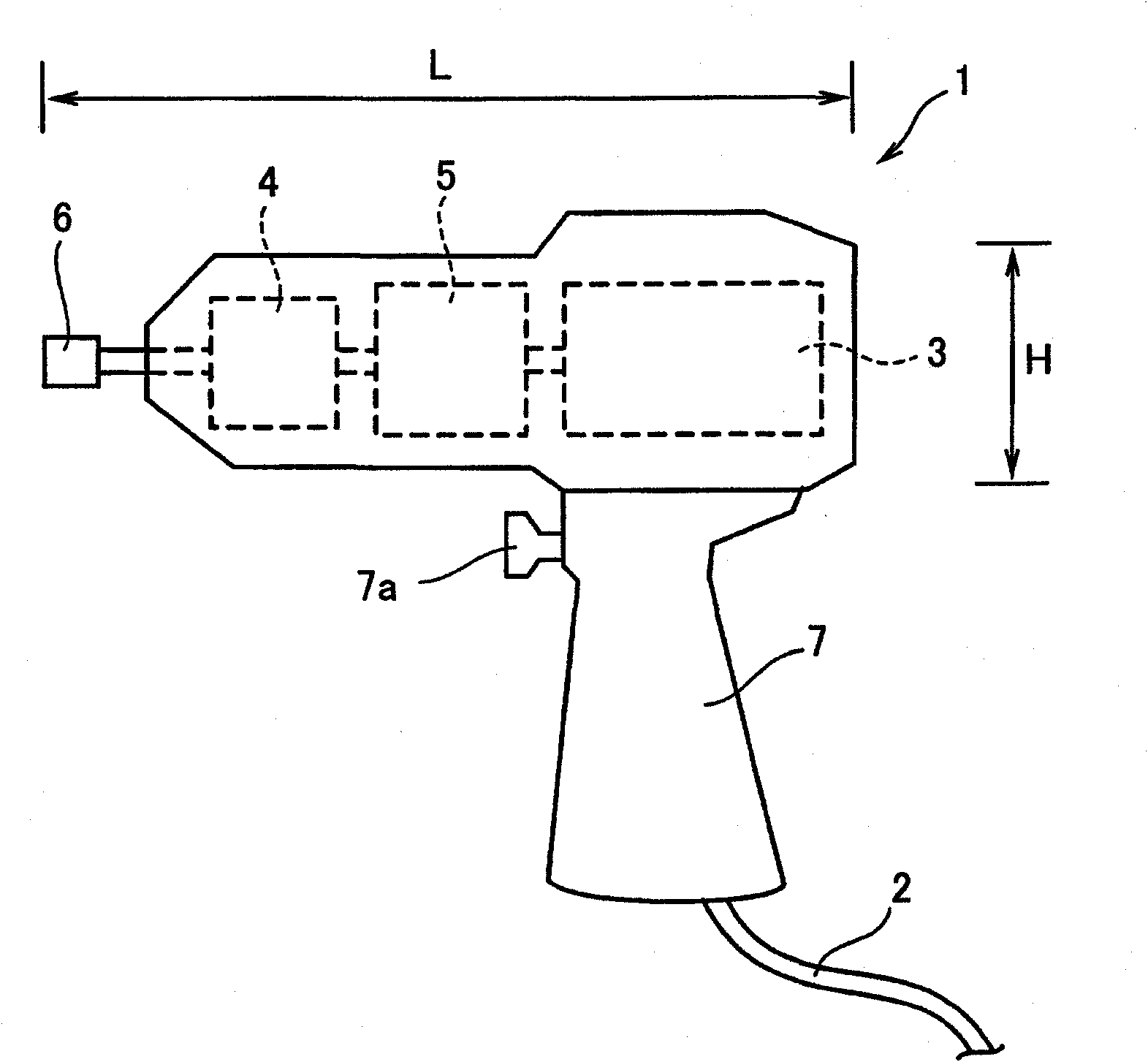

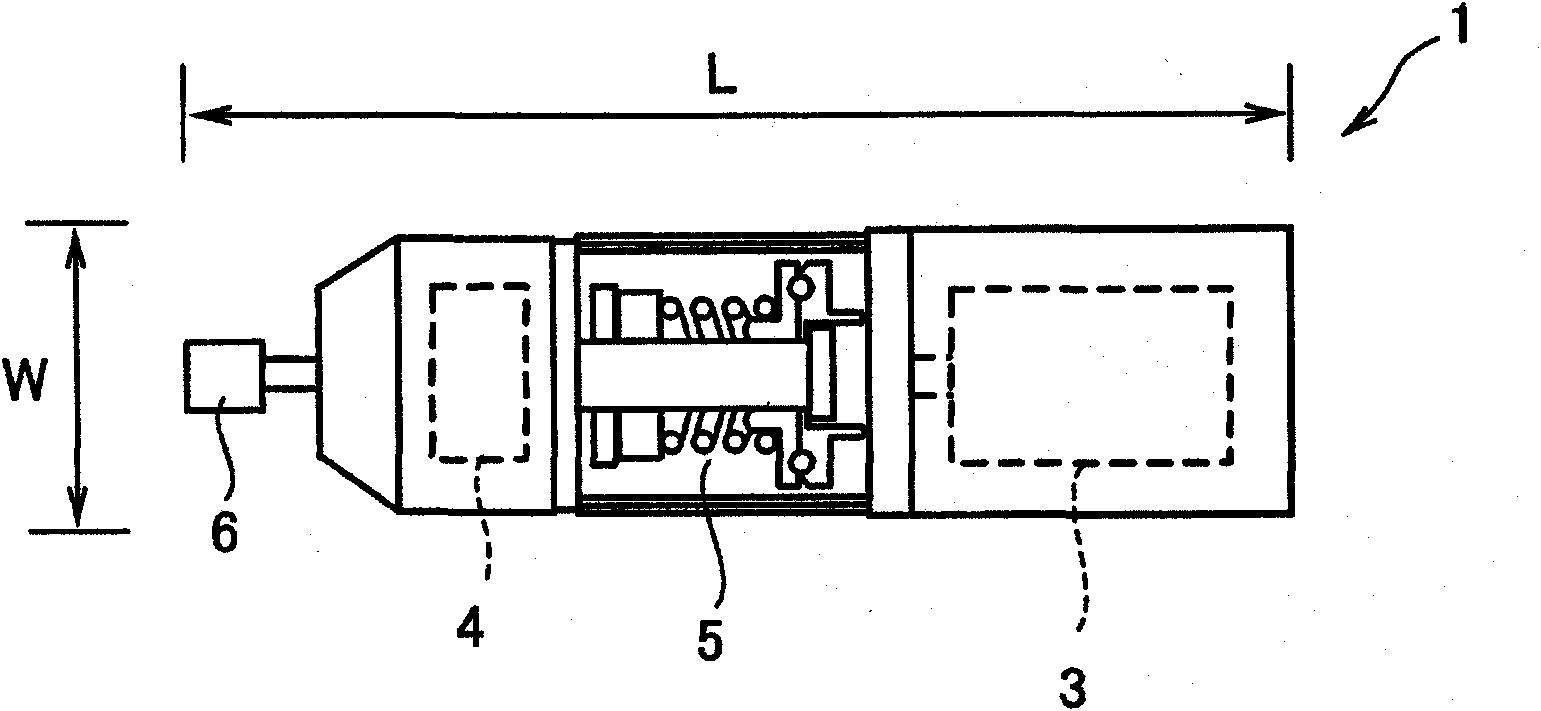

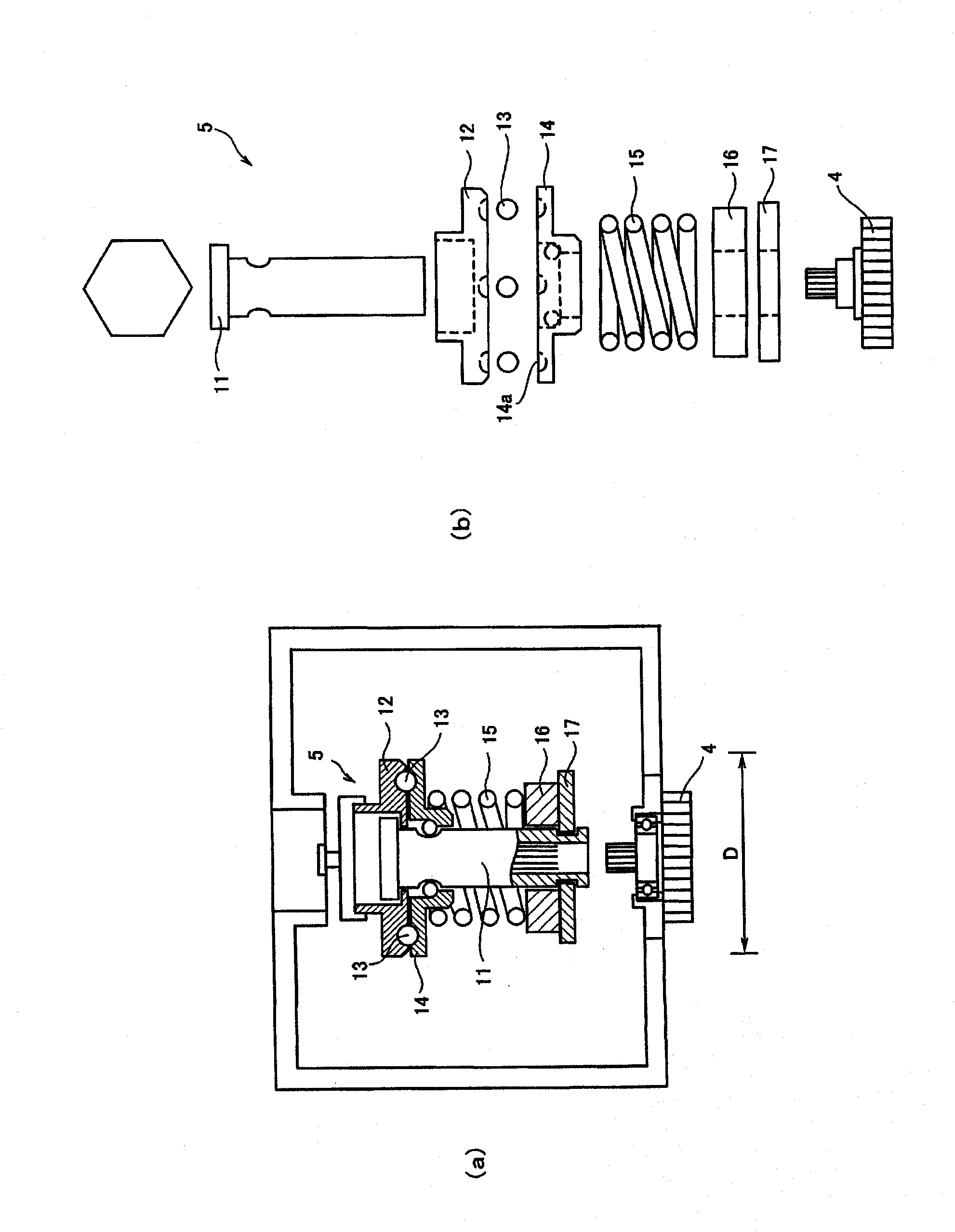

[0045] Embodiments of the present invention will be described below with reference to the drawings. here, figure 1 It is a brief side view of the screw fastening device of the first invention, figure 2 It is a brief top view of the screw fastening device of the first invention, image 3 It is an explanatory diagram of the clutch, Figure 4 is an explanatory diagram of the limit plate, Figure 5 This is an explanatory diagram of the operation of the displacement switch.

[0046] Such as figure 1 and figure 2 As shown, the screw fastening device of the present invention includes: a pistol-shaped device main body 1, a controller (not shown) that controls a direct current (DC) motor 3 constituting the device main body 1, a lithium ion battery (not shown) as a power source As shown in the figure), the cable 2 connecting the main body of the device 1 and the controller. The controller and the battery may be attached to a belt wrapped around the worker's waist, or may be ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com