Modularized flux switching permanent magnet (FSPM) motor

A magnetic flux switching, permanent magnet motor technology, applied in the direction of magnetic circuit static parts, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of magnetic flux switching motors that have not been published publicly and affect the rotor. Mechanical strength, increase the production process and other issues, to achieve the effect of compact structure, simple structure, and improved cooling conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

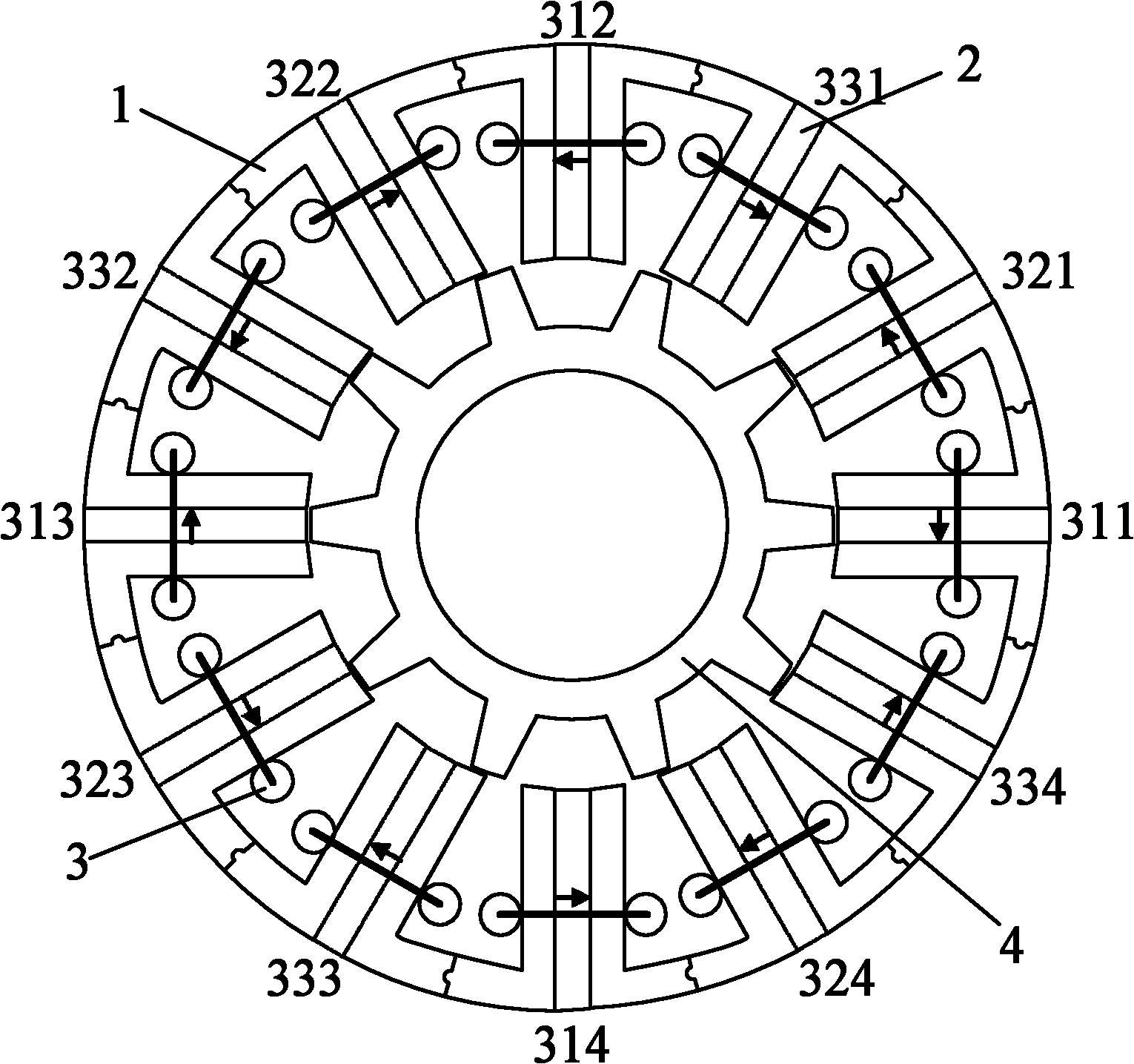

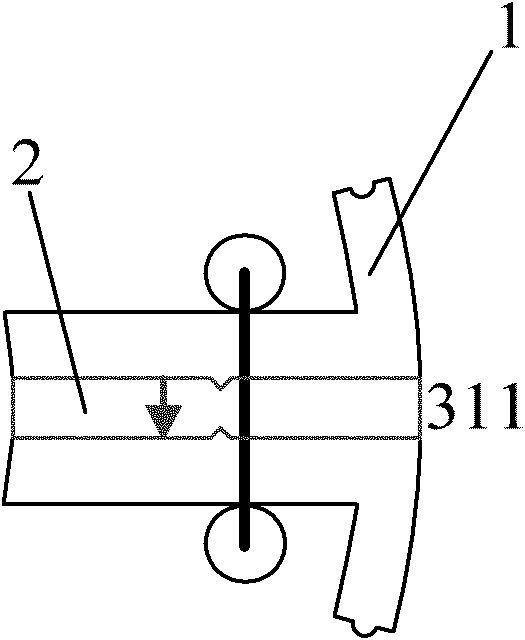

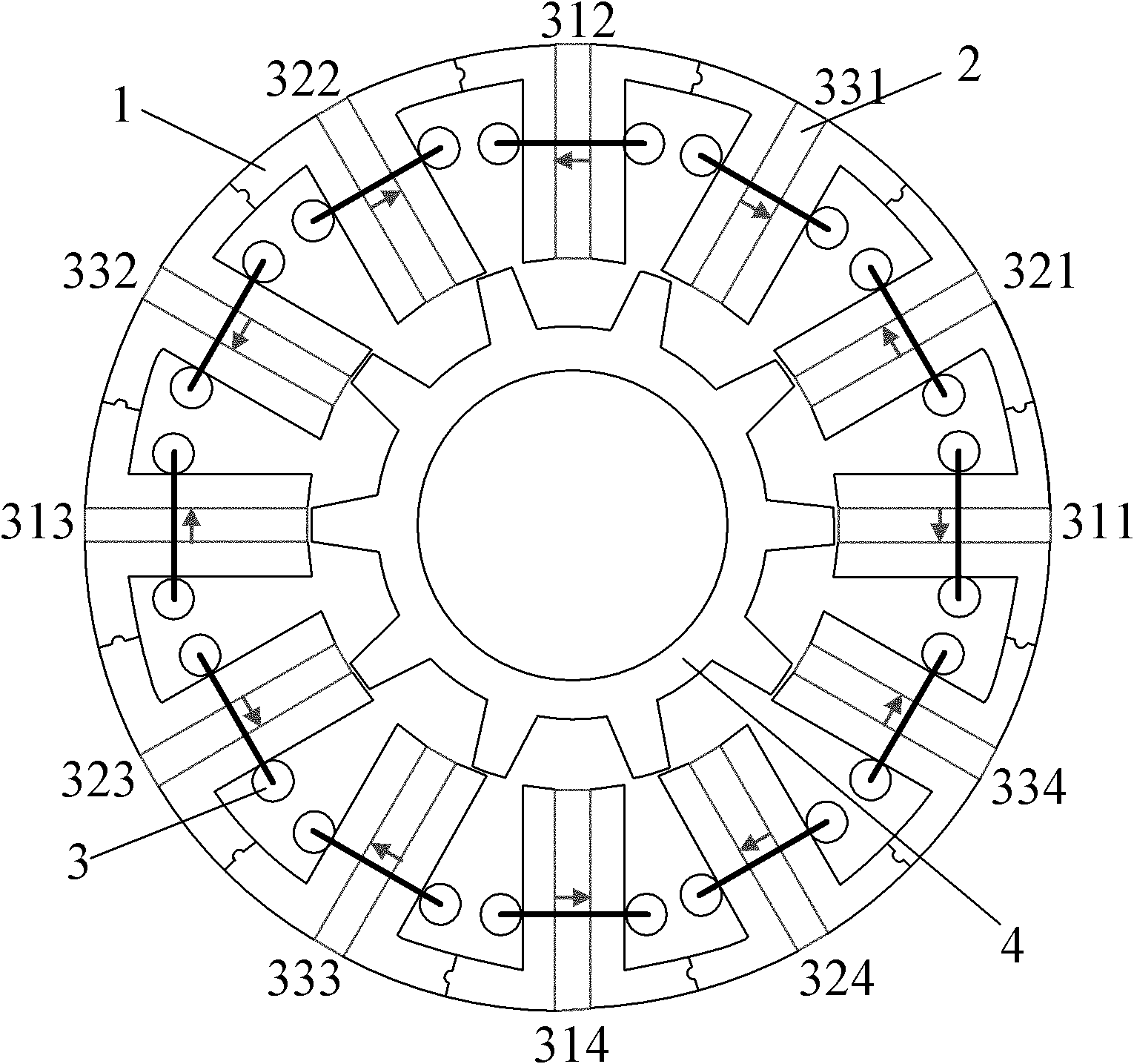

[0026] like figure 1 Shown is a three-phase (A-phase, B-phase, C-phase) modular flux switching permanent magnet motor, including a stator 1 core and a rotor 4 core, the rotor 4 is located inside the stator 1, and both the stator 1 and the rotor 4 are Salient pole structure, stator 1 has twelve slots, and rotor 4 has ten teeth; stator 1 is composed of twelve magnetic modules installed in the stator core slot; the magnetic module consists of two magnetic cores, one male and one female, and A permanent magnet 2 is arranged between them; a concentrated winding 3 is wound on the magnetic module.

[0027] The permanent magnet 2 is ferrite, samarium cobalt or neodymium iron boron permanent magnet steel, and both the stator core and the salient pole rotor 4 can be made by pressing and laminating silicon steel sheets.

[0028] The A-phase first winding coil 311 and the third winding coil 313 of the concentrated winding 3 are diametrically opposite, and the second winding coil 312 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com