GaN-based light emitting diode and preparation method thereof

A technology of light-emitting diodes and emission layers, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of sensitive luminous performance, difficult control of triangular quantum wells, and the stability and repeatability of LED devices need to be improved, so as to improve the luminescence Efficiency, improvement of light output reliability and repeatability, effects of mitigating polarization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

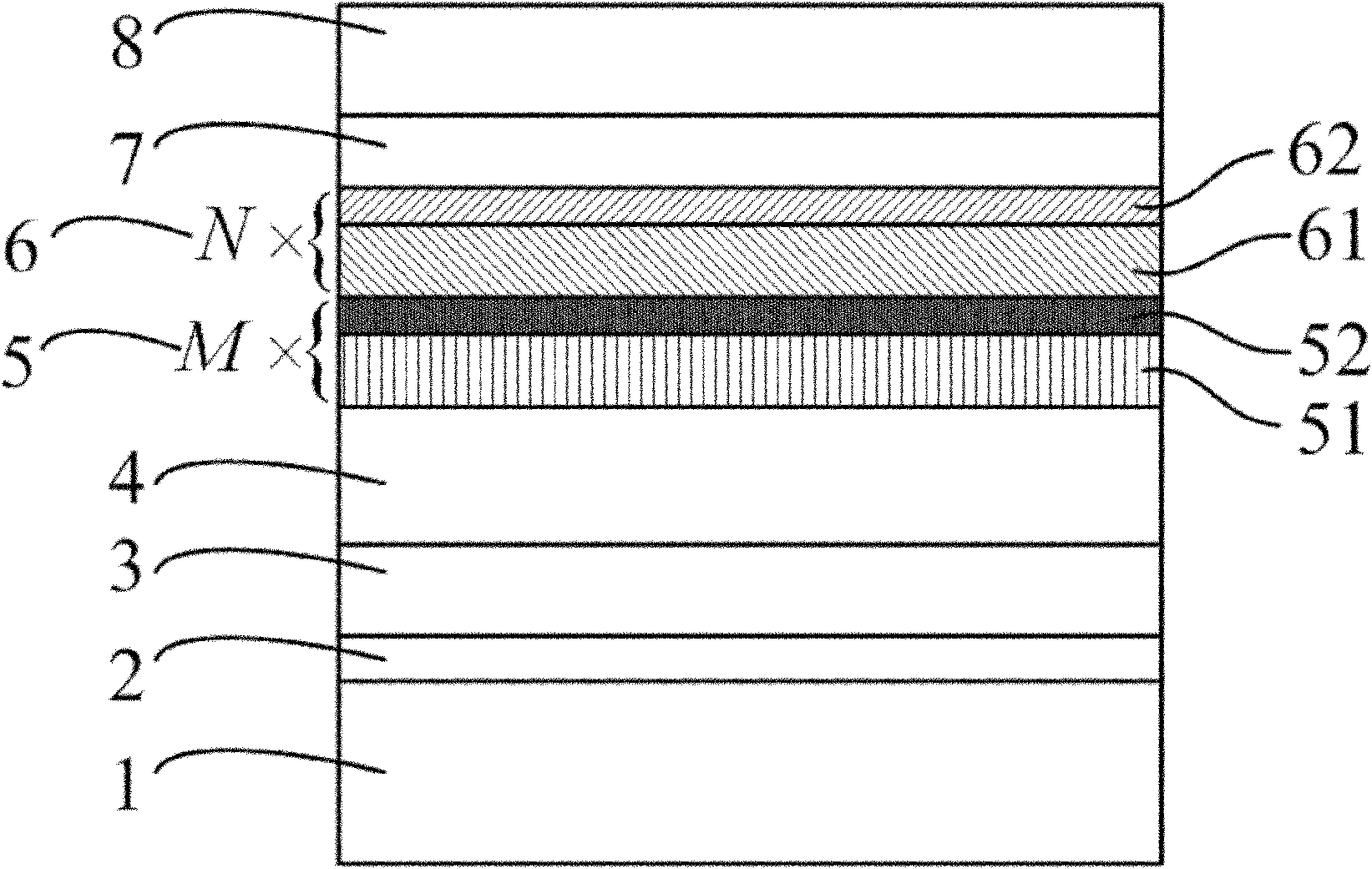

[0047] 1. Using ordinary metal oxide vapor deposition (MOCVD) equipment, the substrate material 1 is a sapphire non-patterned (0001) surface substrate; heat at high temperature to clean the substrate; then lower the temperature to grow the GaN initial growth layer 2. The thickness is 20nm;

[0048] 2. On the basis of step 1, raise the temperature, recrystallize the GaN layer, and then grow sequentially:

[0049] GaN buffer layer 3, which is a non-doped GaN layer with a thickness of 1 μm;

[0050] n-type electron injection layer 4, which is a Si-doped GaN layer with a thickness of 2.3 μm;

[0051] 3. On the basis of step 2, the temperature is reduced to grow the shallow quantum well structure electron emission layer 5, and a total of 3 periods of barrier layers 51 and shallow quantum well layers 52 are grown; wherein:

[0052] The barrier layer 51 is a Si-doped GaN material with a thickness of 7nm;

[0053] The shallow quantum well layer 52 is InGaN with a triangular structu...

Embodiment 2

[0060] 1. Using ordinary metal oxide vapor deposition (MOCVD) equipment, the substrate material 1 is a non-patterned silicon (0001) surface substrate; heat at high temperature to clean the substrate; then lower the temperature to grow AlN initial growth Layer 2 with a thickness of 50nm;

[0061] 2. On the basis of step 1, heat up and grow sequentially:

[0062] GaN buffer layer 3, which is a non-doped GaN layer with a thickness of 1 μm;

[0063] n-type electron injection layer 4, which is a Si-doped GaN layer with a thickness of 2.3 μm;

[0064] 3. On the basis of step 2, reduce the temperature to grow the shallow quantum well structure electron emission layer 5, and grow a total of 3 cycles, the barrier layer 51 and the shallow quantum well layer 52; wherein:

[0065] The barrier layer 51 is a Si-doped AlInGaN material with a thickness of 7nm;

[0066] The shallow quantum well layer 52 is InGaN with a triangular structure, that is, the non-doped InGaN whose In composition ...

Embodiment 3

[0074] 1. Using ordinary metal oxide vapor deposition (MOCVD) equipment, the substrate material 1 is a patterned sapphire substrate, the pattern is a hemispherical pattern arranged regularly, and the growth surface is a (0001) surface; clean the substrate at high temperature; then put Lowering the temperature to grow GaN initial growth layer 2 with a thickness of 20nm;

[0075] 2. On the basis of step 1, increase the temperature to recrystallize the GaN layer, and then grow sequentially:

[0076] GaN buffer layer 3, which is a non-doped GaN layer with a thickness of 3 μm;

[0077] n-type electron injection layer 4, which is a Si-doped GaN layer with a thickness of 2 μm;

[0078] 3. On the basis of step 2, reduce the temperature to grow the shallow quantum well structure electron emission layer 5, and grow a total of 3 cycles, the barrier layer 51 and the shallow quantum well layer 52;

[0079] Wherein: the barrier layer 51 is a Si-doped GaN material with a thickness of 7nm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com