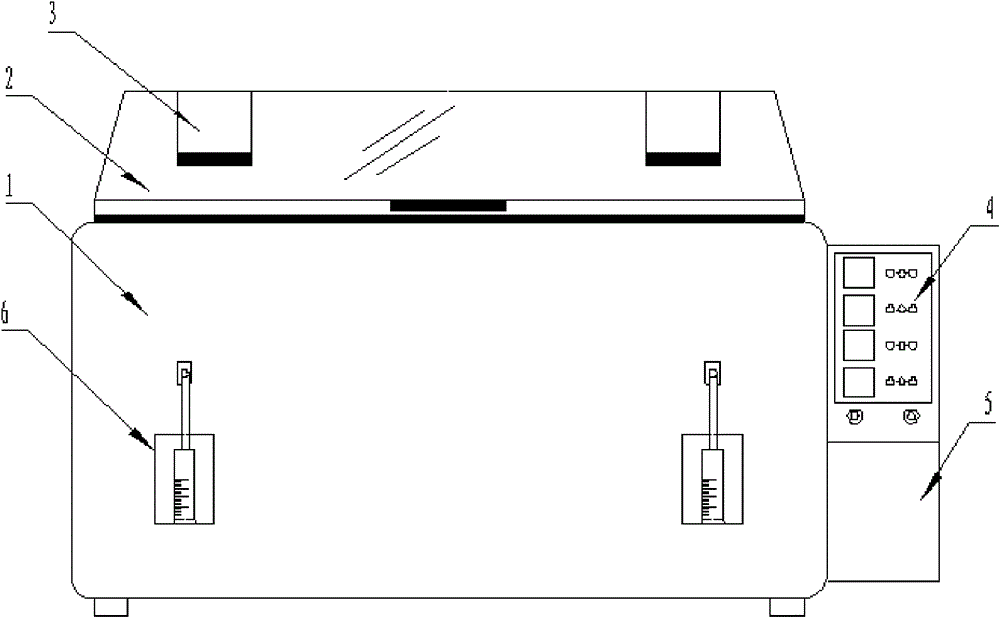

Multi-purpose salt fog test box

A salt spray test, multi-functional technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of large volume of salt spray box and single function of salt spray box, and achieve small size, simple structure and simplified equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

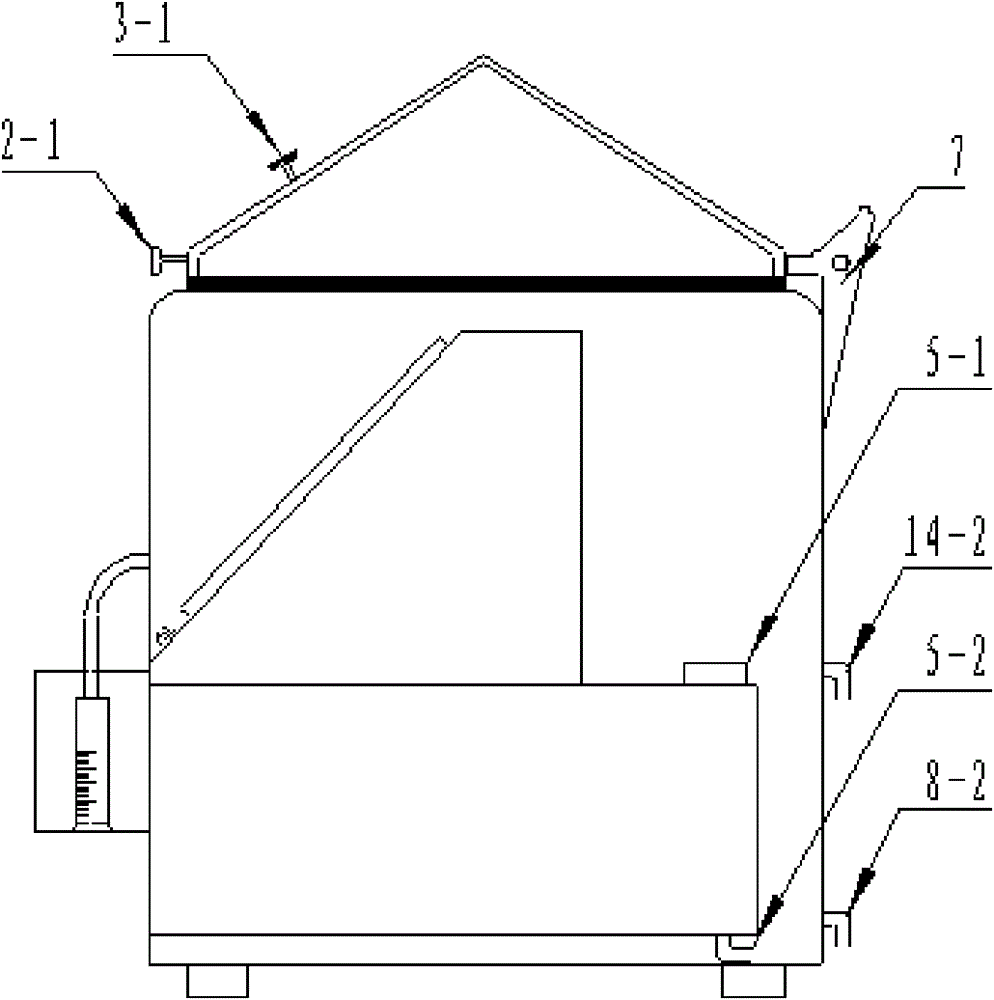

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Neutral salt spray test (GB10125-1997 "Artificial Atmosphere Corrosion Test Salt Spray Test")

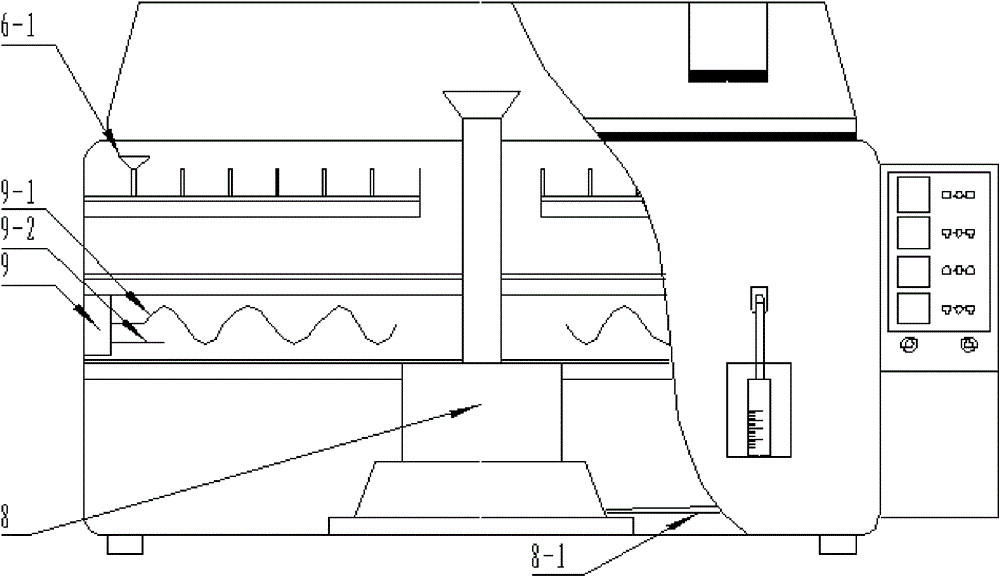

[0020] 1. configuration mass fraction is the sodium chloride solution of 5%, adds in the brine tank 5; Regulate the ultrasonic oscillation power on the control panel 4, after the salt spray tank runs 24 hours, make the measuring cylinder 6 outside the observation box collect every hour Saline volume reaches 1-2ml / 80cm 2 , pH 6.5-7.2.

[0021] 2. Put the sample to be tested on the card slot on the sample table set frame. If the sample is a large-size plate or part, you need to disassemble one or several belt slots, and add a special card slot baffle to make the large test sample in an appropriate location.

[0022] 3. Adjust the temperature button on the control panel 4 to keep the temperature in the exposed area of the salt spray box at 35°C.

[0023] 4. The test period should be selected according to the relevant standards of the tested material or product,...

Embodiment 2

[0025] Embodiment 2: constant temperature and humidity experiment

[0026] 1. Add deionized water into the water tank 5, replace the observation cover 3 with a special exhaust fan, and the fan is controlled by the control system.

[0027] 2. According to the needs of the test, set the humidity value and temperature value on the control panel 4.

[0028] 3. Put the sample to be tested on the card slot on the sample stage assembly frame. If the sample is a large-size plate or part, you need to remove one or several tape slots, and add a special The slot baffle keeps the large sample in a suitable position.

[0029] 4. The test period should be selected according to the relevant standards of the tested material or product.

[0030] 5. After the test, clean the main tank and the brine tank with clean water.

Embodiment 3

[0031] Embodiment 3: wet and dry alternate experiment

[0032] 1. Configure a sodium chloride solution with a mass fraction of 3.5%, and add it to the brine tank 5; add deionized water to the brine tank

[0033] 5, the observation cover 3 is replaced by a special exhaust fan.

[0034] 2. According to the needs of the test, set the periodic interrupt timer on the control panel 4. like simulating some kind of marine corrosion

[0035] Environment, dry environment and wet environment have a cycle of 12 hours, which can be set on the cycle interrupt timer

[0036] Room, humidity and temperature values; for example, the humidity of the humid environment is 80%, the temperature is 25°C, and the time is 12 hours, while the dry environment

[0037] The drying environment is 5% humidity, 40°C, and 12 hours.

[0038] 3. Put the sample to be tested on the card slot on the sample stage assembly frame. If the sample is a large-size plate or part, it needs to be disassembled

[0039]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com