Method for controlling rotation eccentricity mass and load during wind turbine blade fatigue test

A wind turbine blade and fatigue test technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problem of difficulty in estimating the size of the rotating mass, the inability to ensure the consistency of the load range of wind turbine blades, and blade fatigue. The load is difficult to control and other problems, to achieve the effect of ensuring accuracy and scientificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with specific embodiment and accompanying drawing,

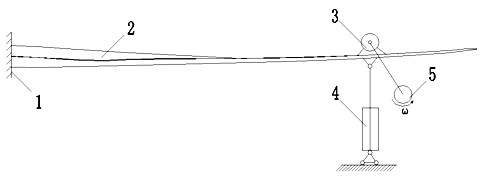

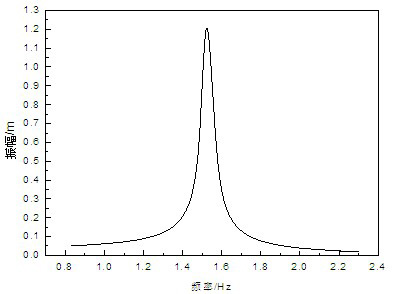

[0009] attached figure 1 The principle of a rotating eccentric mass to the wind turbine blade fatigue loading device is given. It can be seen from the accompanying drawings that the present invention is a method for controlling the rotating eccentric mass and load of the wind turbine blade fatigue test, and the blade is measured by the free vibration method. Natural frequency and damping, by calculating or measuring the static displacement of the wind turbine blades under the design fatigue load, and using this displacement value as the fatigue vibration amplitude of the blades to predict the size of the rotating eccentric mass of the fatigue load applied to the blades, through a certain method The load control is converted into equivalent displacement change control, and the displacement sensor is used to monitor the displacement of the loading posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com