Seaming method of underground diaphragm wall

An underground continuous wall and hinged pipe technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problem of difficult cleaning of slag or local mud, uneven force on the cleaning surface, and bulky steel cages, etc. To solve the problem of cleaning and brushing, ensure the effect of brushing mud, and achieve the effect of simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

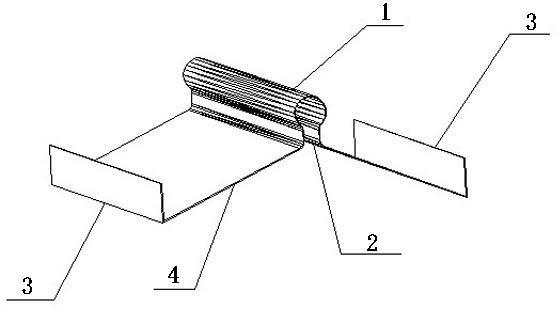

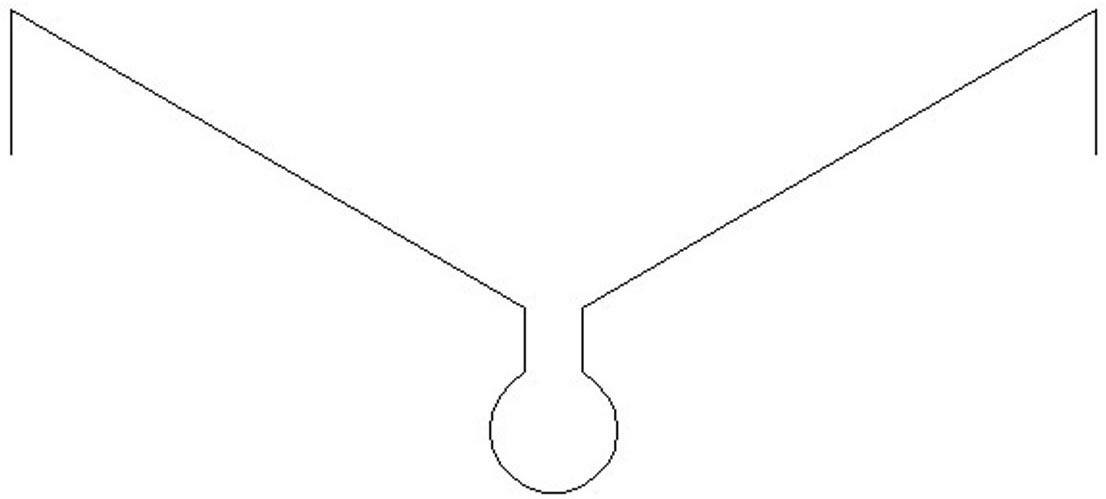

[0019] like Figure 1-5 As shown, the total reference numerals 1-15 represent respectively: hinged pipe 1, hinged pipe opening 2, hemming part 3, wing plate 4, guide wall 5, reinforced cage for pouring concrete 6, drawing rubber 7, lock pipe 8. Articulated joint 9, water stop plate 10, guide roller 11, V-shaped wall brush 12, wire brush 13, rectangular box 14, V-shaped frame 15.

[0020] like Figure 1-2 As shown, the hinged joint 9 of the underground diaphragm wall involved in this embodiment is composed of a hinged tube 1, a hemming part 3, and a wing plate 4. The end face of the hinged tube 1 is approximately Ω-shaped, with a partial opening. The two ends of each are respectively connected to the wing plate 4, and the outer ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com