Double-pipe sinking construction method and heating pipeline system

A construction method and immersed pipe technology, applied in the direction of pipes/pipe joints/pipes, pipe laying and maintenance, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

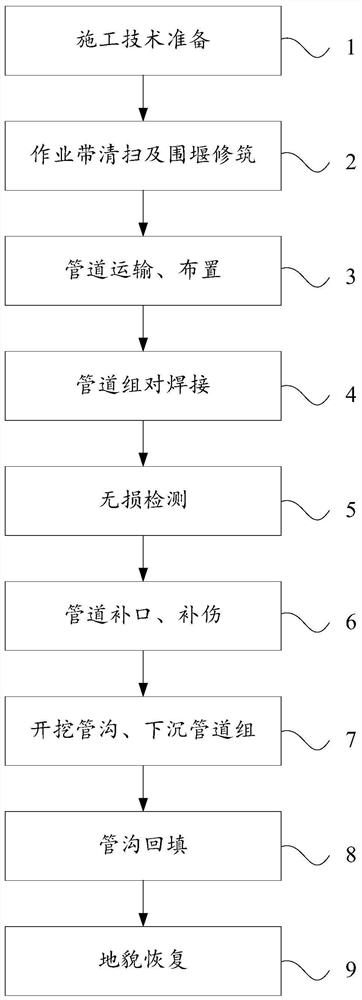

[0038] see Figure 1 to Figure 3 As shown, the double-pipe immersed pipe construction method provided by the application includes the following steps:

[0039] Step 1: Construction technical preparation;

[0040] Step 2: cleaning of work belt and construction of cofferdam;

[0041] Step 3: pipeline transportation and layout;

[0042] Step 4: pipe group butt welding;

[0043] Step 5: Non-destructive testing;

[0044] Step 6: Repair the mouth and damage of the pipeline;

[0045] Step 7: Excavating pipe trenches and sinking pipe groups;

[0046] Step 8: Backfilling the pipe trench;

[0047] Step 9: Landform Restoration.

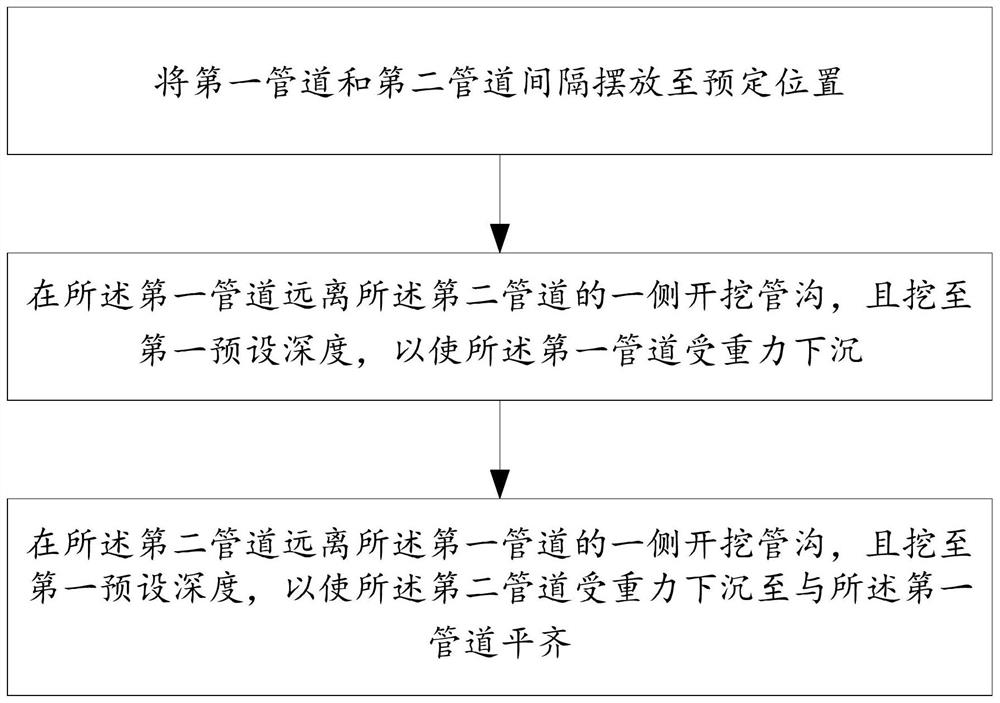

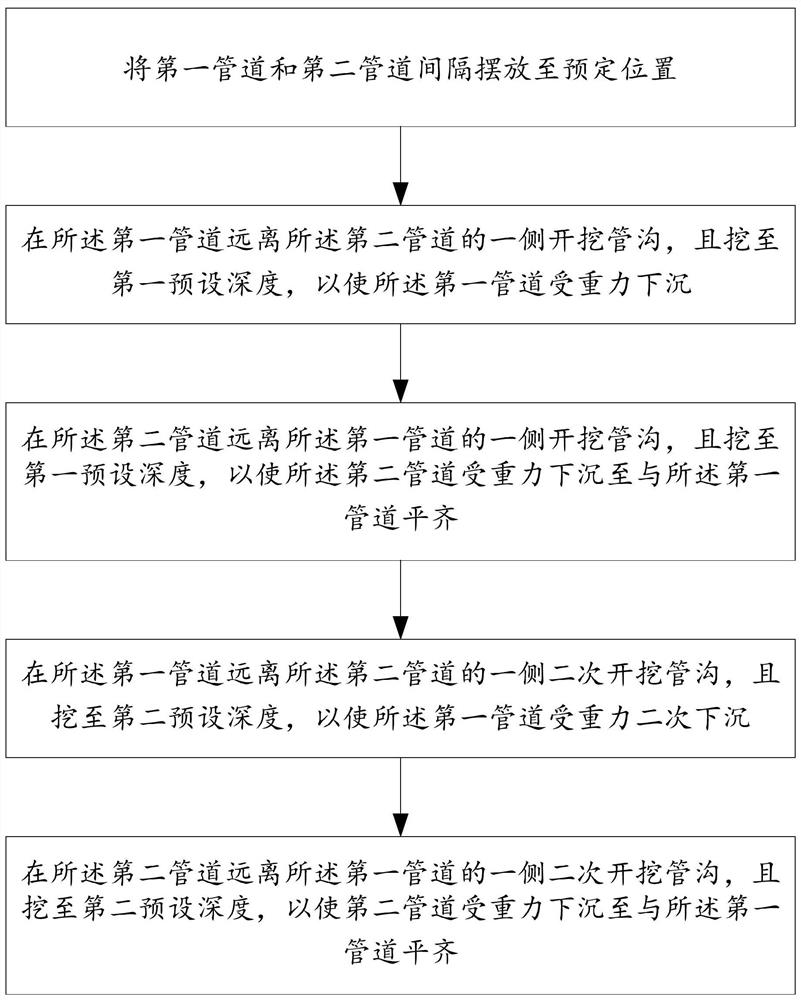

[0048] Among them, in the steps of excavating pipe trenches and sinking pipe groups, it is different from the step of excavating and laying on both sides of the pipe at the same time in the construction of single-pipe immersed pipes. Excavate the immersed pipe on one side, then repeat the above operation for the other pipe. If double-pipe immersed pipe ...

Embodiment 2

[0061] The double-tube immersed pipe construction method in the second embodiment is an improvement on the basis of the above-mentioned embodiment. The technical content disclosed in the above-mentioned embodiment will not be described repeatedly, and the content disclosed in the above-mentioned embodiment also belongs to the content disclosed in the second embodiment. .

[0062] In the optional solution of this embodiment, when the distance between the first pipe and the second pipe is not allowed to deviate, it is necessary to use pipe clips to fix the first pipe and the second pipe. And the pipe clamp can adjust the distance between the first pipe and the second pipe so that the distance can meet the requirement. Specifically, the distance between the closest points on the outer surfaces of the first pipe and the second pipe arranged side by side is 500mm.

[0063] In the optional scheme of this embodiment, in step 4, the assembly of pipelines is carried out in strict acco...

Embodiment 3

[0082] Embodiment 3 of the present application provides a heating pipeline system, which is obtained by adopting the double-pipe immersed pipe construction method of any one of the above-mentioned embodiments, and can meet the requirement of double-pipe circulation of water supply and return water in heating projects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal diameter | aaaaa | aaaaa |

| Nominal diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com