Preparation method of impregnated paper for decorative surface on high-glossiness furniture

A technology of impregnated paper and high gloss, applied in the field of decorative paper, can solve the problems of high cost and complicated process, and achieve the effect of high gloss, simple process and increased scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

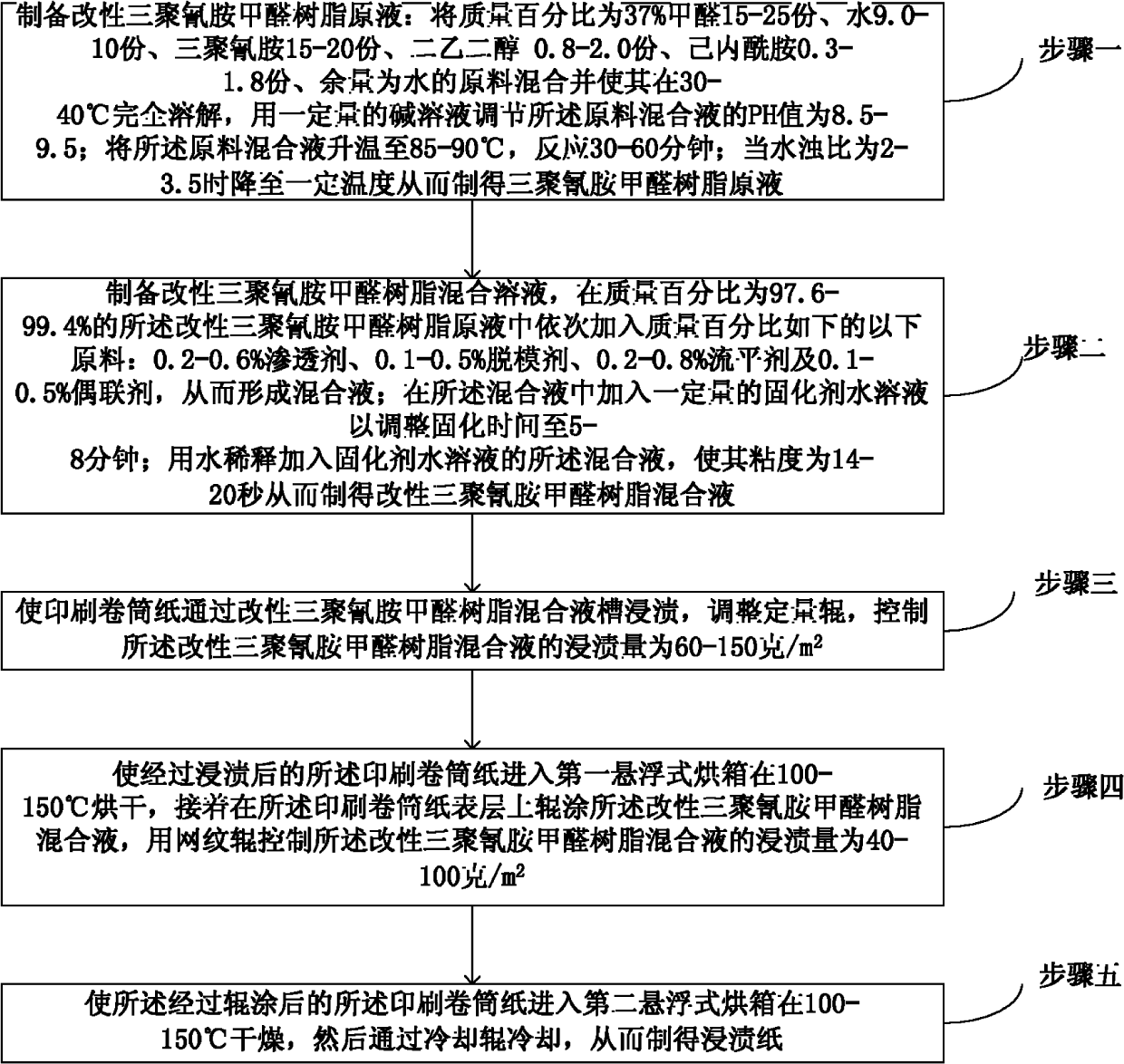

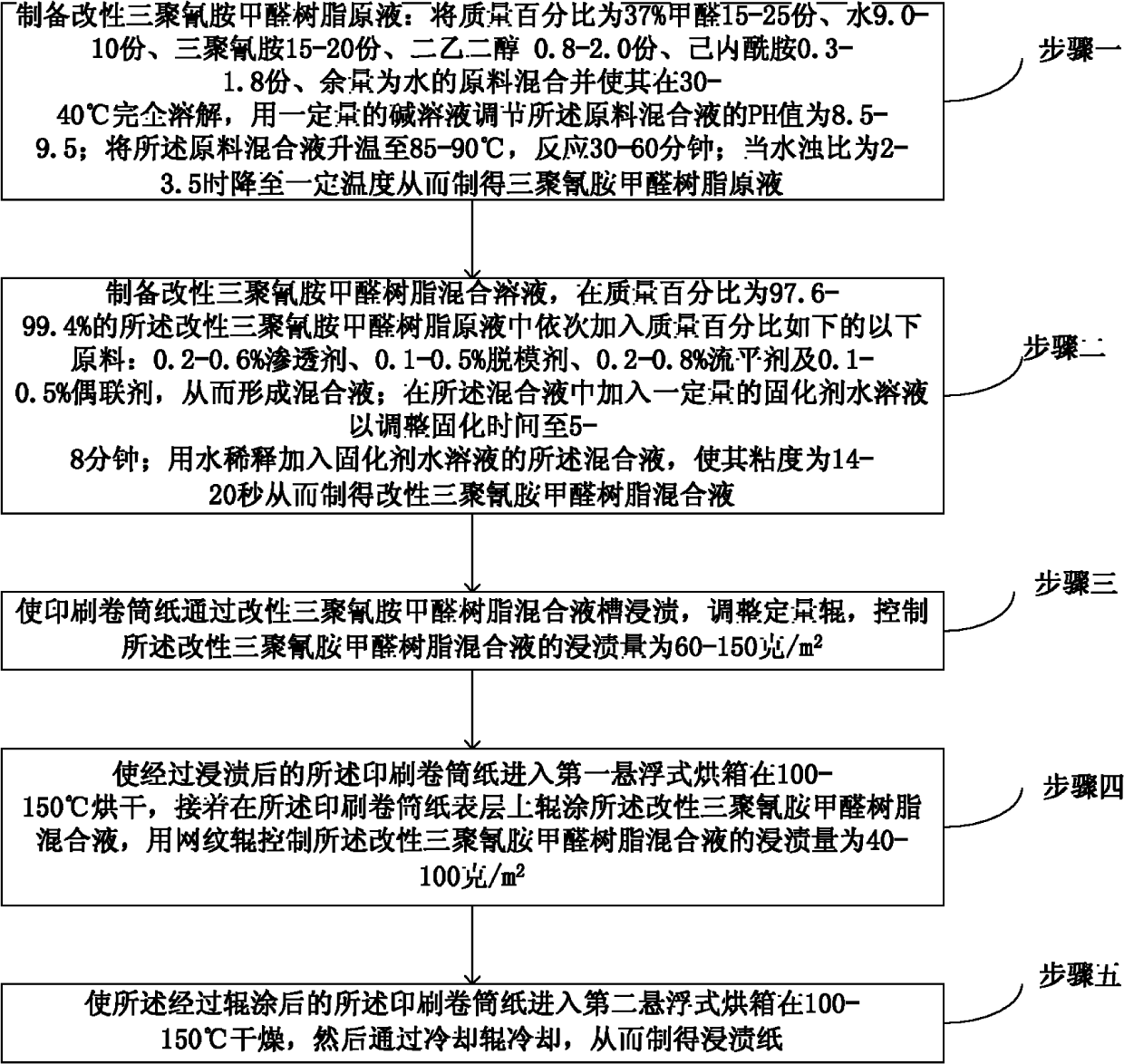

Method used

Image

Examples

Example Embodiment

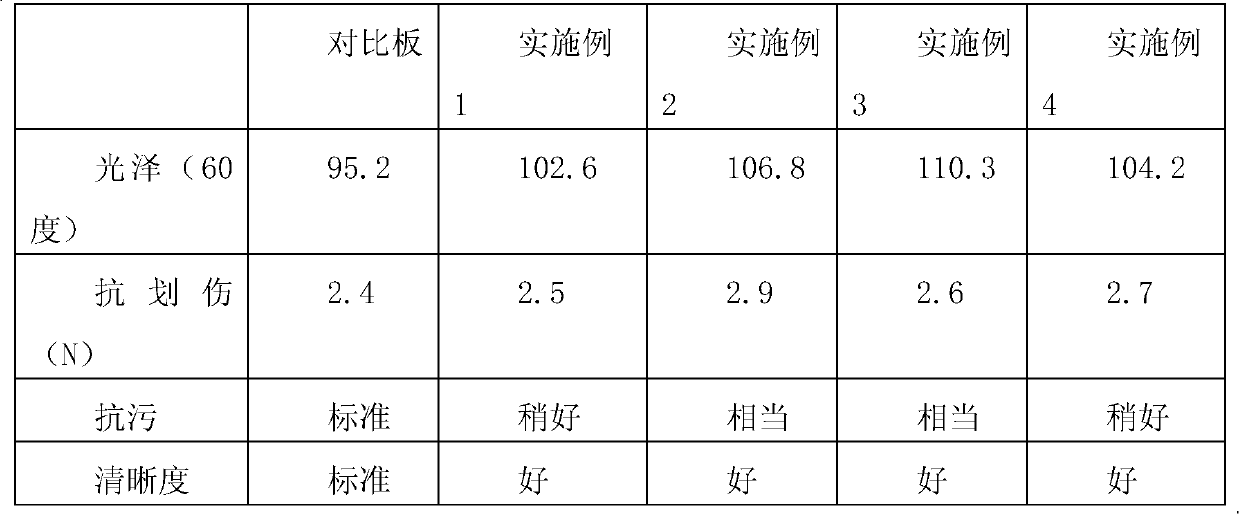

[0025] Example 1

[0026] Preparation of modified melamine formaldehyde resin stock solution: the raw materials are proportioned by the following parts by weight: 21 parts of formaldehyde aqueous solution with 37% formaldehyde mass percentage, 18 parts of melamine, 1.2 parts of diethylene glycol, 1.5 parts of caprolactam, and the balance is water; The raw materials are mixed and completely dissolved at 33°C to obtain a raw material mixture; the pH value of the raw material mixture is adjusted to 9.0 with a 20% NaOH solution; the raw material mixture is heated to 87°C and reacted for 60 minutes; The water turbidity ratio was measured, and when the water turbidity ratio was 2.1, the temperature was lowered to below 35°C, and the material was discharged to obtain the melamine formaldehyde resin stock solution.

[0027] Prepare modified melamine-formaldehyde resin mixture: weigh the raw materials, and the raw materials are proportioned according to the following weight percentages: 98....

Example Embodiment

[0032] Example 2

[0033] Prepare modified melamine formaldehyde resin stock solution: the raw materials are proportioned as follows: 23 parts of formaldehyde aqueous solution with 37% formaldehyde mass percentage, 20 parts of melamine, 1.4 parts of diethylene glycol, 1.0 part of caprolactam, and the balance of water; The raw materials are mixed and completely dissolved at 35°C to obtain a raw material mixture; the pH value of the raw material mixture is adjusted to 9.1 with a 20% NaOH solution; the raw material mixture is heated to 88°C and reacted for 55 minutes; The water turbidity ratio was measured, and when the water turbidity ratio was 2.3, the temperature was lowered to below 35°C, and the material was discharged, thereby preparing the melamine formaldehyde resin stock solution.

[0034] Prepare the modified melamine-formaldehyde resin mixture, weigh the raw materials, and the raw materials are proportioned according to the following weight percentages: 98.6% of the modifie...

Example Embodiment

[0039] Example 3

[0040] Preparation of modified melamine formaldehyde resin stock solution: the raw materials are proportioned by the following parts by weight: 24 parts of formaldehyde aqueous solution with a formaldehyde mass percentage of 37%, 15 parts of melamine, 1.4 parts of diethylene glycol, 1.4 parts of caprolactam, and the balance being water; The raw materials are mixed and completely dissolved at 35°C to obtain a raw material mixture; the pH value of the raw material mixture is adjusted to 9.3 with a 20% NaOH solution; the raw material mixture is heated to 88°C and reacted for 50 minutes; The water turbidity ratio is measured, and when the water turbidity ratio is 2.5, the temperature is lowered to below 35°C, and the material is discharged, thereby preparing the melamine formaldehyde resin stock solution.

[0041] Prepare modified melamine-formaldehyde resin mixture: weigh the raw materials, and the raw materials are proportioned according to the following weight per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com