Composite flooding system containing lipopeptide biological surfactant and application thereof

A bio-surface, composite flooding technology, applied in the fields of fluid production, drilling composition, wellbore/well components, etc., can solve problems such as affecting large-scale applications, difficult field application control, and reducing polymer viscoelasticity. , to achieve the effect of promoting large-scale industrial application, easy control and application, and strengthening interface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Preparation of lipopeptide biosurfactant:

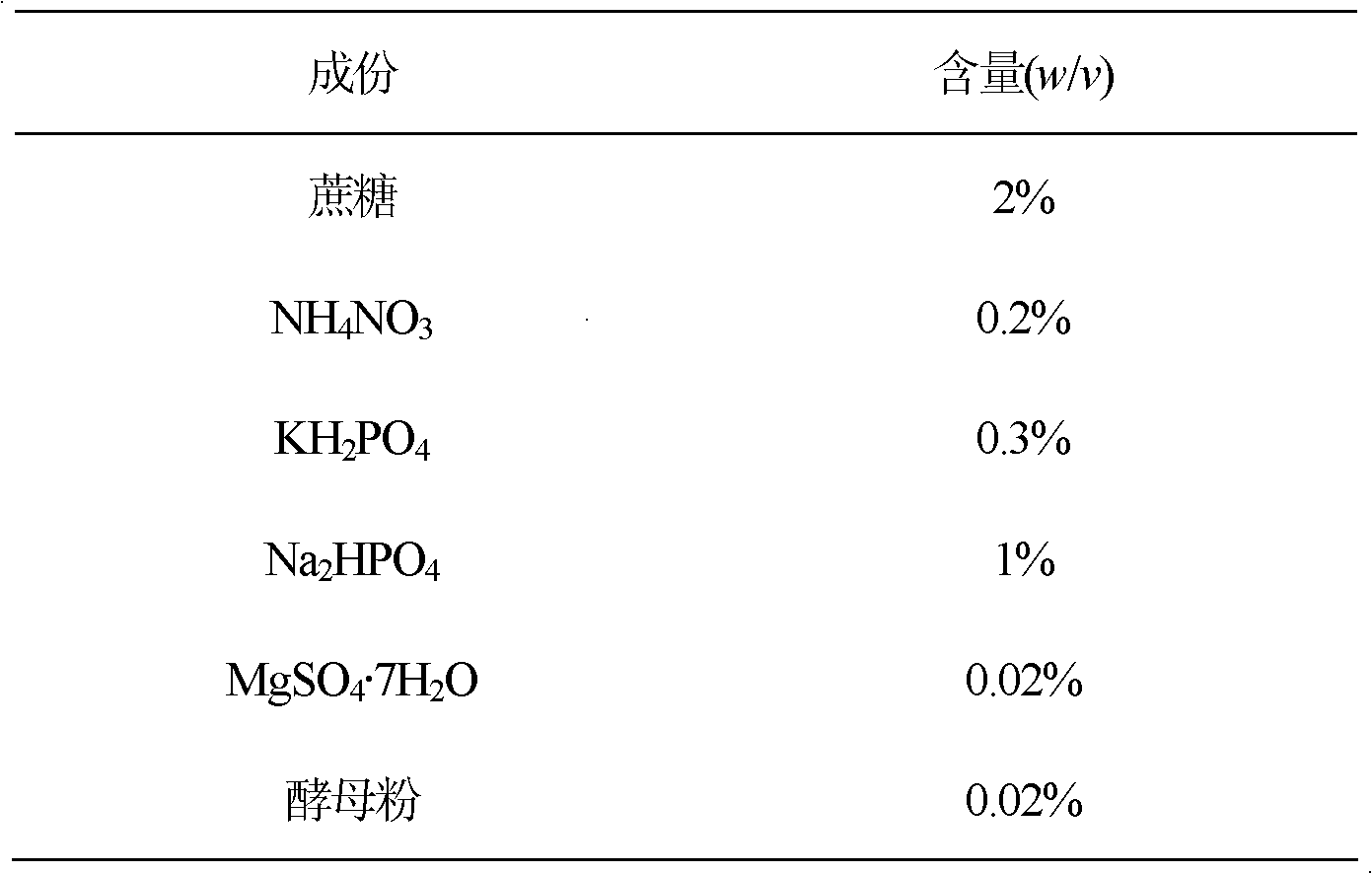

[0025] The lipopeptide biosurfactant is produced by culture and fermentation of Bacillus subtilis (preservation number CGMCC1.1470) at 30°C. The culture medium was prepared with clean water, and its composition is shown in Table 1.

[0026] Table 1 prepares the medium composition of lipopeptide biosurfactant

[0027]

[0028] The lipopeptide biosurfactant content in the fermentation broth is 80-150mg / L.

Embodiment 1

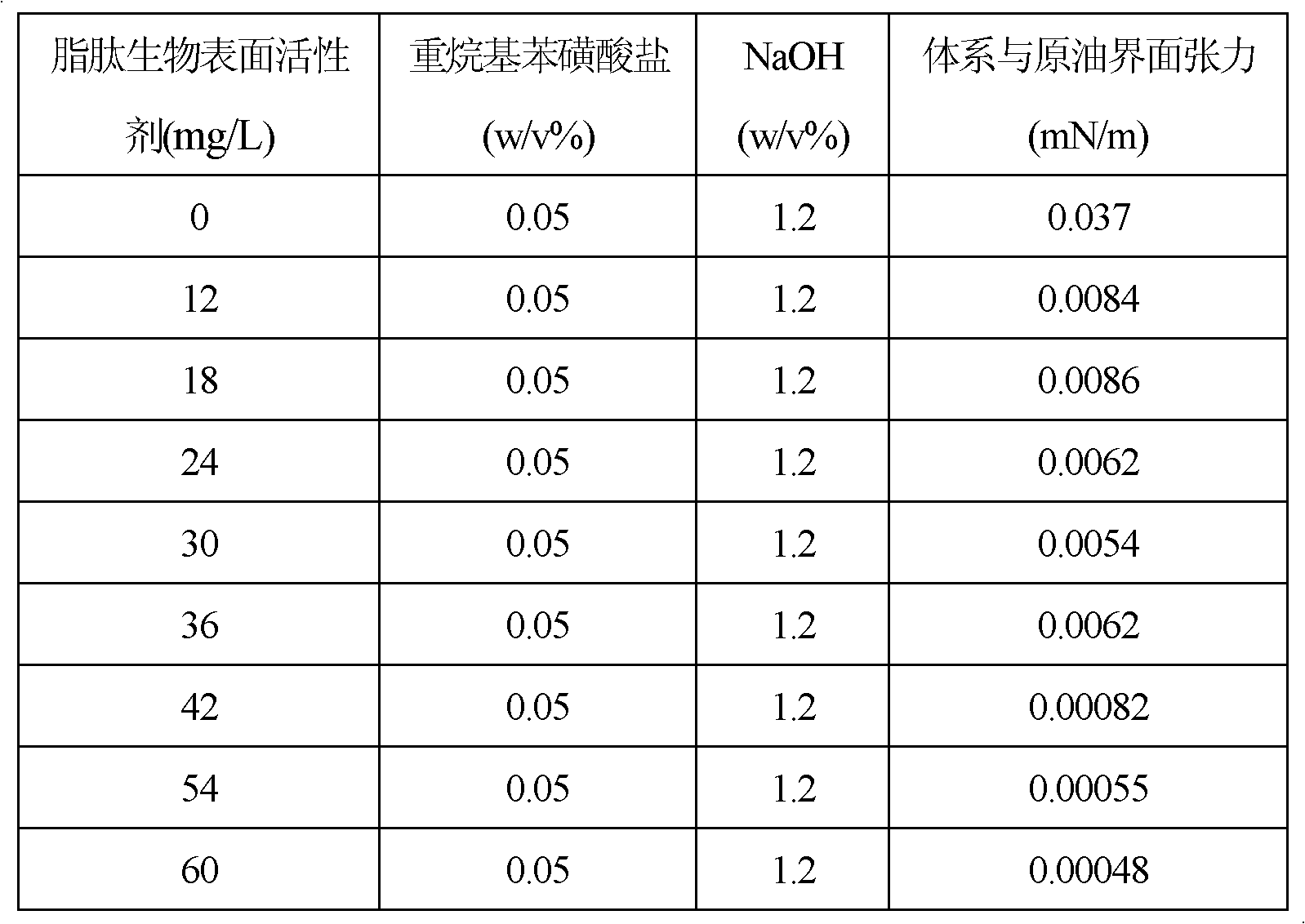

[0029] Example 1 Composite oil displacement system under different lipopeptide biosurfactant concentrations

[0030] Lipopeptide biosurfactant: 0, 12~60mg / L

[0031] Heavy alkylbenzene sulfonate: 0.05%, w / v%

[0032] NaOH: 1.2%, w / v%

[0033] Prepare with water.

[0034] As can be seen from Table 2, under the conditions of NaOH: 1.2% (w / v%), heavy alkylbenzenesulfonate 0.05% (w / v%), the existing system (lipopeptide biosurfactant concentration is 0mg / L, NaOH: 1.2%w / v%, heavy alkyl benzene sulfonate 0.05w / v%) and crude oil interfacial tension is 0.037mN / m; add 12~60mg / L lipopeptide biosurfactant The inventive system can further reduce the interfacial tension and reach the ultra-low interfacial tension (10 -3 mN / m), the interfacial tension between the composite flooding system and crude oil with the best interfacial activity can even reach 10 ~4 mN / m, which is 2 orders of magnitude lower than that without lipopeptide biosurfactant.

[0035] Table 2 Interfacial activity of ...

Embodiment 2

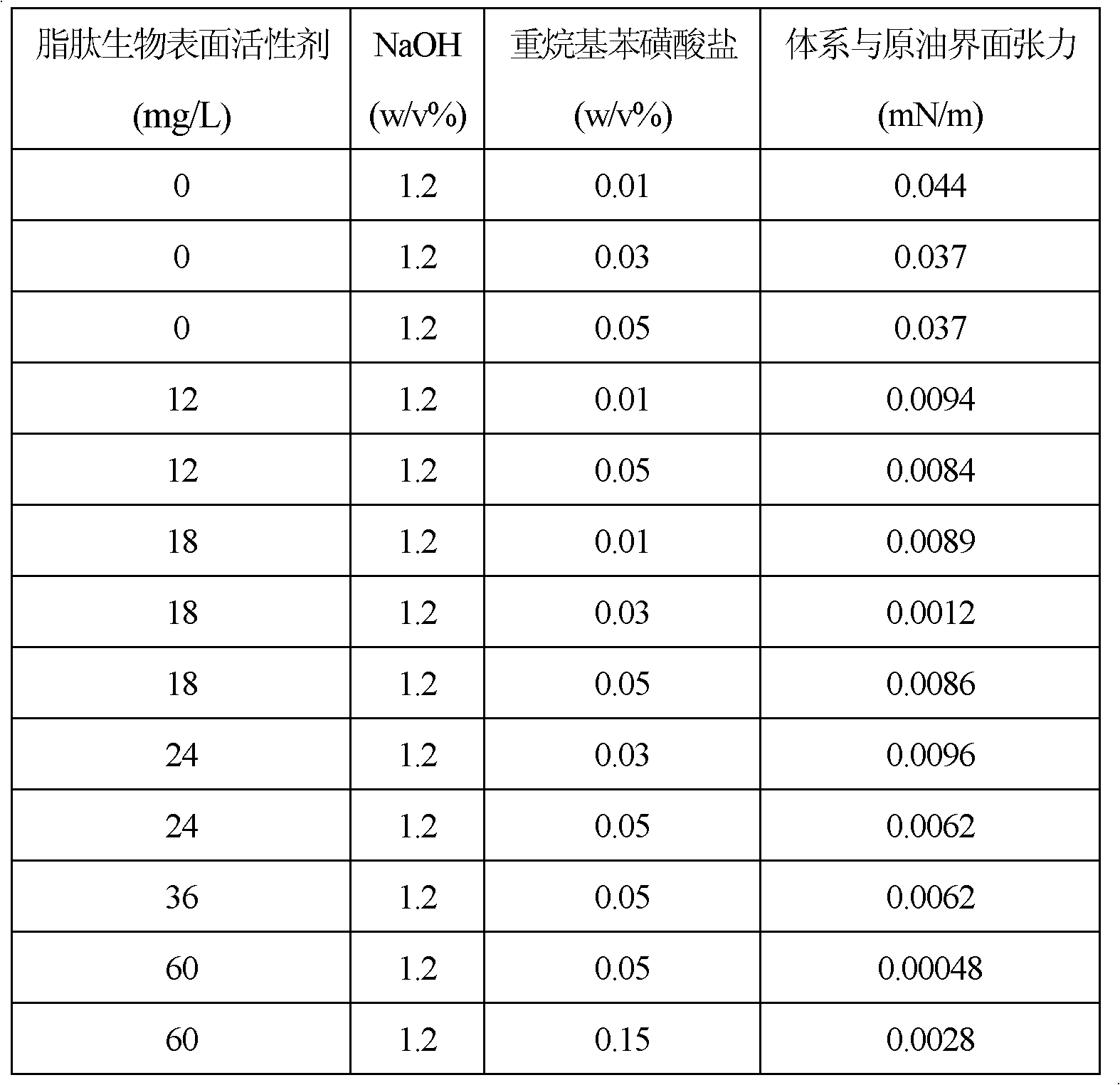

[0037] Example 2 Interfacial activity of different composite flooding systems

[0038] Lipopeptide biosurfactant: 0, 12~60mg / L

[0039] Heavy alkylbenzene sulfonate: 0.01~0.15, w / v%

[0040] NaOH: 1.2, w / v%

[0041] Formation water preparation

[0042] As can be seen from Table 3, the existing lipopeptide biosurfactant concentration of 0 mg / L, NaOH 1.2w / v%, and heavy alkylbenzene sulfonate concentrations of 0.01, 0.03, and 0.05w / v% respectively The interfacial tension between the system and crude oil is 0.044, 0.037, 0.037mN / m respectively; the system of the present invention (containing lipopeptide biosurfactant) can further reduce the interfacial tension, and only a small amount of lipopeptide biosurfactant, heavy alkyl benzene sulfonate The ultra-low interfacial tension (10 -3 mN / m), and when the heavy alkylbenzene sulfonate concentration is 0.05%, the interfacial tension can be stabilized at 10 ~3 mN / m. However, to achieve the same interfacial tension value using the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com