Method for preparing high-strength epoxy resin adhesive

A technology of epoxy resin and epoxy group, applied in the direction of epoxy resin glue, adhesive type, adhesive, etc., can solve the problems of degumming, strength reduction and dimensional instability of glued joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the accompanying drawings.

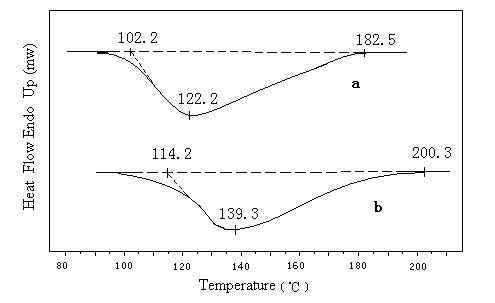

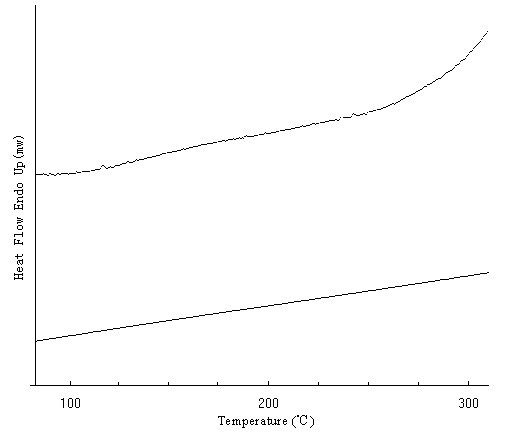

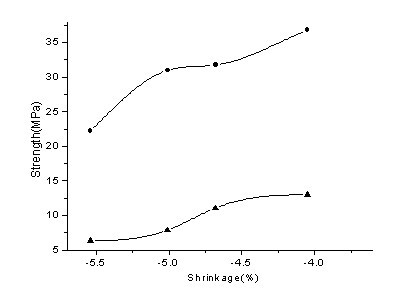

[0016] The curing reaction of modified epoxy resin is a complex reaction system. It can be seen from the exothermic curve and infrared spectrum that the spiro ring group disappears and the epoxy conversion rate increases. It is inferred that the epoxy resin and the prepolymer have a copolymerization reaction. Mix prepolymers with different weight ratios (synthetic molar ratios are 2:1, 3:2, 4:3) and epoxy resin in a small beaker at room temperature, and add 3% boron trifluoride by weight of the mixed resin Stir the ethylamine curing agent evenly, mix the small beaker containing the mixture in an ultrasonic cleaner for 1 hour, and then put it in a vacuum oven to debubble for 2 hours. The polymerization reactivity of the epoxy group is greater than that of the spiro group, that is, the epoxy group can undergo ring-opening reaction at low temperature, while the ring-open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com