Natural bamboo fiber optical intelligent composite material and preparation method thereof

A natural bamboo fiber and optical fiber intelligent technology, which is applied in building materials, chemical instruments and methods, and the measurement of the change force of optical properties of materials when they are stressed, can solve complex processing processes, environmental pollution, and energy consumption. Advanced problems, to achieve the effect of high sensitivity, low cost, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

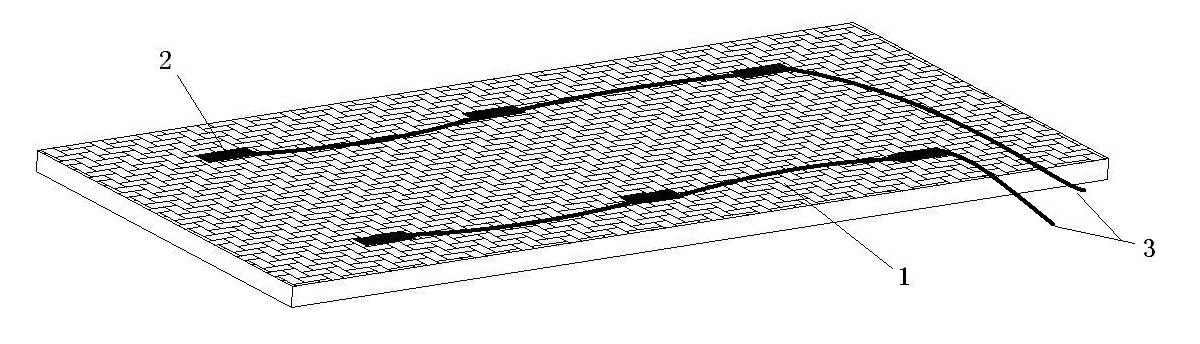

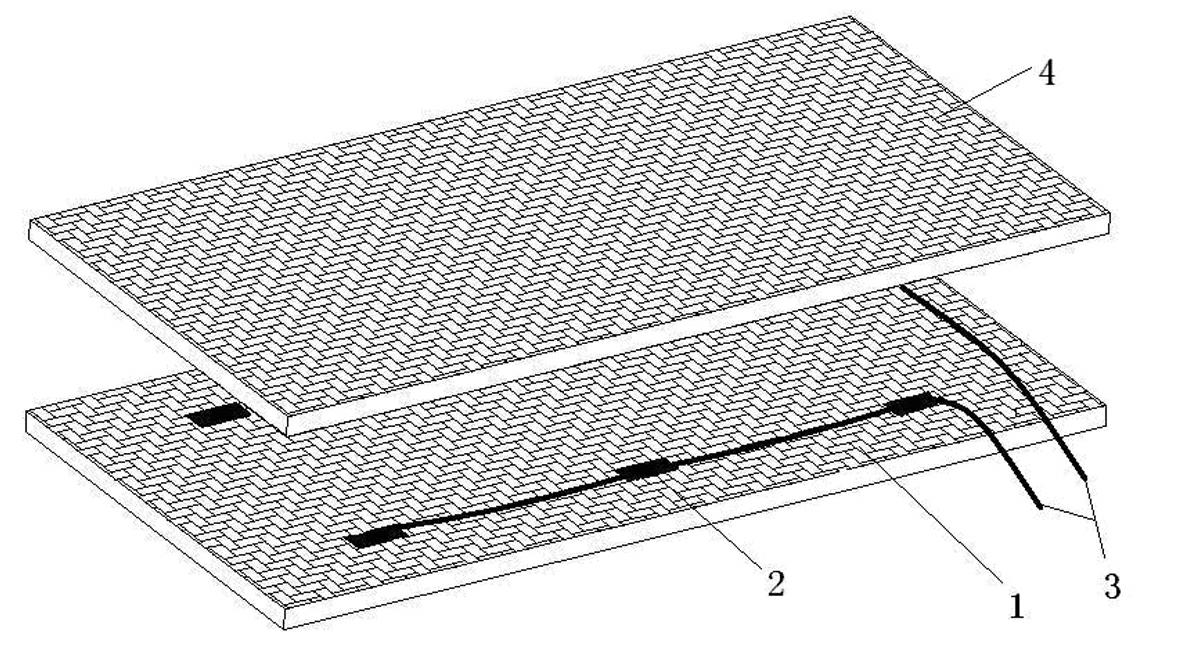

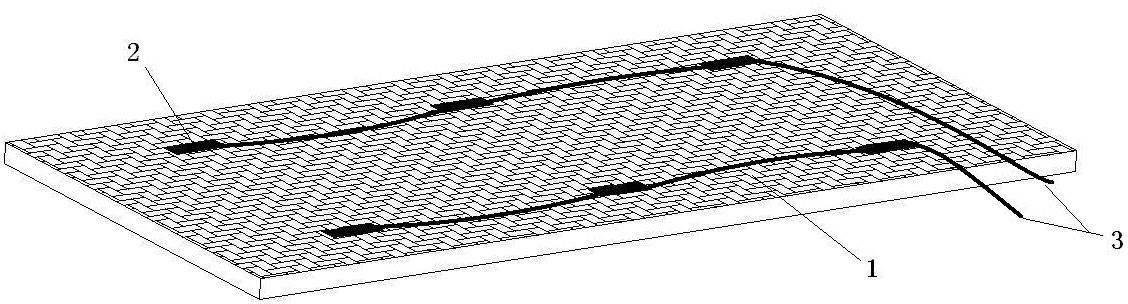

[0025] With reference to the accompanying drawings, the embodiment of the natural bamboo fiber optical fiber intelligent composite material is composed of a bamboo glued strip bottom layer 1, an optical fiber strain sensor 2, and a bamboo glued strip surface layer 4. The optical fiber strain sensor 2 is provided with a sensing wire 3, and the optical fiber strain sensor 2 is located at Between the bottom layer 1 of the bamboo glued strip and the surface layer 4 of the bamboo glued strip, the sensing wire 3 extends beyond the edge of the bottom layer 1 of the bamboo glued strip and the surface layer 4 of the bamboo glued strip.

[0026] Preparation:

[0027] (1) According to the design requirements, several layers of natural bamboo strip fiber layers are glued and pressed into a glued bamboo strip layer with a specified thickness, which is used as the bottom layer of bamboo glued strip 1;

[0028] (2) Select the type of embedded optical fiber strain sensor 2 according to the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com