Six-freedom-degree parallel steel belt robot mechanism with roller device

A degree of freedom, robot technology, used in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problem of limited application of parallel robots, and achieve the effects of simple structure, simple control, and increased compression stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

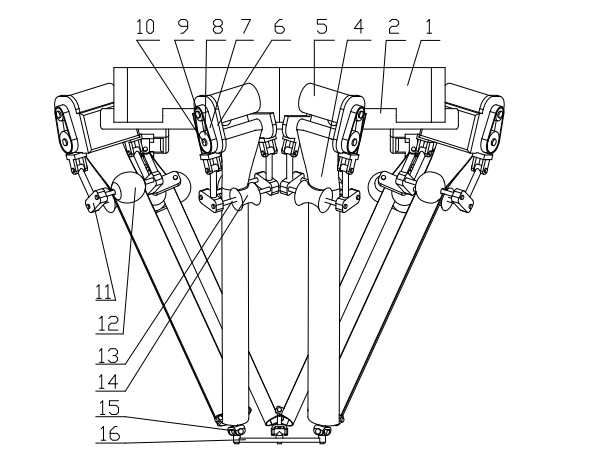

[0026] refer to Figure 1-3 , a six-degree-of-freedom steel belt parallel robot mechanism with a roller device, including a frame, the frame includes a base 1, and three crossbars 2 are installed on the base 1, and the two ends of the crossbar 2 are connected with kinematic supports chain, the motion branch chain includes a motor base 6 connected to the cross bar 2, a servo motor 5 is installed on the inner side of the end cover of the motor base 6, and a first pulley 9 is connected to the rotor of the servo motor 5, so The motor base 6 is hinged with a reel 10, and one end of the reel 10 extending out of the motor base 6 is connected with a second pulley 8, and the first pulley 9 and the second pulley 8 are connected by a belt 7, and the reel 10 There is a steel belt 4 that can rotate around it, the lower end of the steel belt 4 is hinged with a compound ball joint 15, and the compound ball joint 15 is hinged to the moving platform 16; the upper end of the steel belt 4 is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com