Multifunctional arc welding vision monitoring device and monitoring method

A monitoring device and multi-functional technology, applied in the direction of arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of increased number of equipment, high cost, high multiple target areas, etc., and achieve simple and easy operation, simple and compact structure , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

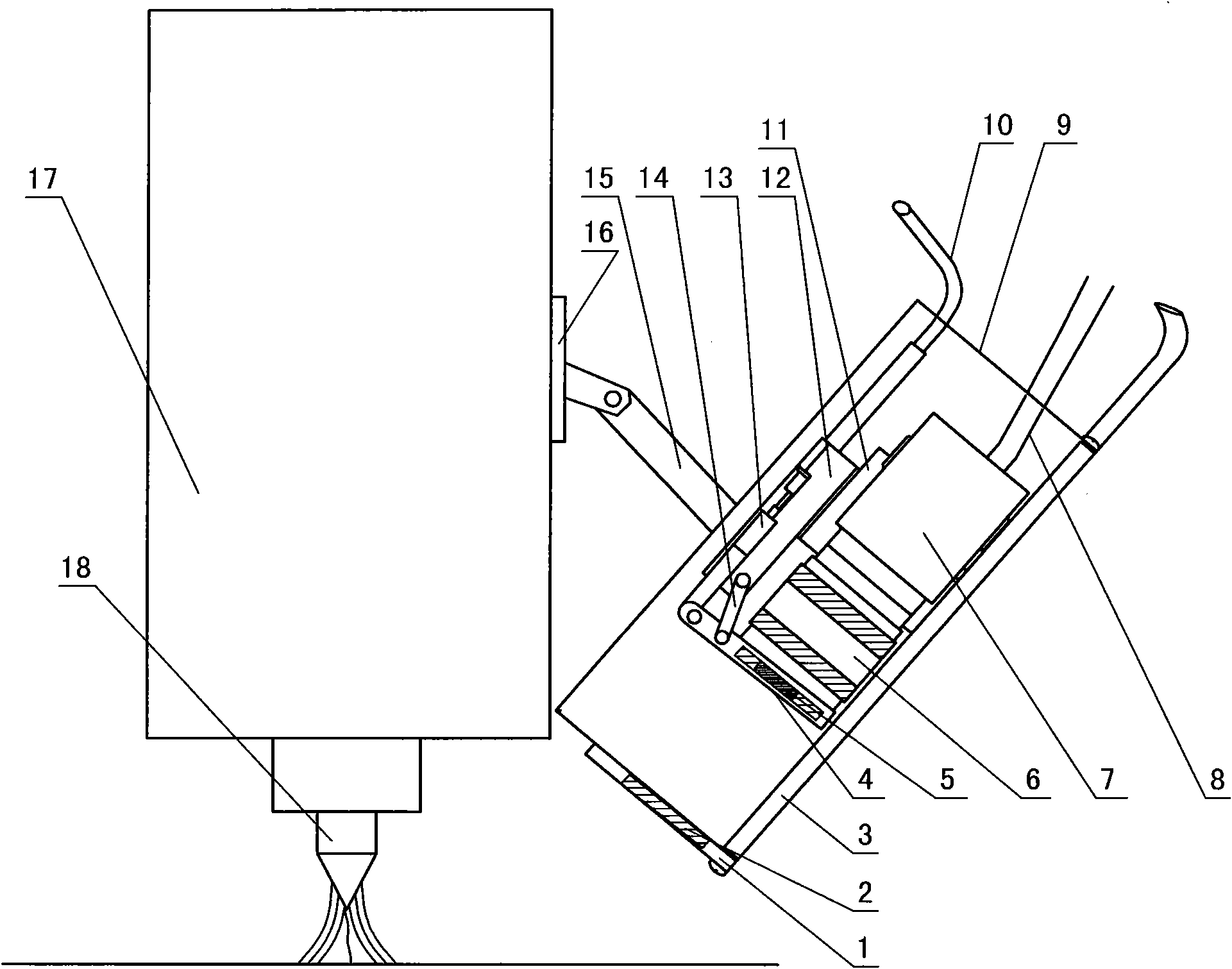

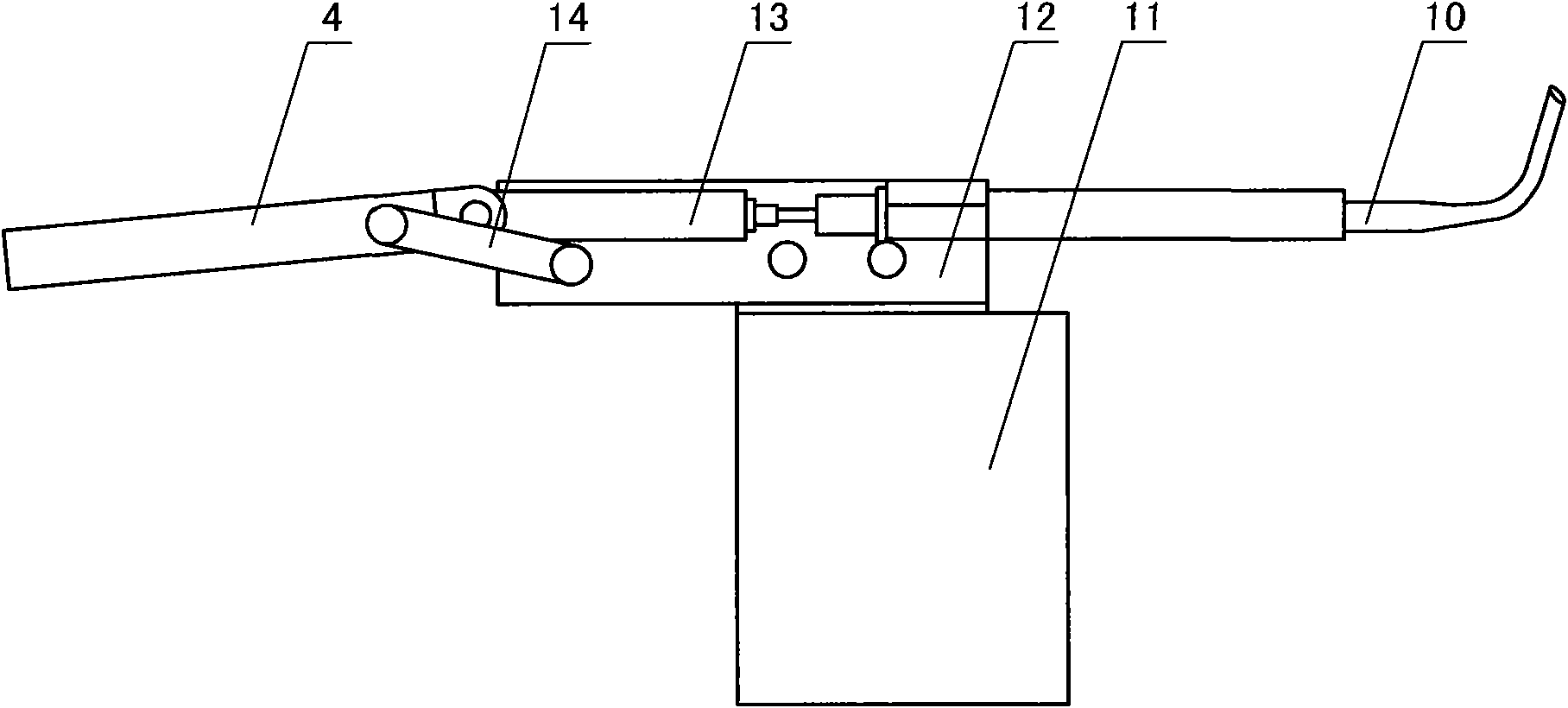

[0019] See attached Figure 1-4 , The device and method disclosed in the present invention are suitable for visual sensing monitoring in welding or cutting processes such as argon tungsten arc welding, gas metal arc welding, laser welding, and plasma arc welding.

[0020] This multifunctional arc welding visual monitoring device comprises a housing 9 of the monitoring device, a camera 7, a lens 6 and an optical filter 5 are housed in the housing 9, the lens 6 is installed at the end of the camera 7, and the video line 8 of the camera 7 It extends out of the housing 9 and is connected to an external monitor. It also includes a pneumatic linkage device installed in the housing 9. The camera adopts a CCD camera or other cameras with a lens that can adjust the aperture, wherein:

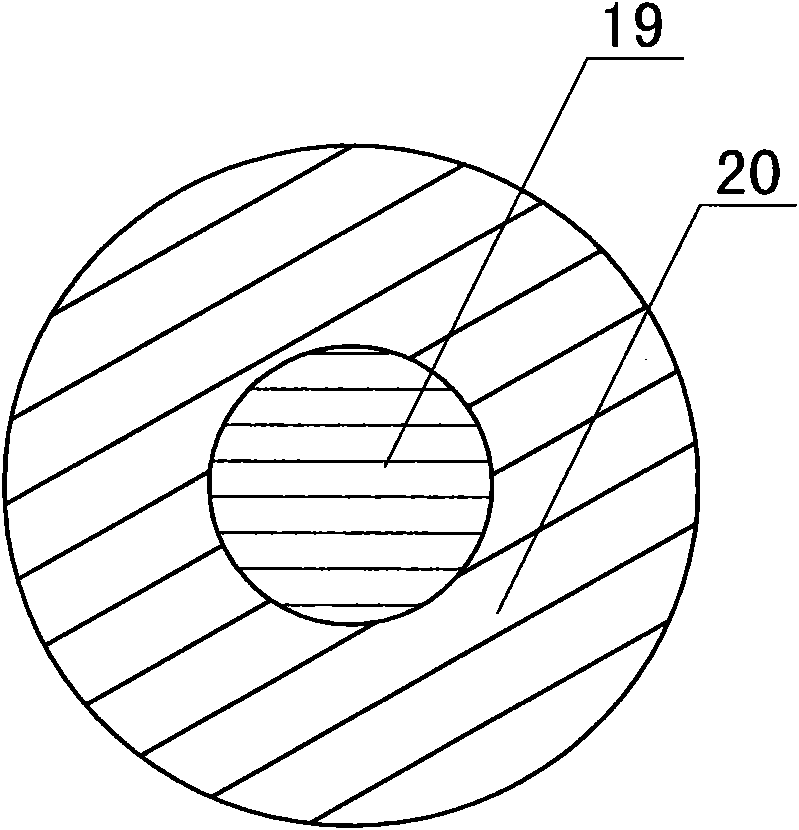

[0021] A cooling pipe 3 communicating with the outside is installed on the inner side wall of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com