Method for overlaying cone by cobalt-chromium-tungsten hard alloy

A hard alloy, cobalt chromium tungsten technology, applied in the field of surfacing, can solve the problems of poor heating of the cone and inability to adjust the welding position of the cone, etc., and achieve the effects of stable technical performance, wide application and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

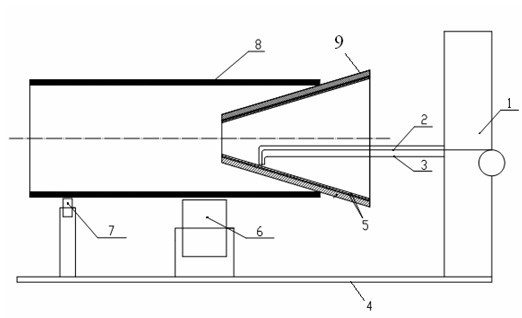

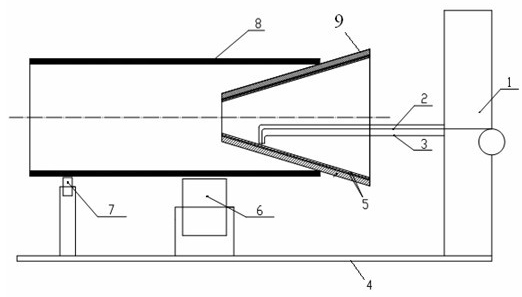

[0013] Such as figure 1 As shown, the present invention is achieved in this way, and the method steps are: the tip of the cone 9 extends into the cylinder 8, the side wall of the cone 9 is fixed on the end of the cylinder 8 by spot welding, and the bottom of the cylinder 8 The front and rear ends of the tube are respectively connected to the roller 7 and the adjustable roller frame 6 in turn. The roller 7 is connected to the small tube inner wall surfacing welding machine base 1 through the base 4, and the side wall of the small tube inner wall surfacing welding machine base 1 is connected to the small tube surfacing welding torch 3, and the small tube surfacing welding gun 3 is connected to the small tube surfacing welding gun 3. The welding torch 3 extends into the cone 9, and a small tube surfacing welding torch 3 is used to surfacing the cone 9. The welding wire of the surfacing 2 is ER309MoL and a 3mm surface layer (ER316L), the specification is φ1.6mm, and the surfacing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com