Air hole drilling device

A technology of air hole and drilling mechanism, which is applied in the field of foundry machinery, can solve the problems of poor discharge of exhaust gas, failure of exhaust gas to be discharged, poor ventilation of sand tires, etc., to achieve simple and easy-to-understand structural principles, save manpower, Achieve the effect of mechanical integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

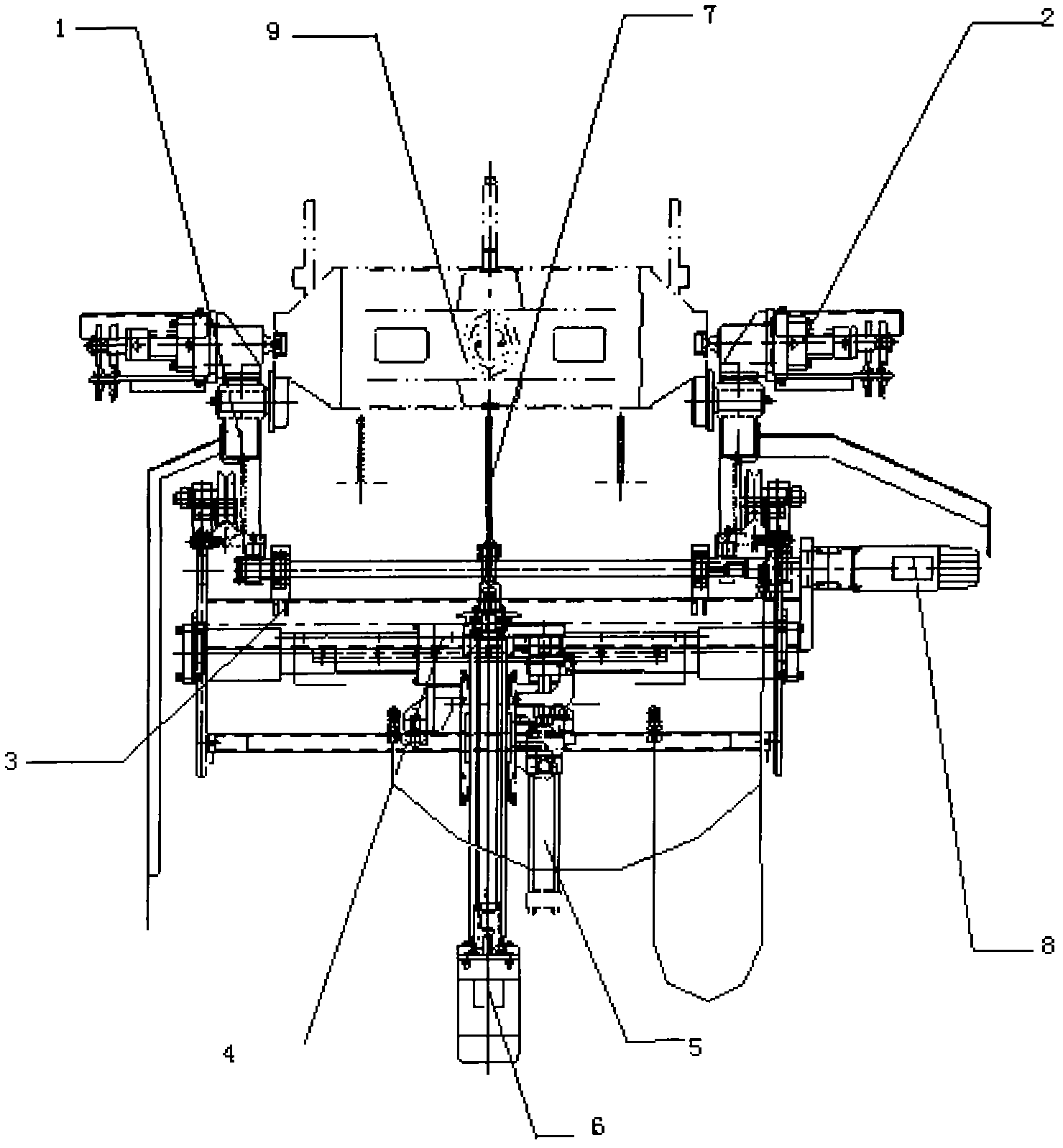

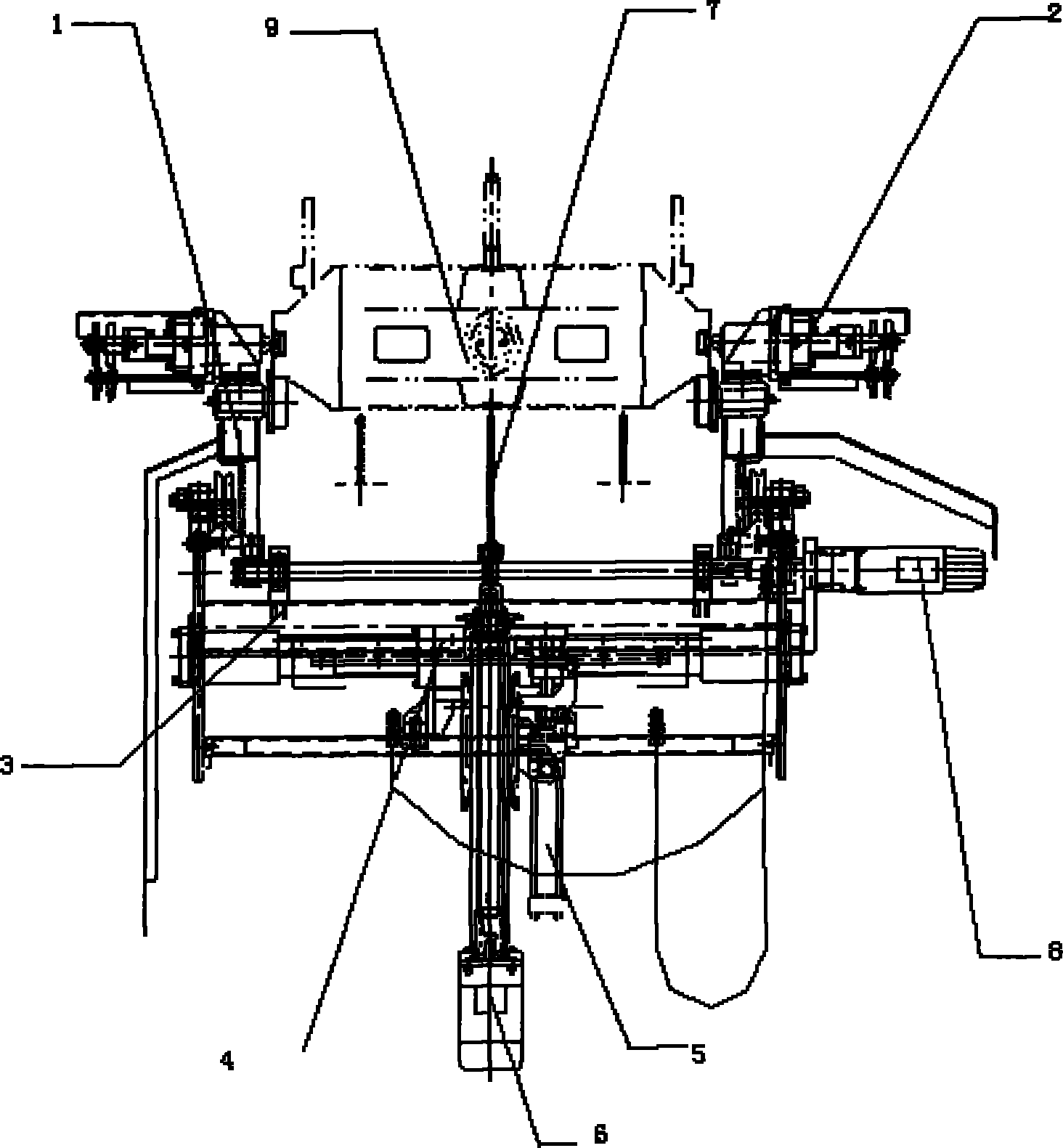

[0016] Such as figure 1 The air hole drilling device shown is used for automatic drilling of the upper box before pouring. The air hole drilling device is composed of a frame 1, a sand box positioner 2, a longitudinal moving bracket 3, a lateral moving frame 4 and a drilling mechanism. Wherein the sand box locator 2 is positioned at the upper end of the frame 1, and the air hole drilling mechanism is connected with the longitudinal moving support 3 and the lateral moving support 4. The air hole drilling mechanism includes a lifting hydraulic cylinder 5, a three-phase asynchronous motor 6 and a straight handle twist drill 7. The longitudinal movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com