Flame correcting method for rudder horn shell plate

A technology of flame rectification and shell plate, which is applied in the field of flame rectification, which can solve the problems of poor rectification effect, increase rectification work cycle, and cost, and achieve the effect of low rectification cost, high rectification efficiency and reduced process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

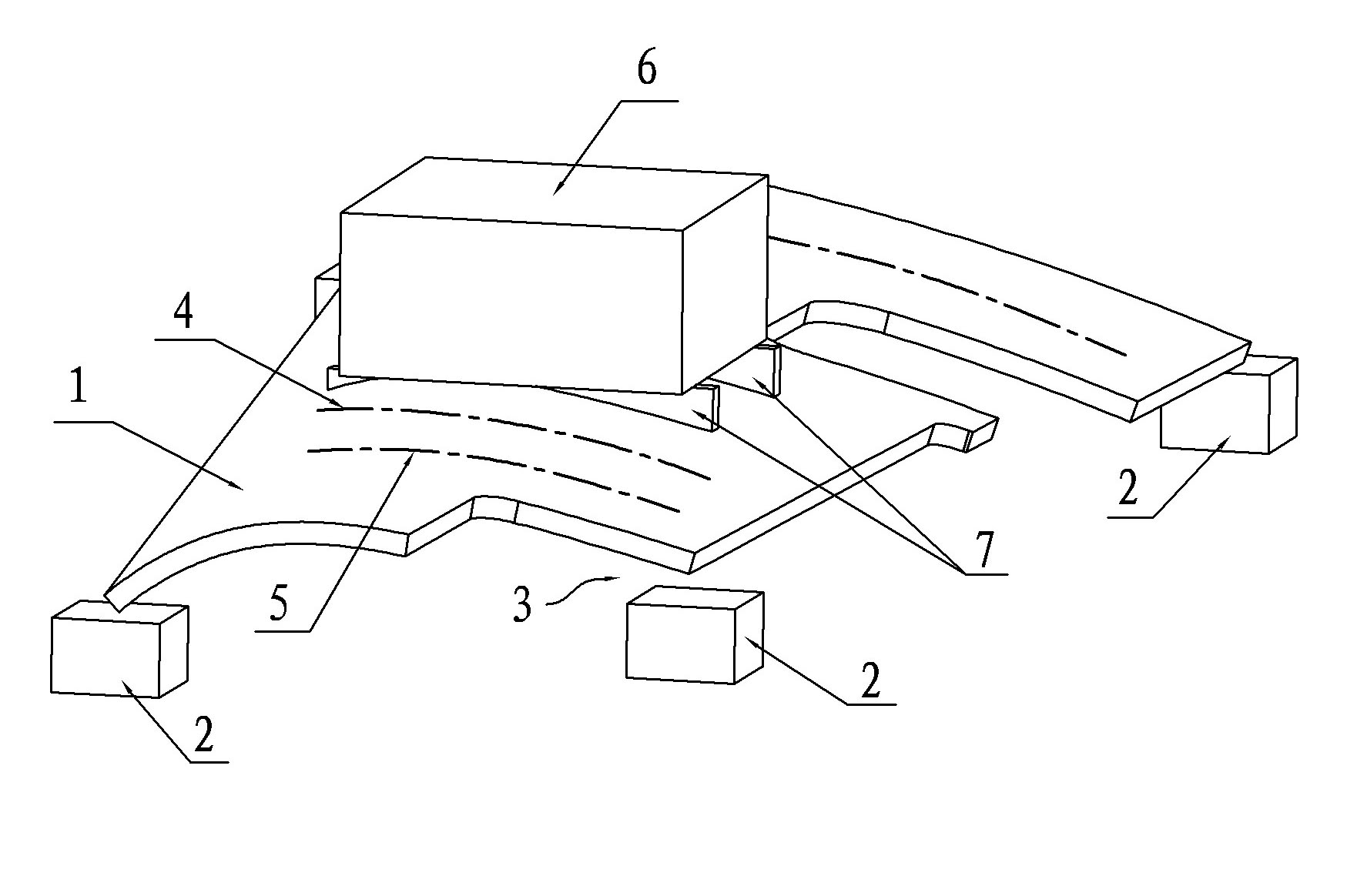

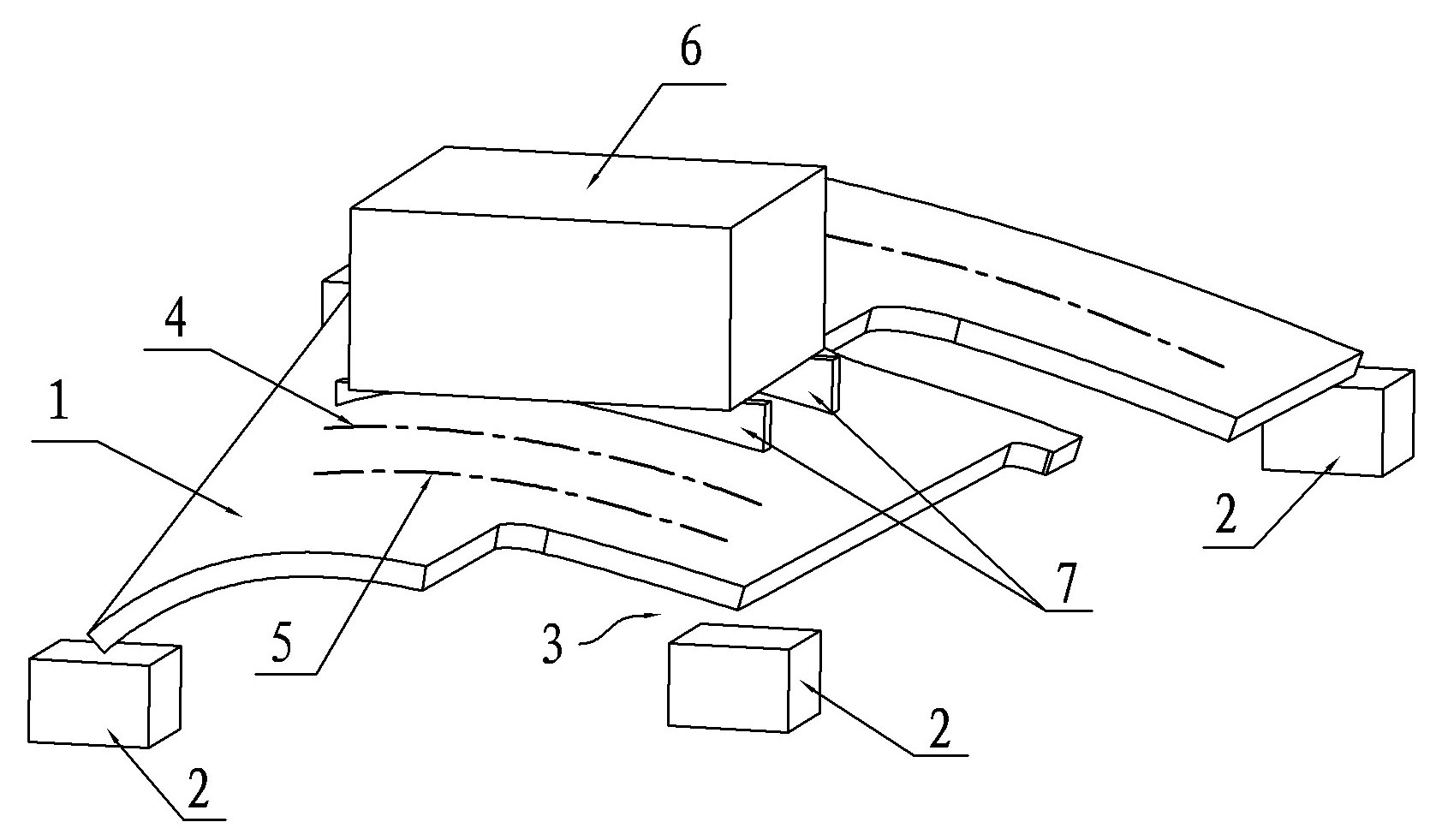

[0014] Such as figure 1 As shown, the flame rectification method of the rudder arm shell plate of the present invention, first, reverse the cold-worked rudder arm shell plate 1, and place its four corners on four pads 2 with the same height. Block 2 can be an iron block or a square wooden pad, etc. Due to the longitudinal and twisted deformation of the rudder arm shell plate 1 after cold processing, the rudder arm shell plate 1 is naturally placed behind the block 2, and the rudder arm There will be a certain gap 3 between one or a pair of corners of the shell plate 1 and the pad 2 (such as figure 1 It is shown that there is a gap between one corner and the block 2); then, according to the deformation position and deformation amount of the rudder arm shell plate 1, draw the heating line 4 longitudinally on the rudder arm shell plate 1, and in addition Apply vertical pressure on the upper surface of the rudder arm shell plate 1, so that there is an additional pressure in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com