Novel paint drying device

A drying device and paint technology, which is applied to the device for coating liquid on the surface, pretreatment surface, coating and other directions, can solve the problems of uneven temperature control of the drying box, unable to meet the lean production, easy to pollute the paint surface, etc. , to achieve the effect of favorable production arrangement, significant energy saving effect and accurate baking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

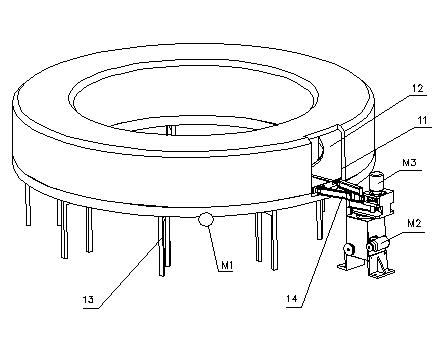

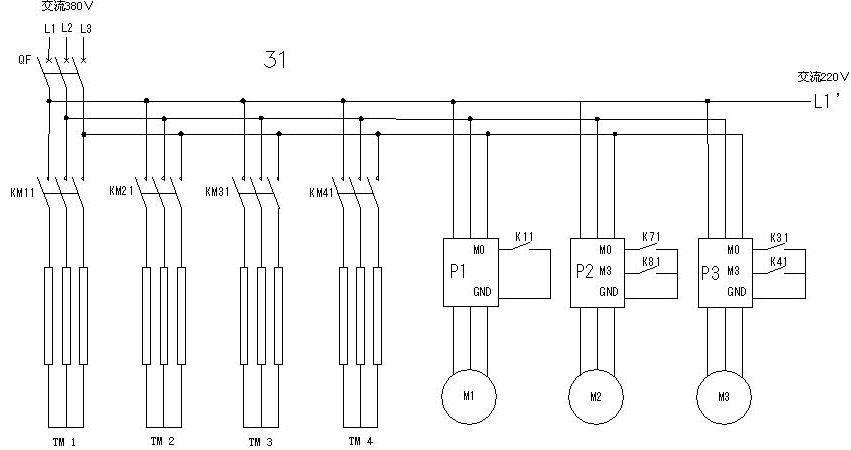

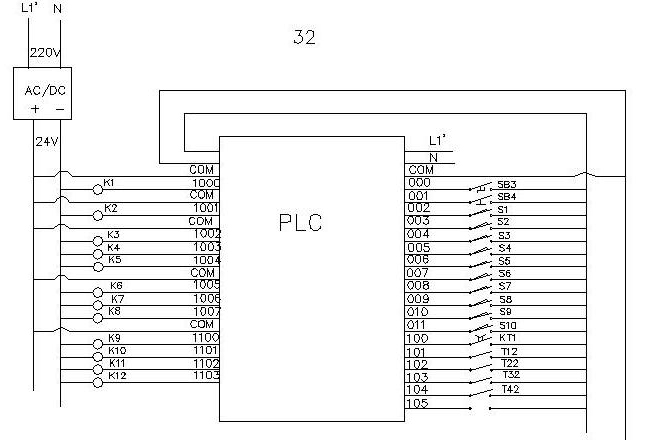

[0017] see figure 1 , A novel paint drying device of the present invention includes an oven 1, a turntable motor M1, a manipulator motor (M2, M3), a main circuit 31, an AC control circuit 32 and a DC control circuit 33. The overall structure of the oven 1 is circular (in the oven shell), and it is provided with an openable window 11 and an exhaust port for picking and placing workpieces, and a detachable movable door is installed on the window 11 . The bottom of the cavity 12 in the oven 1 is divided into several equal parts and rotatable brackets 13 for placing workpieces, and the brackets 13 form a turntable. Heating pipes are evenly distributed on both sides of the cavity 12, the cavity wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com