Cookware for electromagnetic oven as well as dedicated fixture and producing process thereof

A production process and induction cooker technology, applied in the field of kitchen utensils, can solve problems such as weak structure and poor heat conduction effect, and achieve the effects of improving heat conduction efficiency, reducing deformation, and increasing contact surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific drawings.

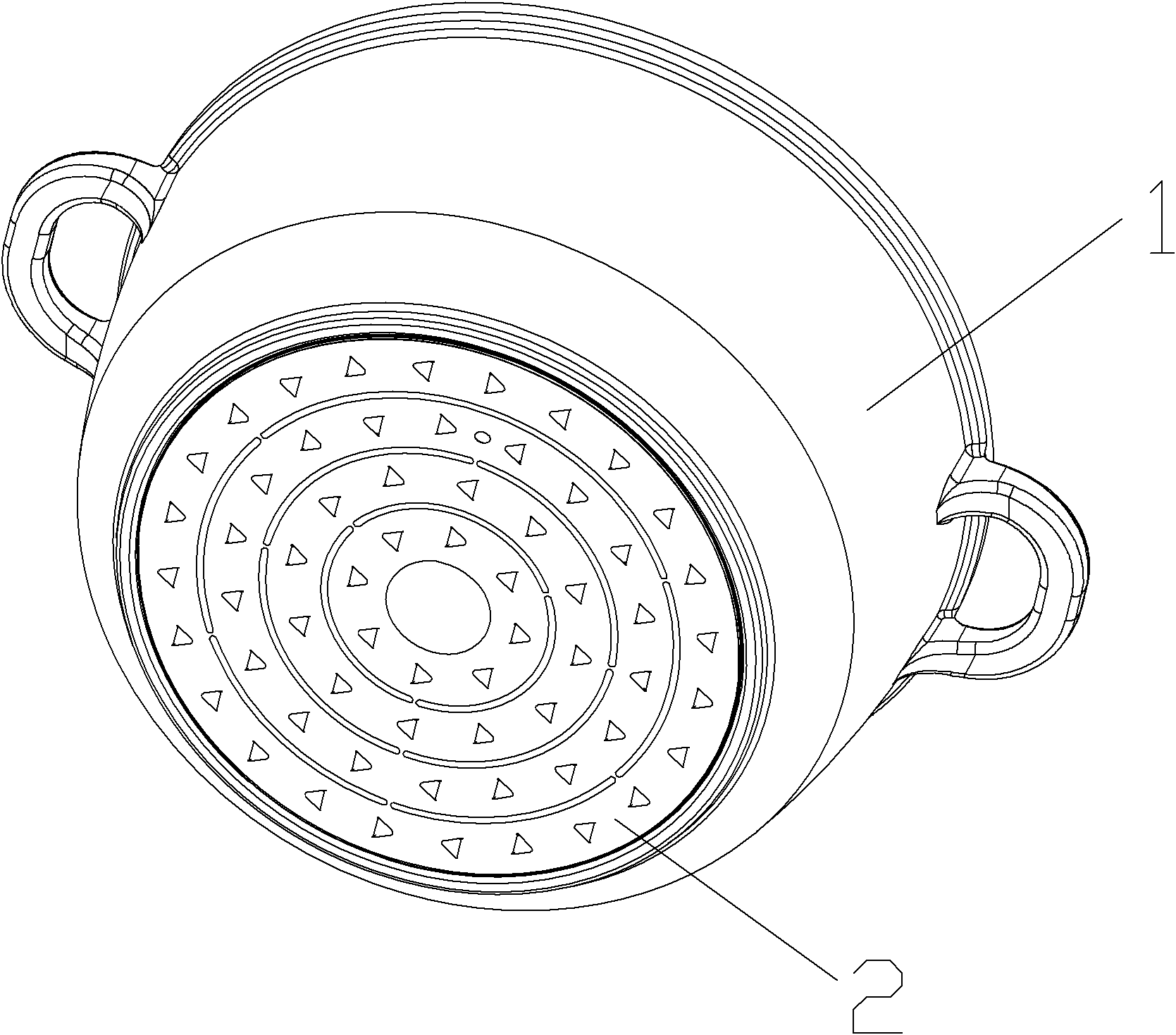

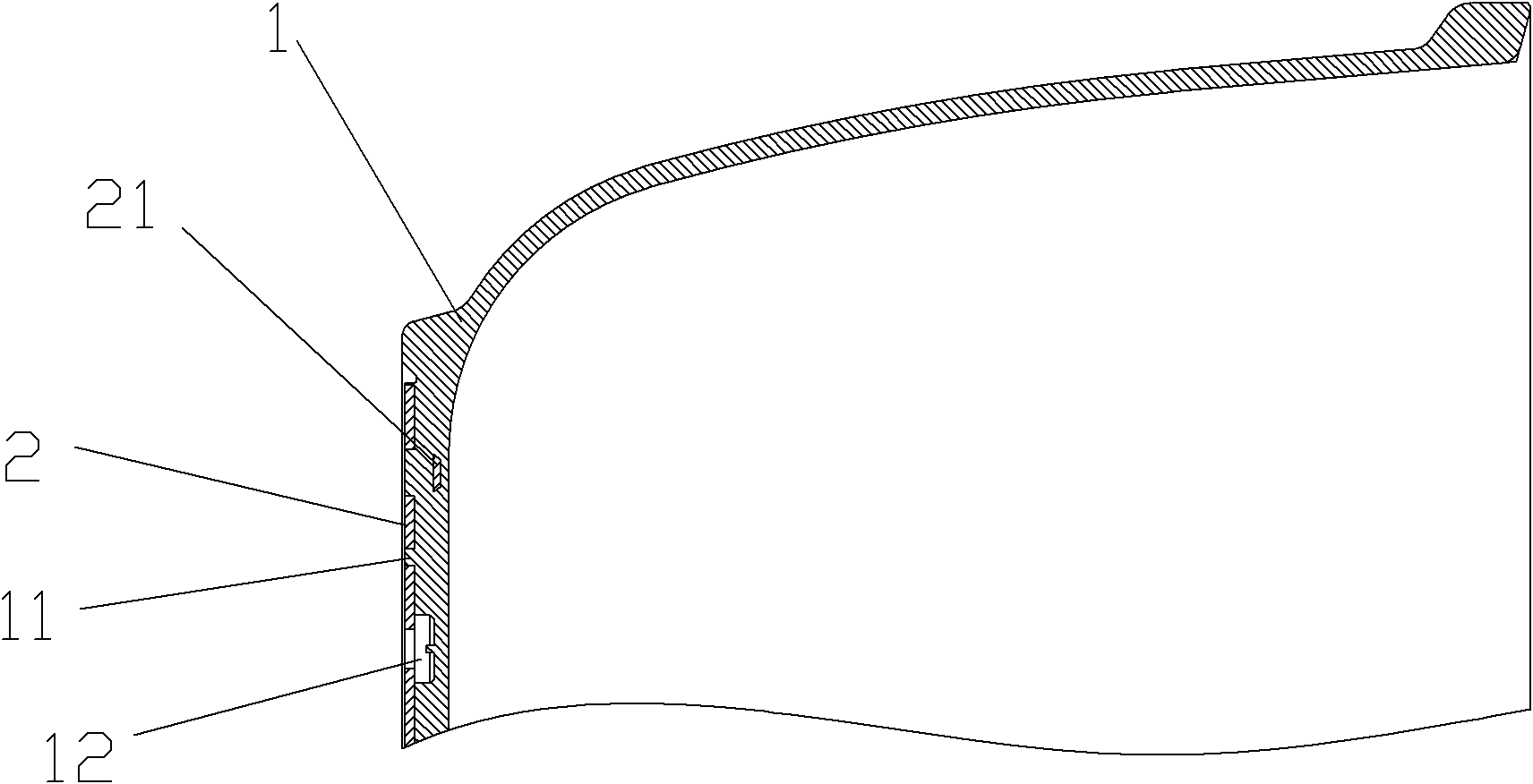

[0027] Such as Figure 1~4 As shown, the cooker for an induction cooker according to the present invention includes an aluminum pot body 1 and an iron base plate 2 that are die-cast in one, and the iron base plate 2 is pre-placed in a die-casting mold and formed into one during the die-casting process of the aluminum pot body 1 .

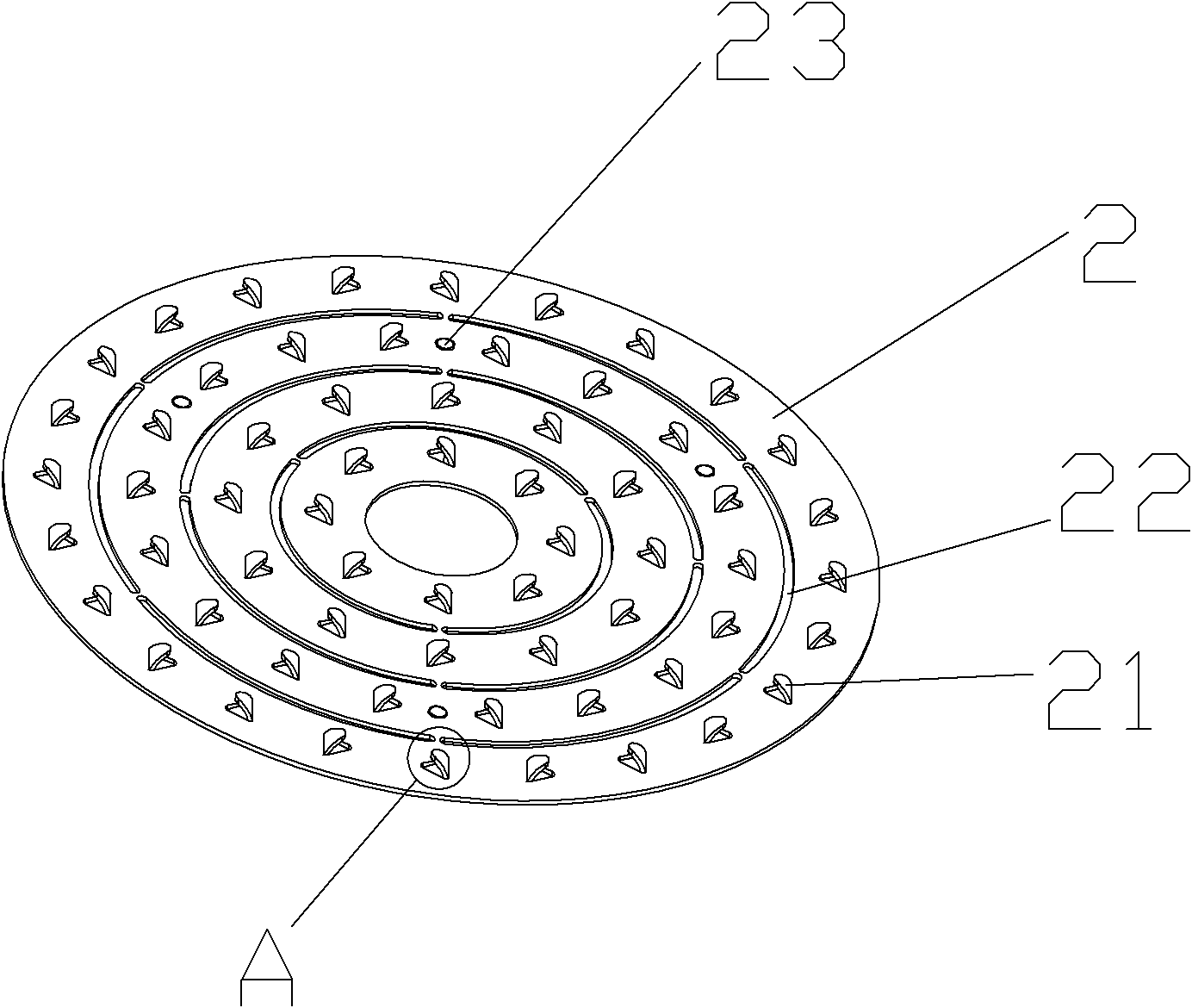

[0028] Specifically, from the structure of the pot of the present invention, the iron bottom plate 2 is circular as a whole, and several hooks 21 protrude from its surface, and the hooks 21 are embedded in the bottom of the aluminum pot body 1; and the hooks 21 are scattered on the iron bottom plate 2 On the surface, the number is large, and can be arranged regularly or irregularly, and the direction of the hook is irregular. In this embodiment, the hook 21 is formed by punching the iron base plate 2 , and is formed with several punching holes 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com