Integral-stalk tip-breaking leaf-peeling and crushing integrated mechanism for sugarcane harvester

A harvester and leaf stripping technology, which is applied to harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of affecting harvesting efficiency, single operation function, and failure to comb sugarcane leaves in advance, so as to achieve simple structure, Clean, fully functional effect of peeling leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

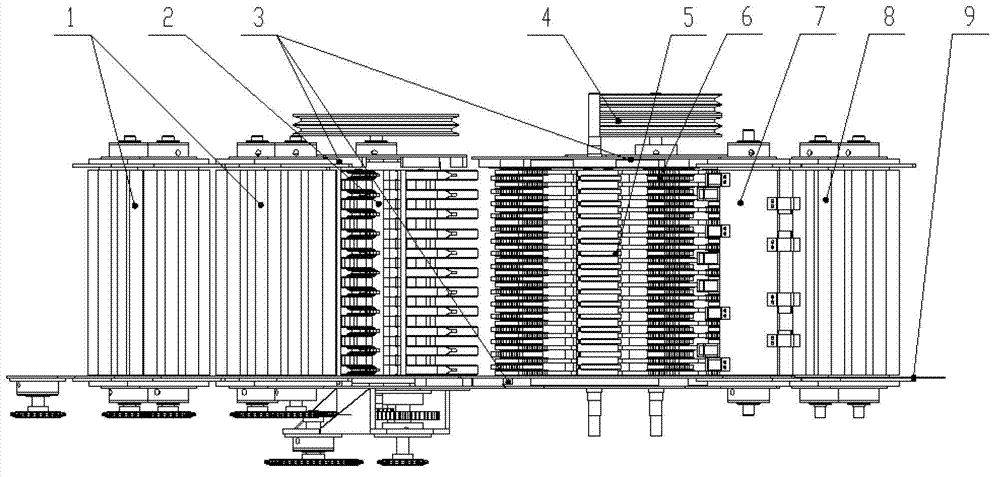

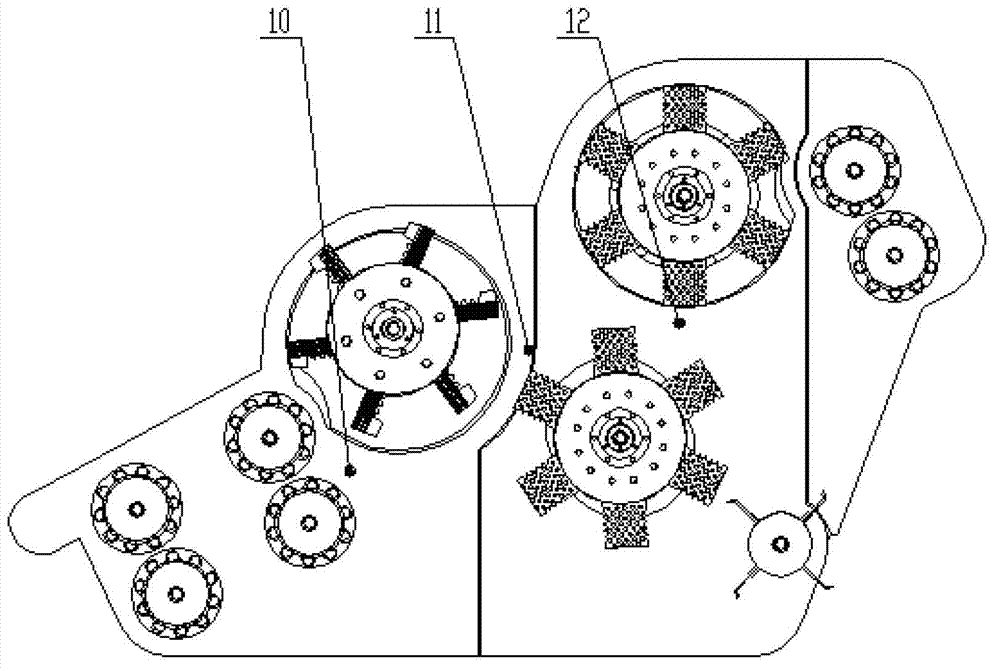

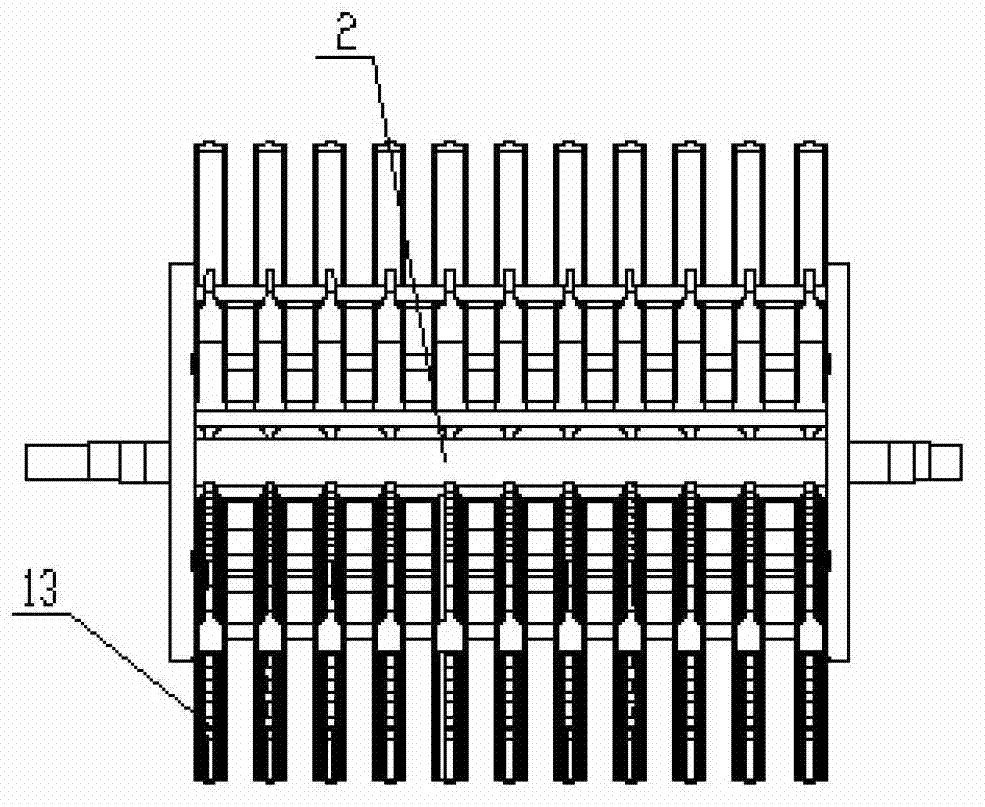

[0046] Whole stalk sugarcane harvester integrated mechanism for breaking and peeling leaves and leaves, input roller 1, level I tip breaking device 10, rake roller 2, level II tip breaking device 11, upper leaf stripping roller 5, and level III tip breaking device 12. The lower leaf stripping roller 6, the crushing leaf roller 7, and the output roller 8 are installed on the frame 9 from front to back in sequence. The transmission mechanism 4 adopts a combination structure of sprocket, pulley and gear transmission, and the tip of each level is broken. The device is supported by a pair of sliding bearings. The leaf raking roller and a pair of leaf stripping rollers form an inverted "product" arrangement; according to the sugarcane of different sizes, the leaf raking roller 5 and the leaf stripping roller 6, the leaf stripping roller 6 and the upper leaf stripping roller are adjusted appropriately. The distance between the outer rim of the leaf stripping roller 5; the leaf rake r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com