Device for testing different cracking conditions of interior of cement-based material and method

A cement-based material and test piece technology, applied in the direction of material resistance, can solve the problem of difficult detection of deep internal defects in concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

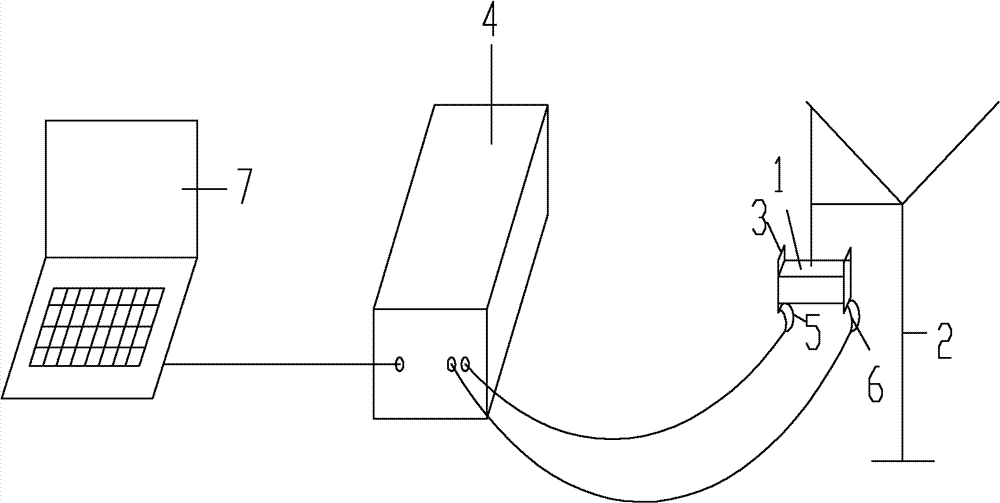

[0022] In order to verify that AC impedance spectroscopy can be used to test different cracking conditions inside cement-based materials, the test specimens of cement paste and fly ash cement paste were selected in the test, and the water-cement ratio was 0.3 and 0.35 respectively. Four levels of load are applied inside, and the test is carried out in accordance with the following steps in conjunction with the attached drawings.

[0023] 1. Make 2 identical groups and each group has 4 standard cement-based material specimens 1 with a size of 40×40×160mm. The specimen numbers and mix design are shown in Table 1. Cured in a water bath for 3 days according to the standard method, then took it out, and wiped the surface of the specimen with a dry and clean rag. The first group of specimens were wrapped and sealed with plastic film around them, and the flexural strength of the second group of specimens was measured in parallel.

[0024] 2. Fix each test piece 1 in the second group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com