Grid cloth digital printing material and manufacture process thereof

A technology of digital printing and mesh cloth, applied in the direction of synthetic resin layered products, textiles and papermaking, layered products, etc., can solve the problems of poor air permeability, easy tearing, falling off, poor air permeability and wind resistance of advertising cloth, etc. , to achieve the effect of prolonging the service life, enhancing the wind resistance and good wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

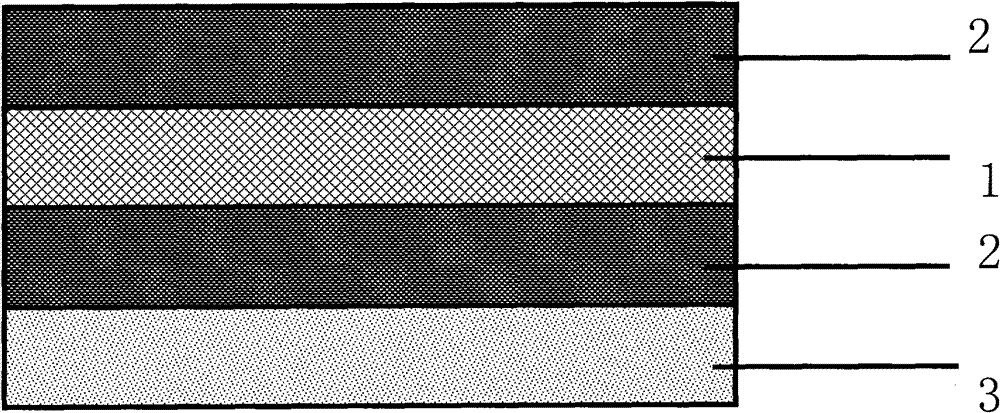

[0014] exist figure 1 Among them, the present invention is a layered structure, which includes a base fabric 1 made of high-strength polyester filaments, the two sides of the base fabric 1 are coated with a polymer coating 2, and the outermost layer is laminated with a PVC base film 3. The base cloth 1 has a thickness of 0.1-0.2 mm, the polymer coating 2 has a thickness of 0.1-0.3 mm, and the PVC base film 3 has a thickness of 0.05-0.1 mm.

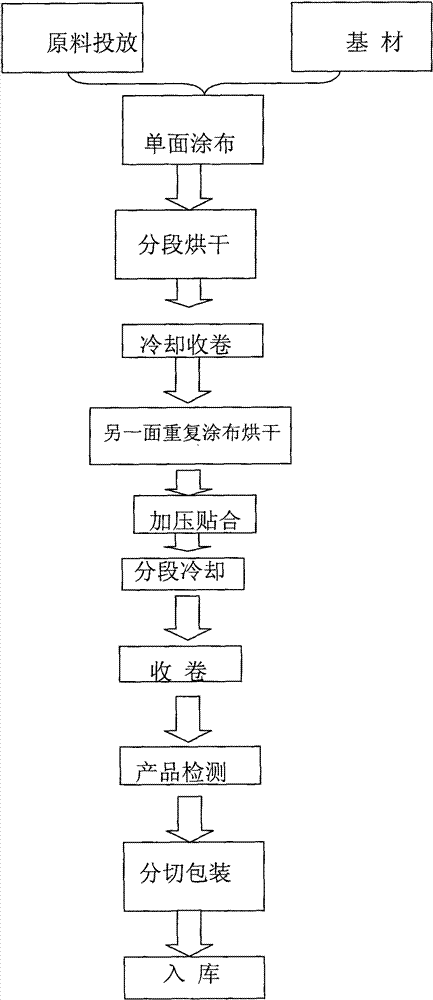

[0015] exist figure 2 Among them, the steps of the production process of the present invention are to use raw materials and substrates to put in-one-sided coating-segmented drying-cooling and winding-repeated coating and drying on the other side-pressurization lamination-segmented cooling-winding -Product testing-slitting and packaging-warehousing to complete.

[0016] Specific steps are as follows:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com