Environmentally friendly building block

An environmentally friendly and block-based technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of high cost, environmental damage, energy consumption, etc., and achieve the effect of low cost and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

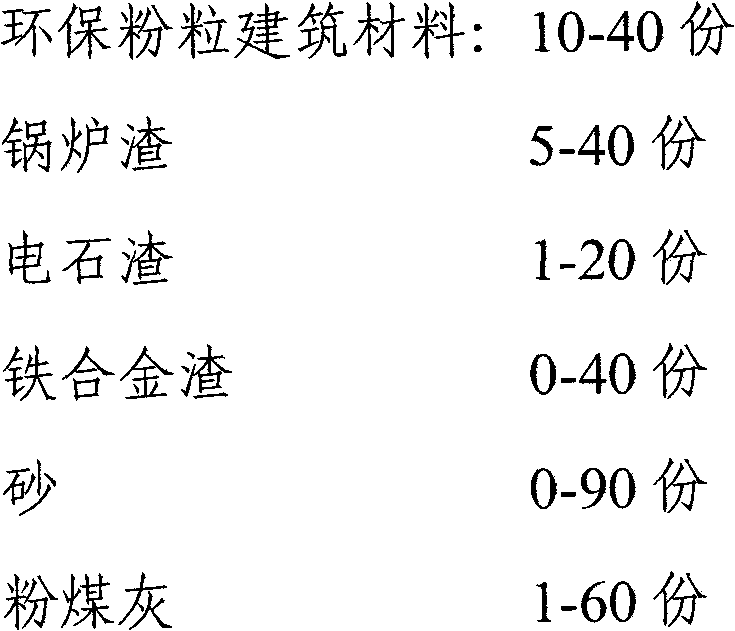

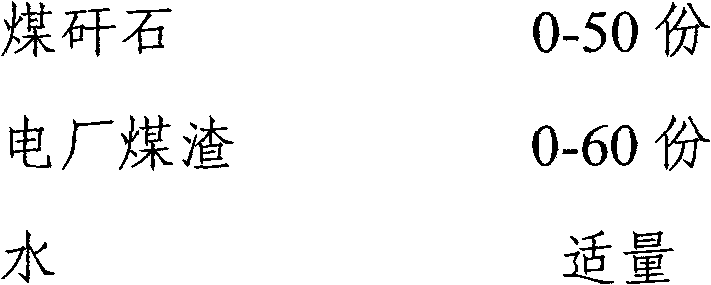

[0008] Embodiment 1: for producing solid standard block (brick), its preparation composition and parts by weight are:

[0009]

[0010]

[0011] The preparation method includes the steps of raw material storage—measurement—feeding and stirring—forming—stationary maintenance. The feeding and stirring step is to first throw aggregate and filler, and then throw in environmental protection powder building materials, stir for 10-30 seconds, mix evenly, and then Add water and stir, stir for 0.5-2 minutes, send it to the molding machine for molding, and then maintain it to make a finished product.

Embodiment 2

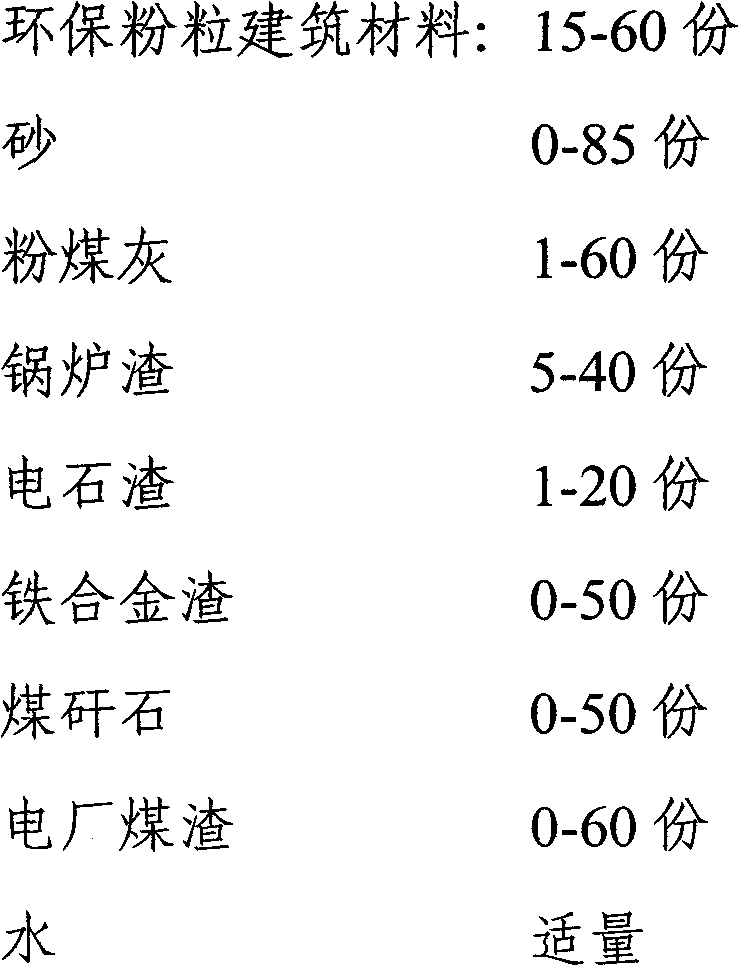

[0012] Embodiment 2: for producing hollow block, its preparation composition and parts by weight are:

[0013]

[0014] The preparation method includes the steps of raw material storage—measurement—feeding and stirring—forming—stationary maintenance. The feeding and stirring step is to first throw aggregate and filler, and then throw in environmental protection powder building materials, stir for 10-30 seconds, mix evenly, and then Add water and stir, stir for 0.5-2 minutes, send it to the molding machine for molding, and then maintain it to make a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com