Integral female die with good punching effect

A concave die, integrated technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems affecting the surface quality of steel strips, products are easily broken, and achieve the effect of improving product quality and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

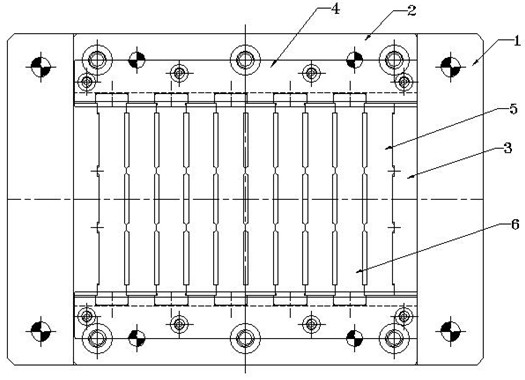

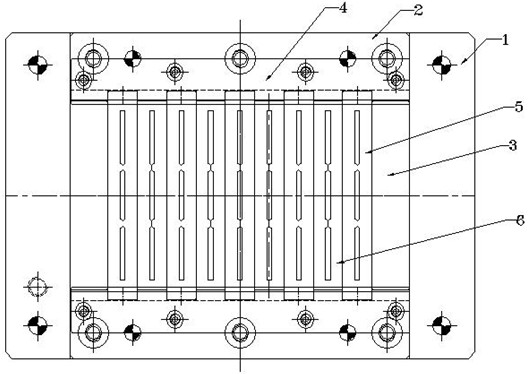

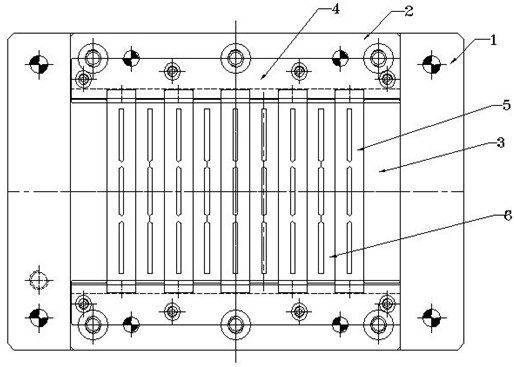

[0011] like figure 2 As shown, the present invention provides a good integral die of stamping effect, consisting of die base 1, die positioning block 2, die stopper 3, die bead 4, first die 5, second die 6 composition. Use five first dies 5, four second dies 6 and two die stoppers 3 to fit side by side into the groove of the die holder 1 and fix the first die 5 and the second die by the groove of the die positioning block 2. The position of the two dies 6, and cut pin holes on the die positioning block 2 and the die base 1 to fix the position of the die. Push down the first die 5, the second die 6 and the die stopper 3 with the die bead 4.

[0012] When working, the unloading block is pressed on the part of the inlaid concave mold, and the joint of the concave mold insert is not at the connecting rib of the steel belt product, which can effectively remove the imprint of the connecting rib.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com