Piezoelectric microfluidic mixer

A technology of microfluidics and mixers, which is applied in the direction of fluid mixers, mixers, fluid velocity measurement, etc., can solve the problems of prolonged mixing time, poor mixing effect, small Reynolds number, etc., achieve good mixing effect and promote mixing , fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

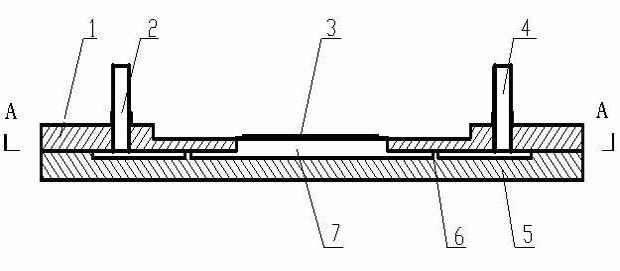

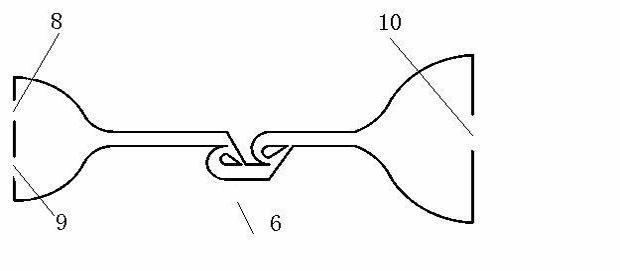

[0015] Such as Figure 1-2 , the present invention has a pump body 5, the material of the pump body 5 is a silicon chip, the upper part of the pump body 5 is an upper substrate 1, the materials of the pump body 5 and the upper substrate 1 are glass, and the pump body 5 and the upper substrate 1 are bonded by an anode Combining technology together. On the upper substrate 1, two pump inlets 2, one pump outlet 4 and one pump chamber 7 are processed by laser, wherein the pump chamber 7 is located in the middle of the upper substrate 1, and the pump inlet 2 and pump outlet 4 are respectively located on the two sides of the pump chamber 7. side. The radius of the pump cavity 7 is 1500 Å, and the height of the pump cavity 7 is 130 Å. The inlet cavity and the outlet cavity are processed on the pump body 5 by dry etching process, the inlet cavity communicates with the pump inlet 2 on the upper substrate 1 , and the outlet cavity communicates with the pump outlet 4 on the upper substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com