Method for cleaning filtering membrane modules

A filter membrane and membrane module technology, which is applied in the cleaning field of filter membrane modules, can solve problems such as high energy consumption, high power consumption, and membrane material damage, and achieve the effects of restoring separation function, prolonging service life, and rapid cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

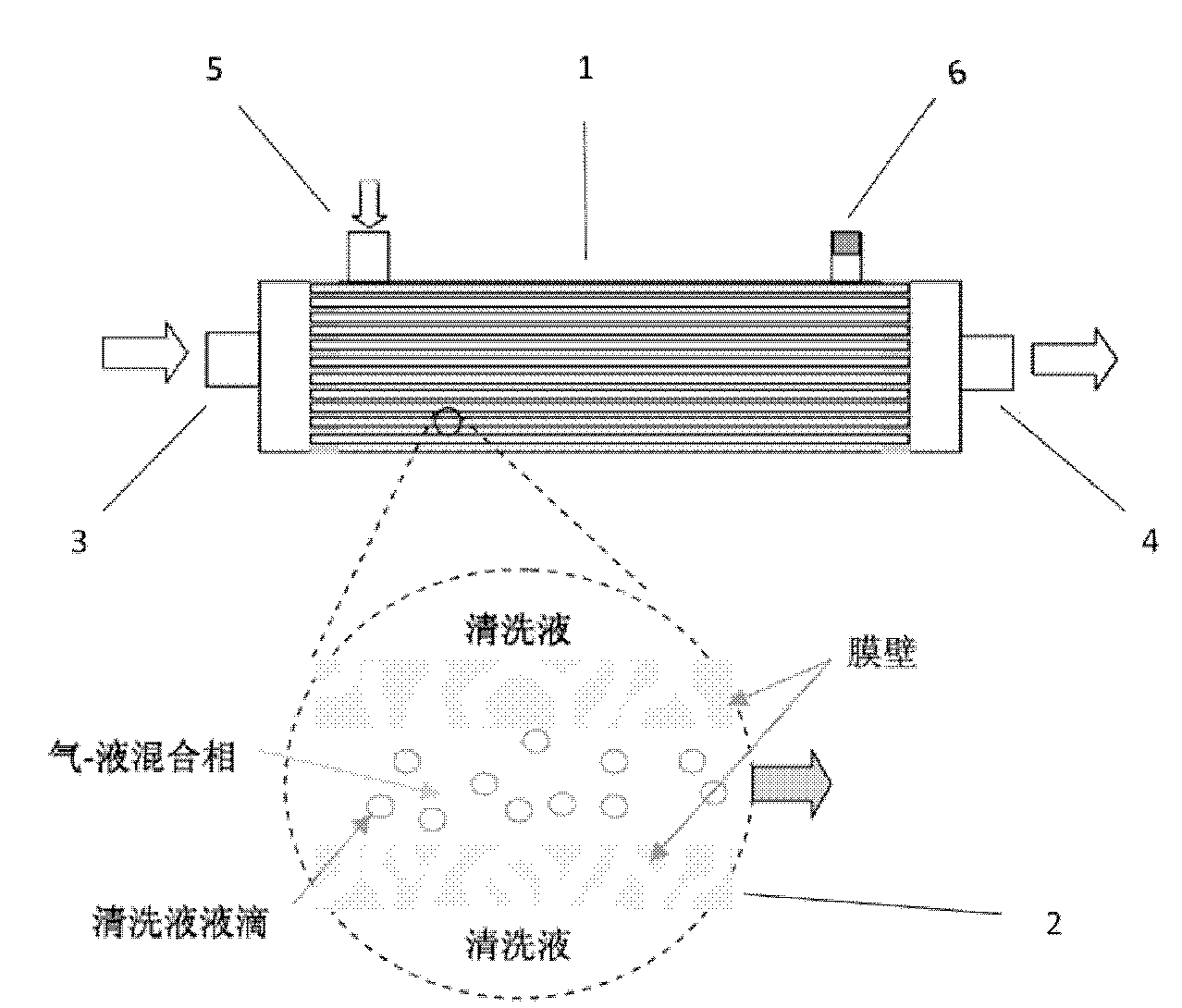

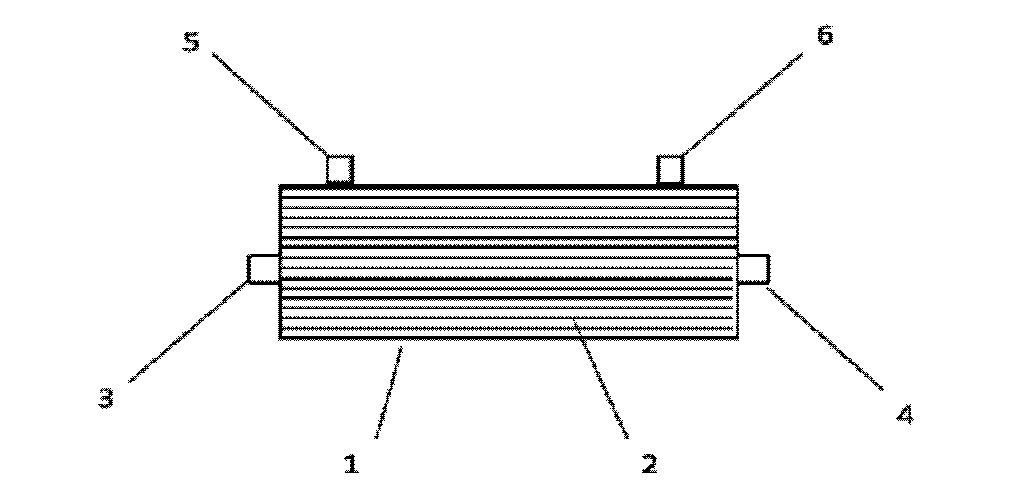

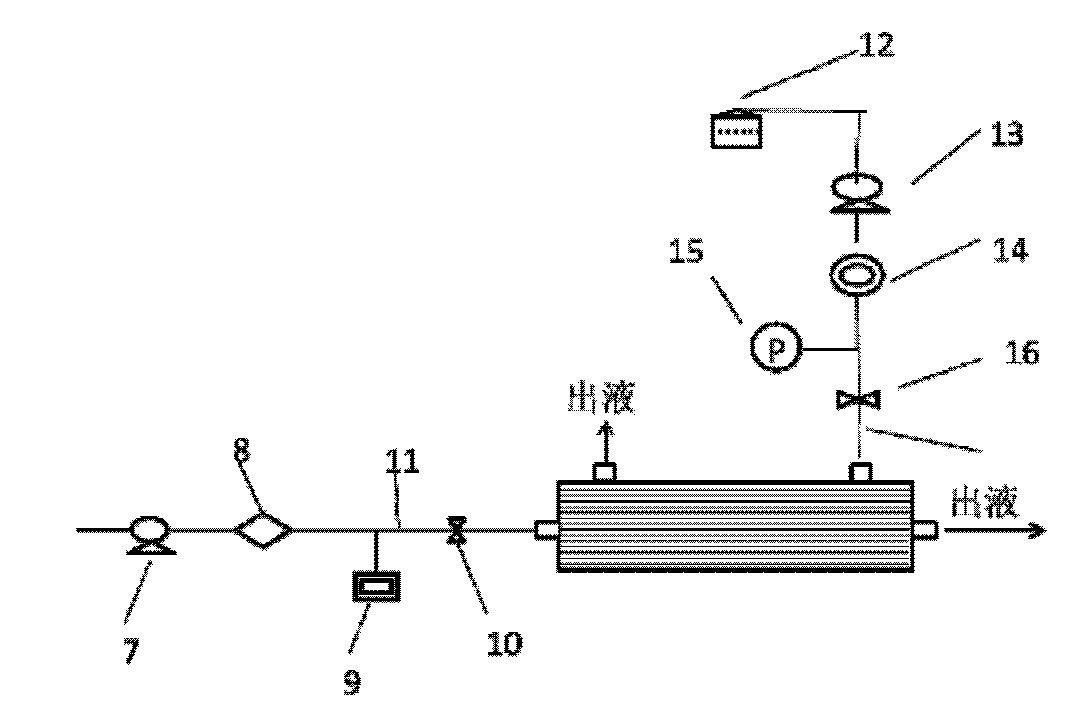

[0026] 1) Heat clean water as the cleaning liquid to 20°C in the liquid storage tank, and then adjust the flow rate to 100ml / min to enter the shell side of the hollow fiber membrane module. Clean water enters continuously from the inlet 5 of the shell side of the hollow fiber membrane module, flows out from the outlet 6 of the shell side and is drained away without recycling.

[0027] 2) Close the inlets 3 and 6, the aforementioned steps are the same as 1), the cleaning liquid enters from the hollow fiber ultrafiltration membrane module shell side inlet 5, flows out from the tube side outlet 4, and does not recycle;

[0028] Switch the flow direction valve, close the inlets 4 and 5, the aforementioned steps are the same as 1), the cleaning liquid enters from the shell side inlet 6 of the hollow fiber ultrafiltration membrane module, flows out from the tube side outlet 3, and is not recycled;

[0029] Repeat process 2) three times.

[0030] 3) The inlet 5 of the shell side is ...

Embodiment 2

[0037] 1) Heat clean water as the cleaning liquid to 20°C in the liquid storage tank, and then adjust the flow rate to 100ml / min to enter the shell side of the hollow fiber membrane module. Clean water enters continuously from the inlet 5 of the shell side of the hollow fiber membrane module, flows out from the outlet 6 of the shell side and is drained away without recycling.

[0038] 2) Close the inlets 3 and 6, the aforementioned steps are the same as 1), the cleaning liquid enters from the hollow fiber ultrafiltration membrane module shell side inlet 5, flows out from the tube side outlet 4, and does not recycle;

[0039] Switch the flow direction valve, close the inlets 4 and 5, the aforementioned steps are the same as 1), the cleaning liquid enters from the shell side inlet 6 of the hollow fiber ultrafiltration membrane module, flows out from the tube side outlet 3, and is not recycled;

[0040] Repeat process 2) three times.

[0041] 3) The inlet 5 of the shell side is ...

Embodiment 3

[0048] 1) Heat clean water as the cleaning liquid to 20°C in the liquid storage tank, and then adjust the flow rate to 100ml / min to enter the shell side of the hollow fiber membrane module. Clean water enters continuously from the inlet 5 of the shell side of the hollow fiber membrane module, flows out from the outlet 6 of the shell side and is drained away without recycling.

[0049] 2) Close the inlets 3 and 6, the aforementioned steps are the same as 1), the cleaning liquid enters from the hollow fiber ultrafiltration membrane module shell side inlet 5, flows out from the tube side outlet 4, and does not recycle;

[0050] Switch the flow direction valve, close the inlets 4 and 5, the aforementioned steps are the same as 1), the cleaning liquid enters from the shell side inlet 6 of the hollow fiber ultrafiltration membrane module, flows out from the tube side outlet 3, and is not recycled;

[0051] Repeat process 2) three times.

[0052] 3) The inlet 5 of the shell side is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com