Spiral phase plate with adjustable parameters

A spiral phase plate and parameter technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of high diffraction efficiency, non-adjustable topological charge, and high processing accuracy requirements, and achieve simple optical path structure, simplified manufacturing process, and conversion efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

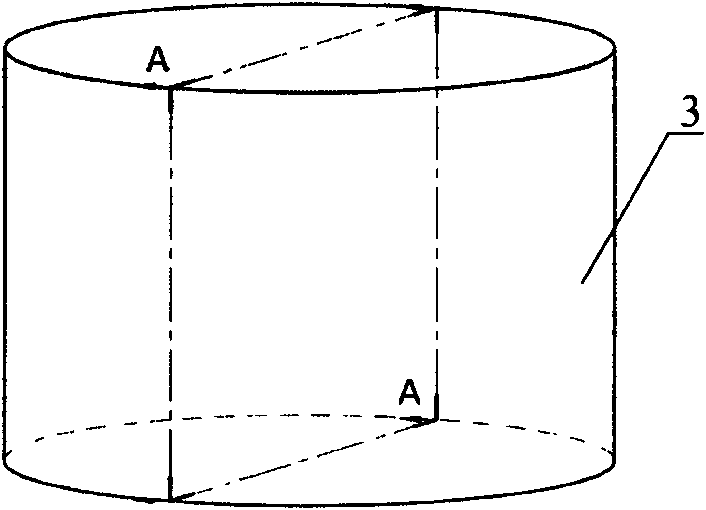

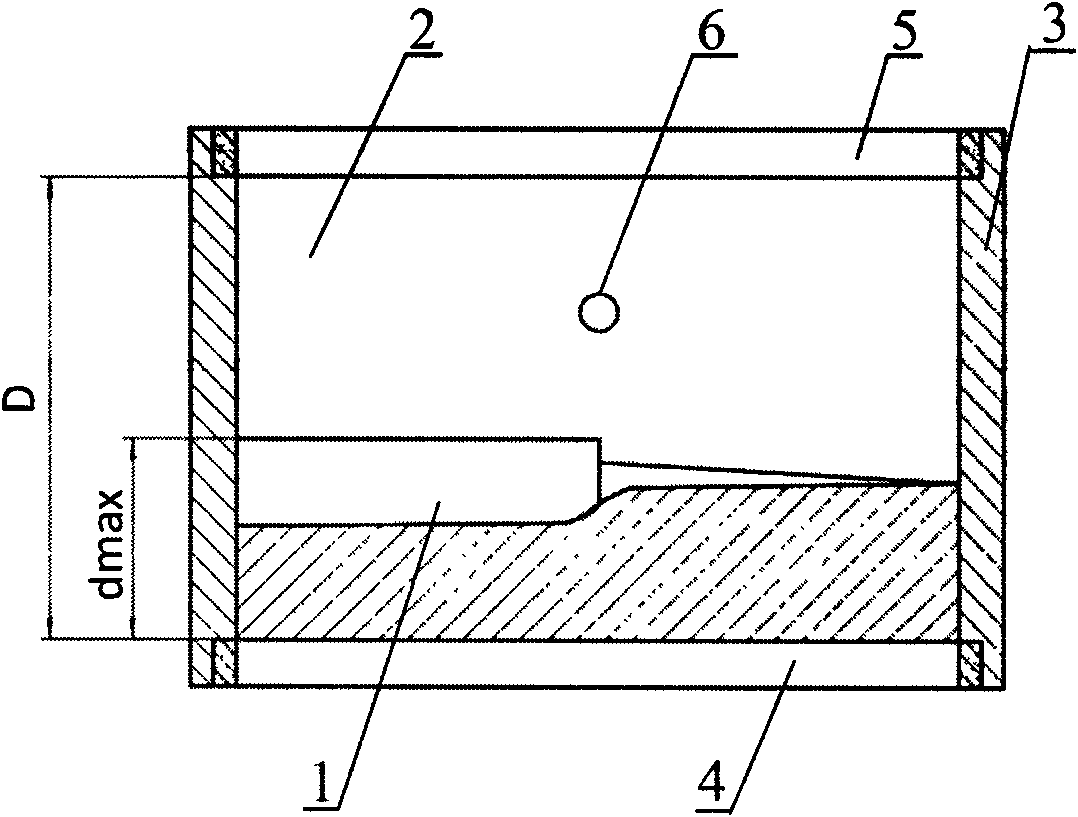

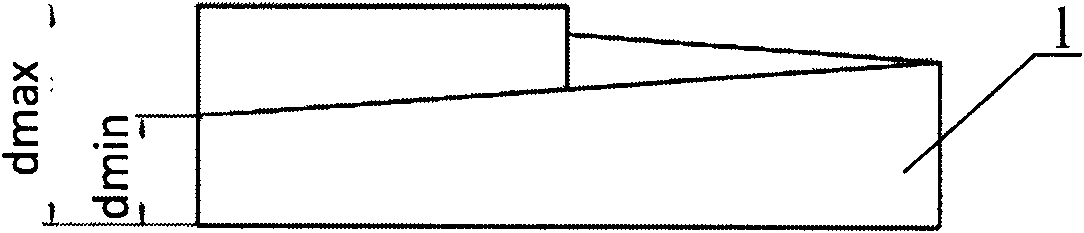

[0043] refer to Figure 1-a to Figure 2-b . This embodiment includes a transparent solid helical phase plate 1 (left-handed from thick to thin), a refractive index matching liquid 2 , and a cylindrical transparent container 3 . The bottom plane of the solid spiral phase plate 1 is in close contact with the incident surface 4 at the bottom end of the cylindrical transparent container 3 . The cavity between the upper end surface 5 of the cylindrical transparent container 3 and the spiral phase plate 1 is filled with a refractive index matching liquid 2 . A matching liquid injection hole 6 is opened on one side of the cylindrical container. In this embodiment, matching liquids with different refractive indices need to be selected in advance and injected through the injection hole 6 . The solid helical phase plate is made of transparent materials. In this embodiment, crown glass is taken as an example to make a solid helical phase plate with a thickness difference Δd=0.02 mm. U...

Embodiment 2

[0050] refer to Figure 3-a to Figure 4-b . This embodiment includes a transparent solid helical phase plate 1 (left-handed from thick to thin), a refractive index matching liquid 2 and a cylindrical transparent container 3 . The outer surfaces of the incident end face 4 and the upper end face 5 of the cylindrical container are covered with transparent electrodes 7 and 8, respectively. The bottom plane of the solid spiral phase plate 1 is in close contact with the bottom incident surface 4 of the cylindrical transparent container 3 . The cavity between the upper end surface 5 of the cylindrical transparent container 3 and the spiral phase plate 1 is filled with a refractive index matching liquid 2 . The transparent solid helical phase plate 1 is made of electro-optic crystal, and one of its electric field-induced dielectric main axes (denoted as z′ axis) is perpendicular to the bottom surface of the phase plate and points to the top, parallel to the incident light beam, and ...

Embodiment 3

[0064] refer to Figures 5-a to 6-b . This embodiment includes a transparent solid helical phase plate 1 (cuboid, the bottom surface is a square with a side length 1, and the helical part is left-handed from thick to thin, as shown in FIG. 6 ), a refractive index matching liquid 2, and a cuboid container 3 . The bottom plane of the solid spiral phase plate 1 is in close contact with the incident surface 4 at the bottom end of the square container 3 . The cavity between the upper end surface 5 of the square container 3 and the spiral phase plate 1 is filled with a refractive index matching liquid 2 . The outer surfaces of the two opposite sides of the cuboid container 3 are respectively covered with the first opaque electrode 9 and the second opaque electrode 10 . The transparent solid helical phase plate 1 is made of electro-optic crystal, one of its electric field induced dielectric main axes (denoted as z′ axis) is parallel to the bottom surface of the phase plate, perpend...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com