Anti-stripping test device for surface aggregates of porous pavements

A technology of porous pavement and test device, which is applied in the direction of measuring device, using mechanical device, analyzing materials, etc., can solve problems such as affecting the function of pavement surface, damage of pavement structure strength, peeling of pavement surface particles, etc., and achieves simple and flexible parameter setting. , Simple manufacturing and testing, and intuitive test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

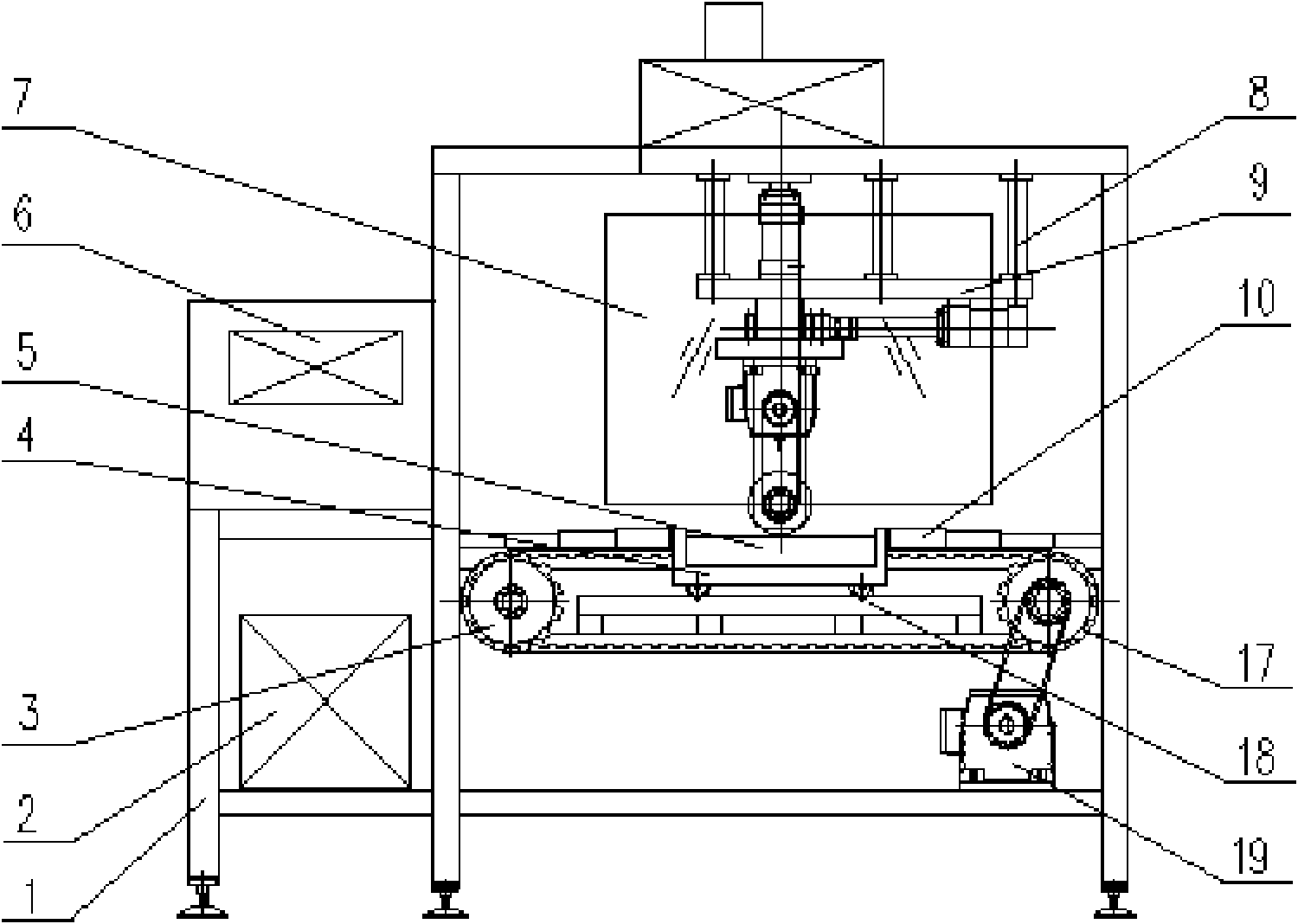

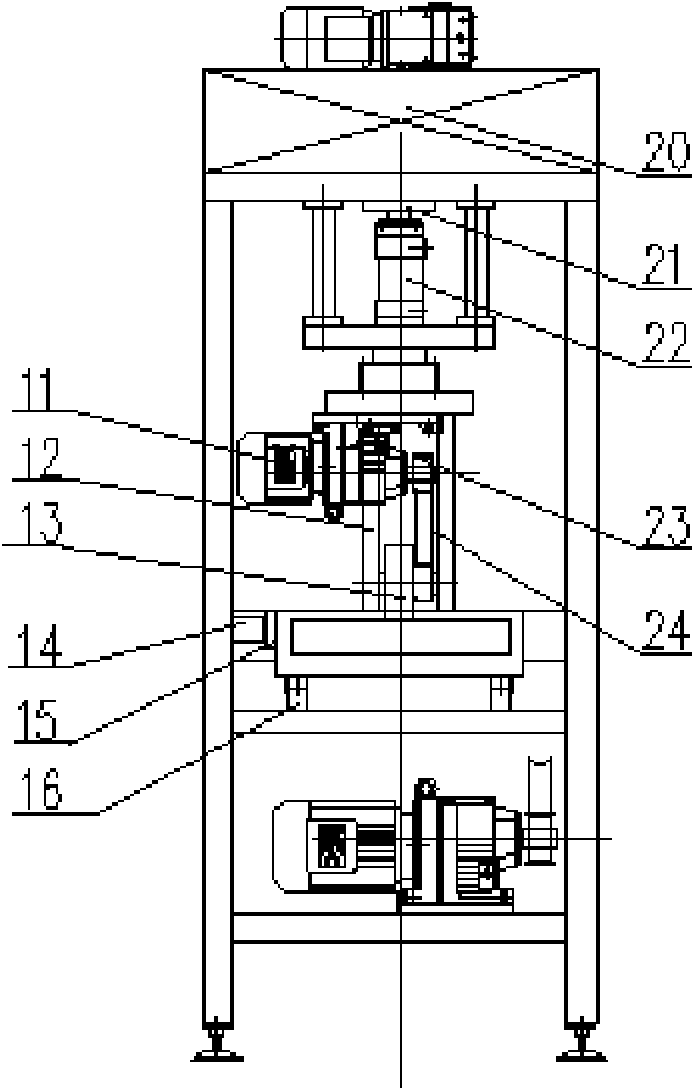

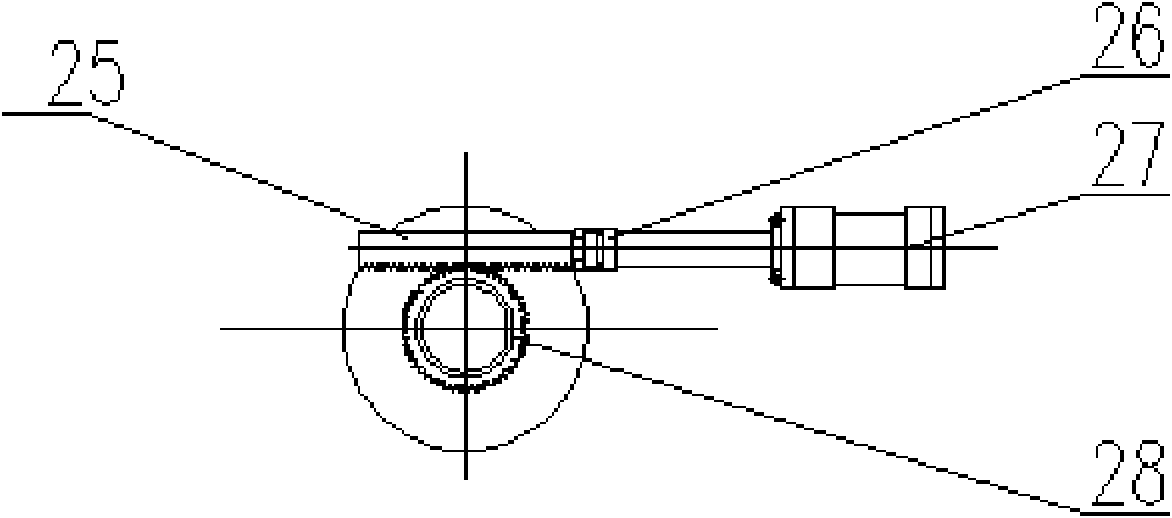

[0019] refer to figure 1 , figure 2 , image 3 As shown in the figure: 1. Support frame; 2. Temperature controller; 3. Synchronous pulley; 4. Test piece assembly area; 5. Test piece; 6. Visual control platform; 7. Observation window; 8. Connecting pillar ;9, support plate; 10, pull plate; 11, servo motor; 12, support frame; 13, rubber wheel; 14 travel switch; 19, reduction motor; 20, hydraulic station; 21, pressure plate; 22, hydraulic cylinder; 23, synchronous wheel; 24 synchronous belt; 25, rack; 26, joint; 27, hydraulic cylinder; 28, gear.

[0020] The test device is equipped with a deceleration motor 19 at the lower right part of the support frame 1, and the deceleration motor 19 drives the left and right drive wheels 3 in the middle of the support frame to move through the synchronous belt. 1. The rubber wheel 13 links to each other with the synchronous wheel 23 on the servo motor 11 through the synchronous belt 24, is fixed on the wheel steering control mechanism on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com