Valve plate structure improving efficiency of piston compressor

A compressor and piston type technology, which is applied in the direction of liquid variable capacity machinery, mechanical equipment, variable capacity pump components, etc., can solve the problems of high cost, easy leakage, complex process, etc., and achieve the goal of reducing processing costs and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

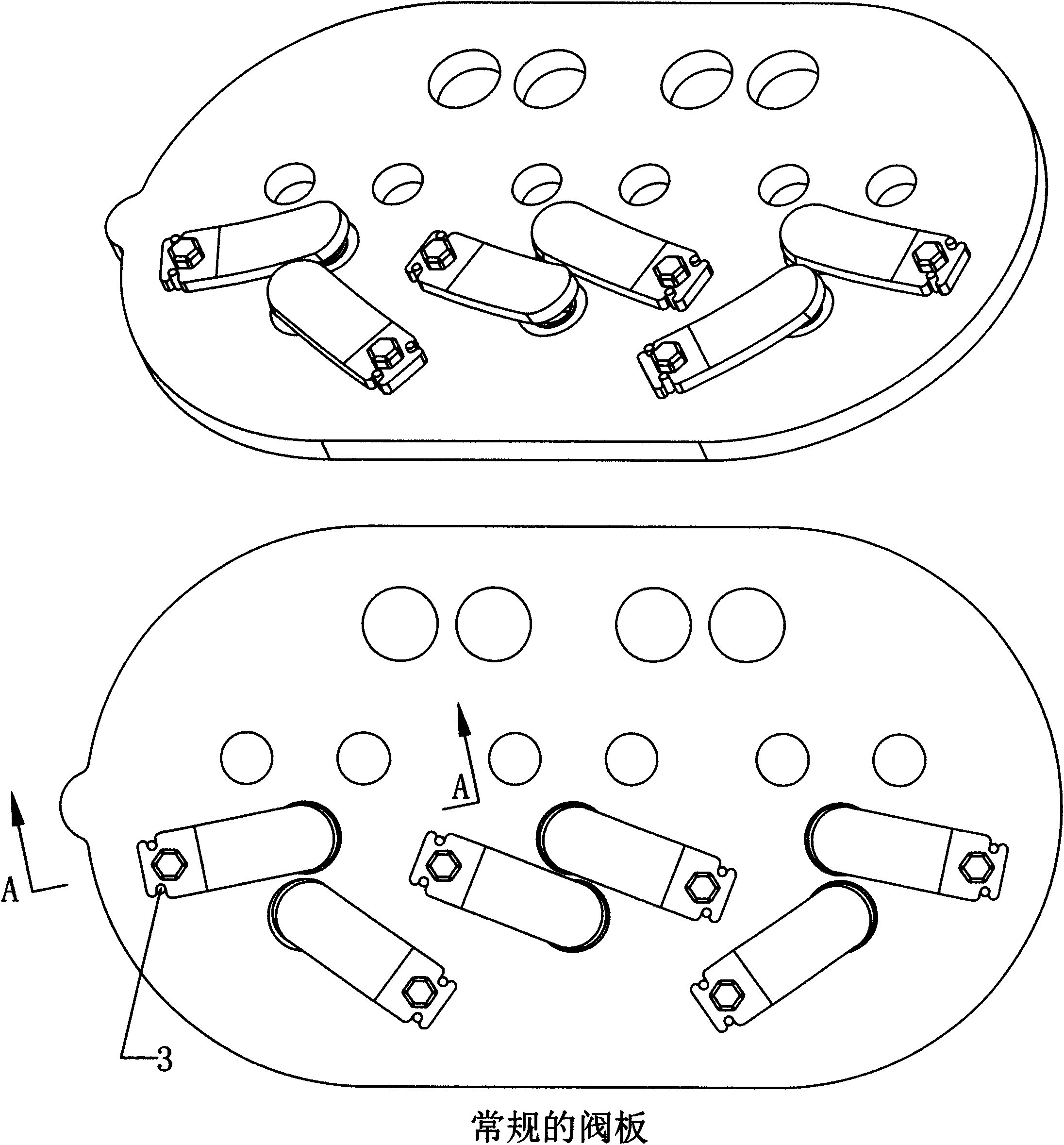

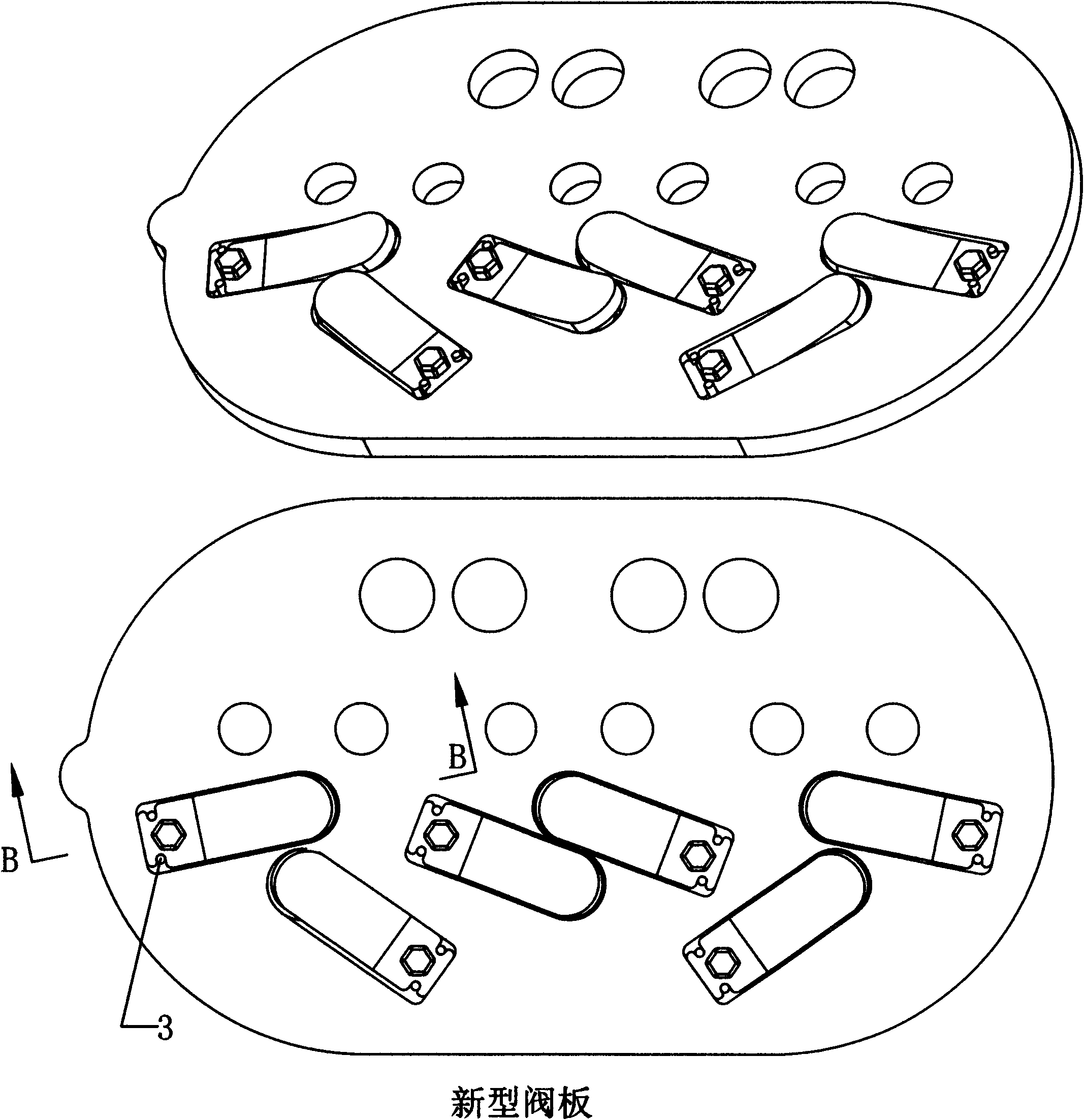

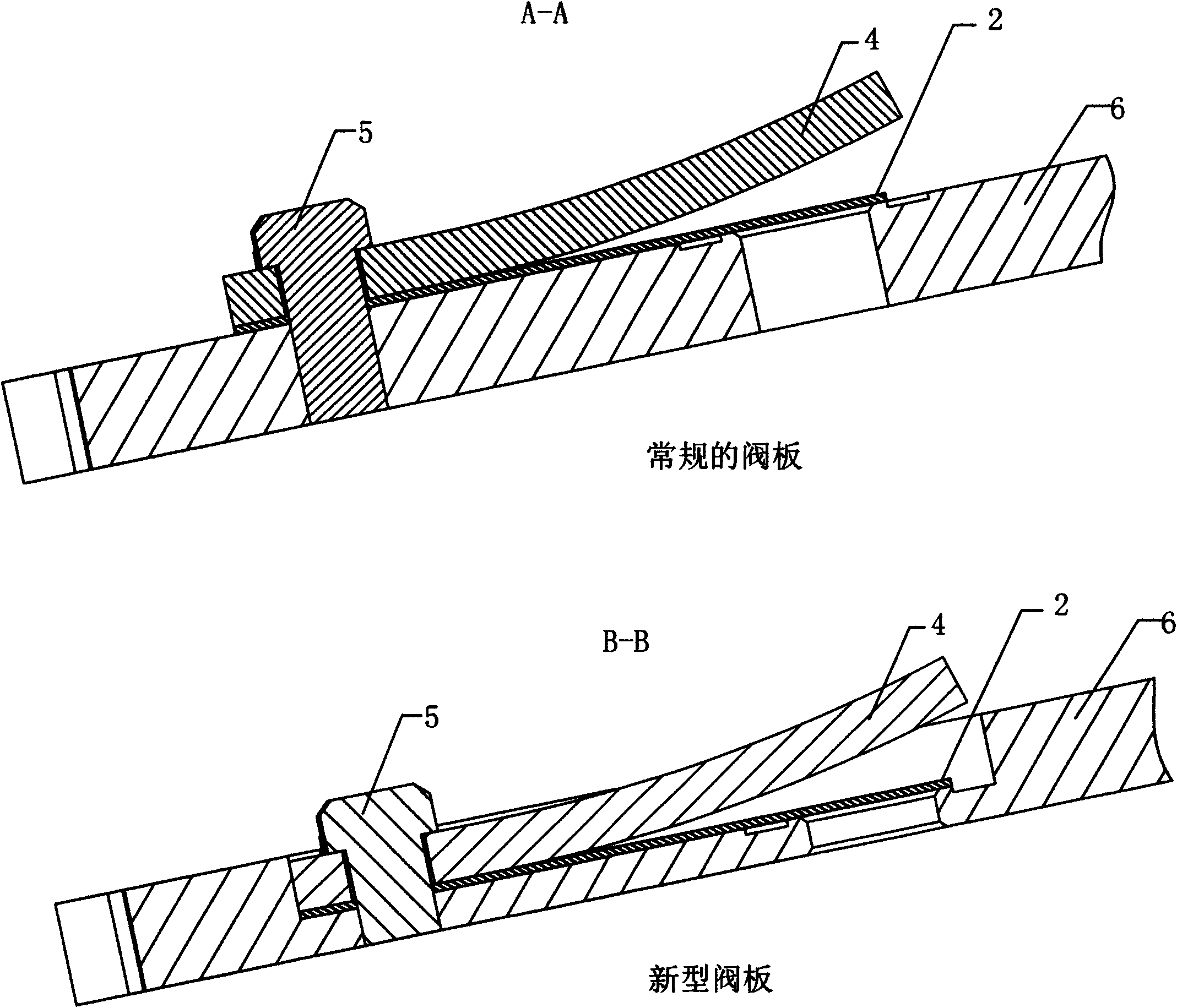

[0009] A valve plate structure for improving the efficiency of a piston compressor, which includes a valve plate assembled from an intake valve plate 1, an exhaust valve plate 2, a valve plate pin 3, a baffle plate 4, fixing bolts 5, and a valve plate body 6 Composite structure (see figure 1 and figure 2 ). The difference between the two valve plates is that the exhaust valve plate, valve plate pin, baffle plate and fixing bolts of the conventional valve plate are installed on the surface plane of the valve plate body, while the exhaust valve plate, valve plate and valve plate of the new valve plate are installed on the surface plane of the valve plate body Sheet pin, baffle plate, locating pin are installed on the processed plane of valve plate body. The main difference between these two valve plates is that the height of the vent hole of the former is 8mm, while the height of the vent hole of the latter is 2-3mm. Because the diameter of the vent hole is the same, the latt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com