Cracking evaporation type oil sand and oil sludge treatment device

A technology for sludge treatment and oil sand oil, applied in sludge treatment, water/sludge/sewage treatment, pyrolysis treatment of sludge, etc., to achieve the effect of solving uneven thermal conductivity, easy control, and direct heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

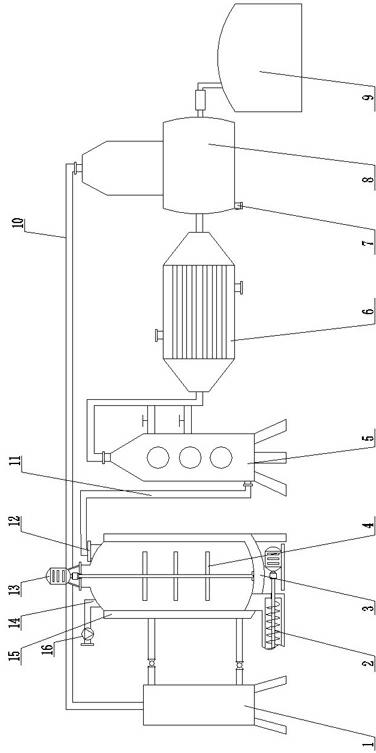

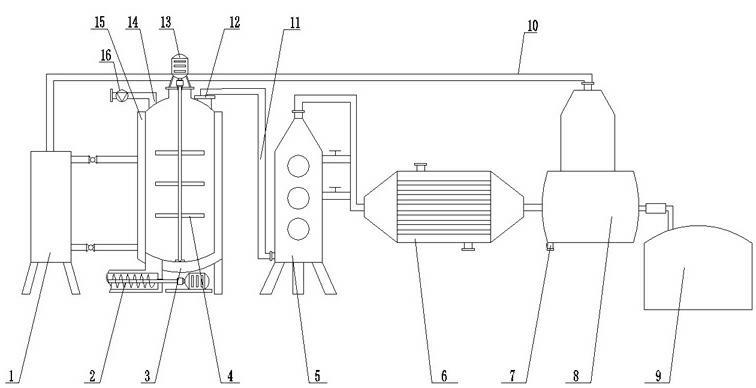

[0008] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0009] see figure 1 , the cracking and evaporative oil sand oil sludge treatment device is composed of a heating oil furnace 1, a cracking reaction tank 3, an agitator 4, a fractionation tower 5, a condenser 6, an oil-water separation tank 8 and an oil storage tank 9, etc., and the cracking evaporation tank 3 is a vertical structure, and the tank body is provided with a heat exchange interlayer 15 surrounding the inner wall of the tank. The heat transfer interlayer 15 is embedded with heat transfer oil connected to the heating oil furnace 1. The cracking evaporation tank 3 is equipped with an agitator 4, and the top of the tank The power mechanism of the agitator is equipped with a feed port 14 connected to a feed pump 16 on one side of the tank top, and an exhaust port 12 on the other side. The exhaust port 12 is connected to the vertical tank throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com