Reverse osmosis treatment system with high recovery rate

A treatment system and high recovery rate technology, applied in the direction of osmosis/dialysis water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve resin organic pollution, high operating costs, organic Pollutants and other problems, to achieve the effect of increasing ionization degree, reducing pollution, overcoming SiO2 scaling and biological fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

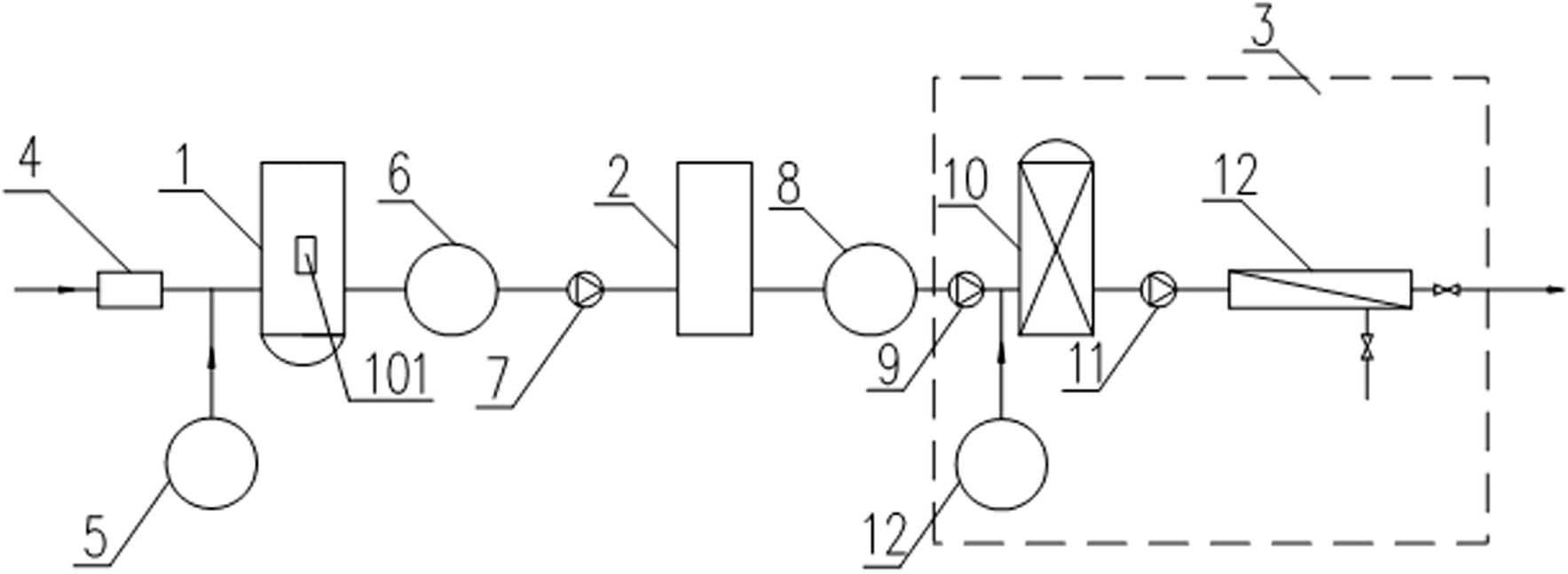

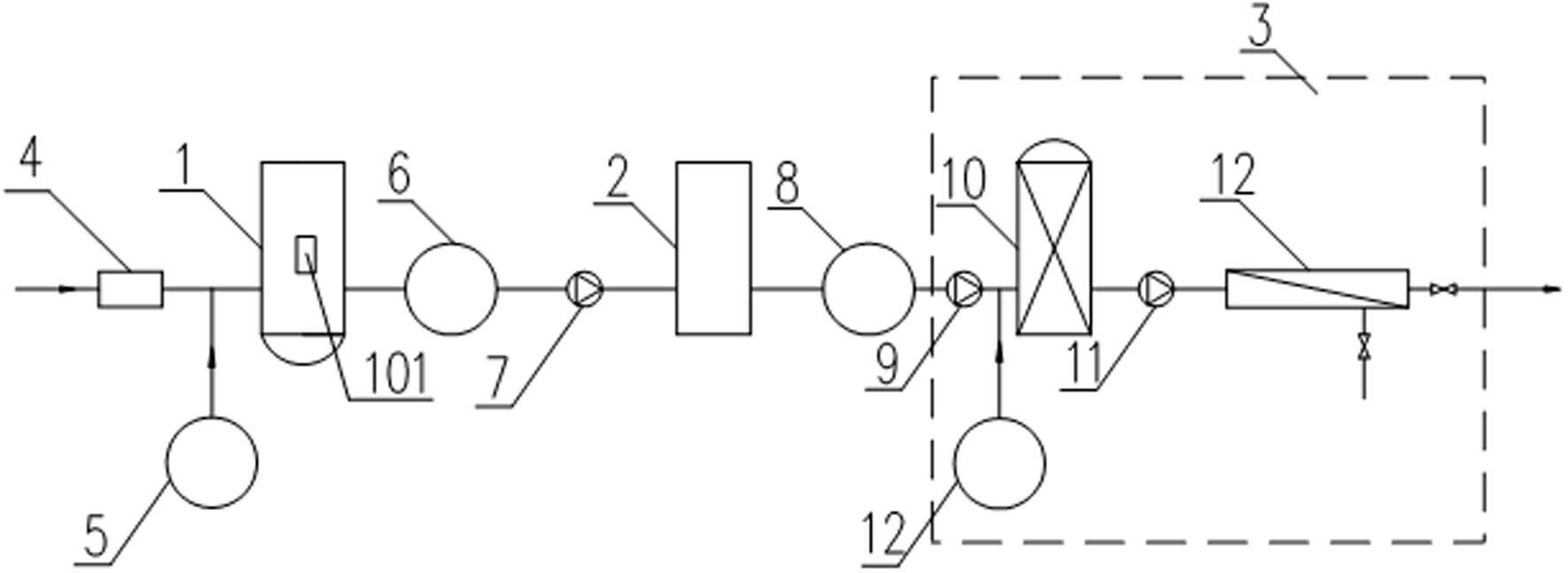

[0018] Such as figure 1 As shown, a high recovery rate reverse osmosis treatment system includes a water inlet device 4, a coagulation device 1, a filter device 2 and a reverse osmosis device 3 connected in sequence, and the water inlet device 4 is arranged on one side of the coagulation device 1, And between the water inlet device 4 and the coagulation device 1, a pH value adjustment device 5 is arranged, and the pH value adjustment device 5 communicates with the coagulation device 1, and the coagulation is adjusted by adding an aqueous alkali solution in the pH value adjustment device 5. The pH value of the water in the device 1, the coagulation device 1 is equipped with a stirring device 101, so that the sewage c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com