LED (light-emitting diode) driving and dimming method for pulse-by-pulse current adjustment by adopting frequency doubled of power frequency

A technology of LED drive and double power frequency, which is applied in light sources, electric light sources, lighting devices, etc., can solve problems such as unsatisfactory lighting effects, obvious color temperature changes, and prominent lighting safety hazards, and achieve large-scale stable dimming, overcome Color temperature drift, the effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

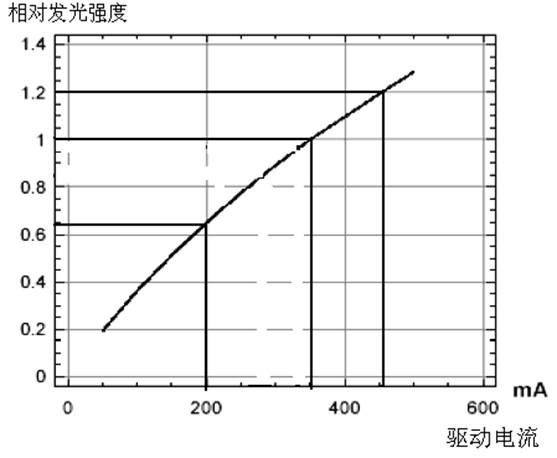

[0027] Technical requirements: 288 0.1W 3528 / 3410 SMT encapsulated LED lamp beads are used to make 18W T-tube fluorescent lamps, which can be dimmed.

[0028] First select the actual maximum working current of the LED, take 24mA, the maximum power of the lamp is 288×0.024×3.3=22.8W, and the actual maximum output power is 18W, then the duty cycle D=18÷22.8=80%

[0029] At the same time, 288 LED lamps are combined in 24 series x 12 parallel matrix, and the total constant current is 24mA x 12 = 288mA.

[0030] Figure 5 It is a schematic diagram of the T tube solution in this embodiment, using 288 0.1W 3528 / 3410 SMT packaged LED lamp beads, 24 strings × 12 parallel matrix combination, 288mA constant current, 80% duty cycle to achieve 18W output, 80% duty cycle Adjust down for continuous dimming.

Embodiment 2

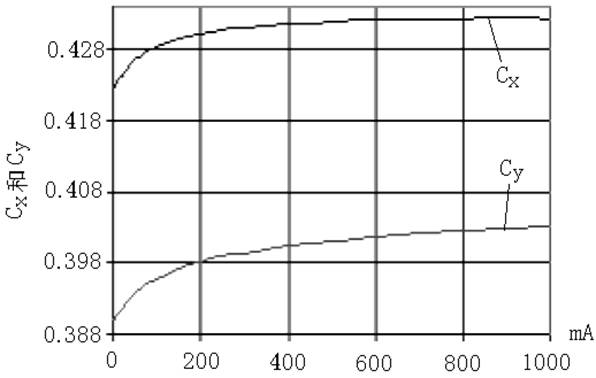

[0032] Technical requirements: Use 84 1W-3W high-power LEDs to make a 100W street light source with half-power settings.

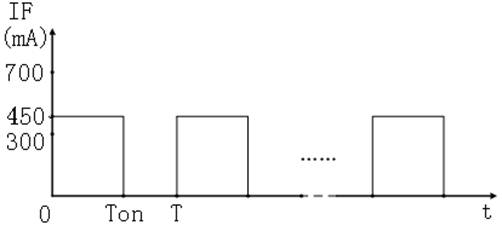

[0033] Choose a product with a single LED of 1.5W, and refer to the product parameter table to know that the working current of a single LED is 575mA, and the duty cycle D=100W÷(1.5×84)=0.8 when the full power is 100W, which corresponds to the duty cycle at half power is 0.4.

[0034] 84 LEDs adopt 42 strings × 2 parallel matrix, the total constant current is 2 × 575 mA = 1.15A, and the power frequency is doubled to 100Hz / 120Hz PWM switching frequency.

[0035] Image 6 It is a schematic diagram of the 100W street lamp solution in this embodiment, 84 pieces of 1W-3W high-power LEDs, using 42 series × 2 parallel matrix mode, power frequency double frequency 100Hz / 120Hz PWM modulation working mode, constant current 1.15A, full power 100W Select 80% for the duty cycle, and 40% for the half-power duty cycle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com