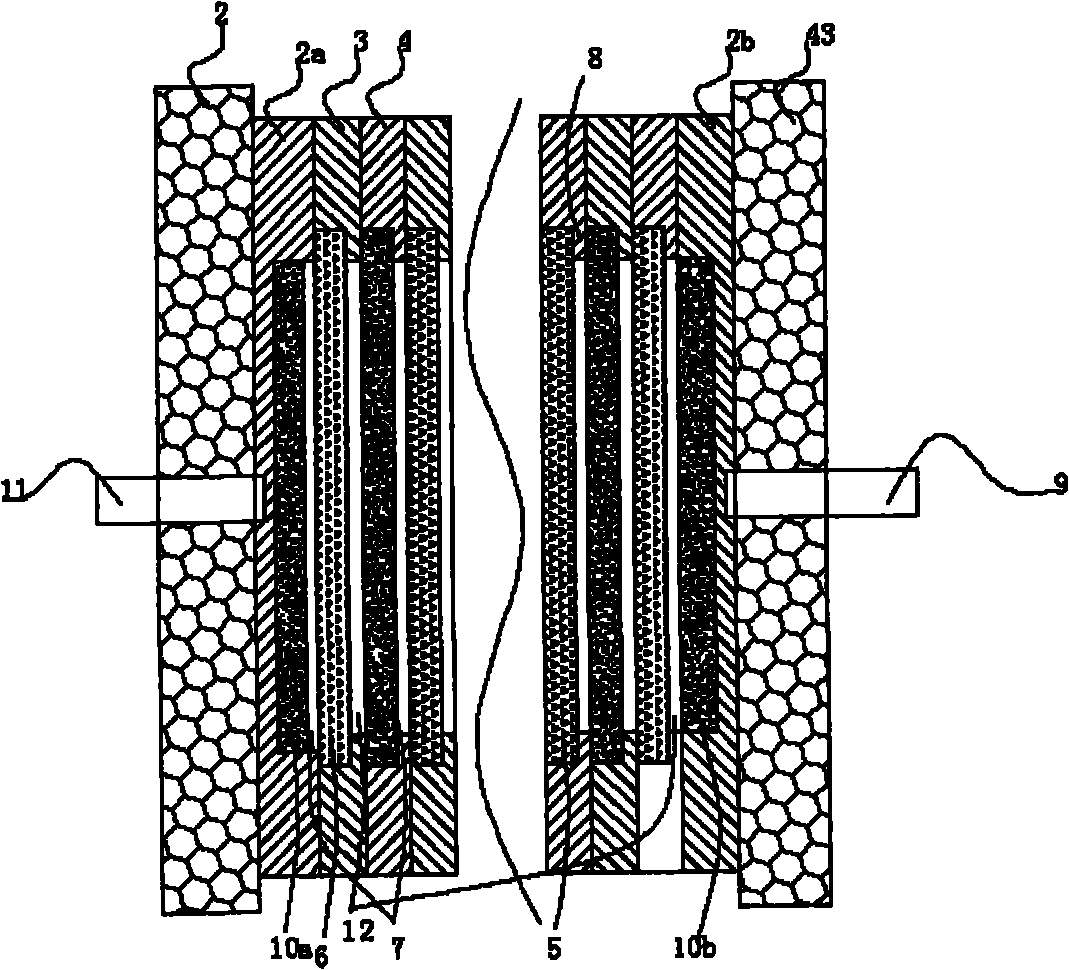

Laser welding method and device for battery component with bipolar structure

A technology of laser welding and concentrating devices, which is applied in laser welding equipment, electrical components, secondary batteries, etc., can solve problems such as imperfections, low yields, and high costs, and achieve extended service life, small welds, and improved finished products. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

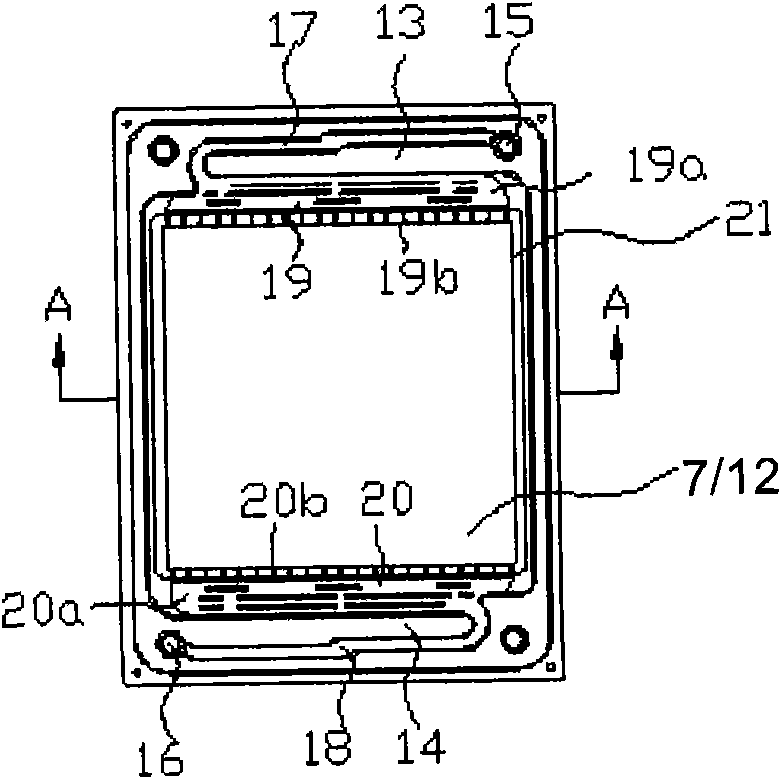

[0084] The bipolar plate to be welded (polyethylene: carbon black: graphite=4:2:4, plane size is 470mm×470mm) is placed on the upper mold 25, and then the welded frame is placed on the upper mold, with One side of the flow channel faces up, the groove 21 of the frame coincides with the four sides of the bipolar plate, and the vacuum adsorption device is turned on to fix the position of the bipolar plate and the frame to be welded; call the welding program in the control software, and set the welding parameters , including a rectangular welding path, a welding length of 470mm, a welding width of 470mm, a laser welding power of 12W, and a speed of 2.8m / min. Click the start welding button in the program to start welding. After welding, the laser welding head returns to the original position, turns off the vacuum adsorption switch, and removes the welded product.

[0085]Observing the welded parts, the color of the weld seam of the electrode plate and the frame is relatively unifo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com