Method for treating insulating oil for transformer

A transformer insulating oil and treatment method technology, applied in the direction of transformer/inductor cooling, etc., can solve the problems of long treatment time, incomplete removal of moisture and impurities, and low filtration accuracy, and achieve the effect of short treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

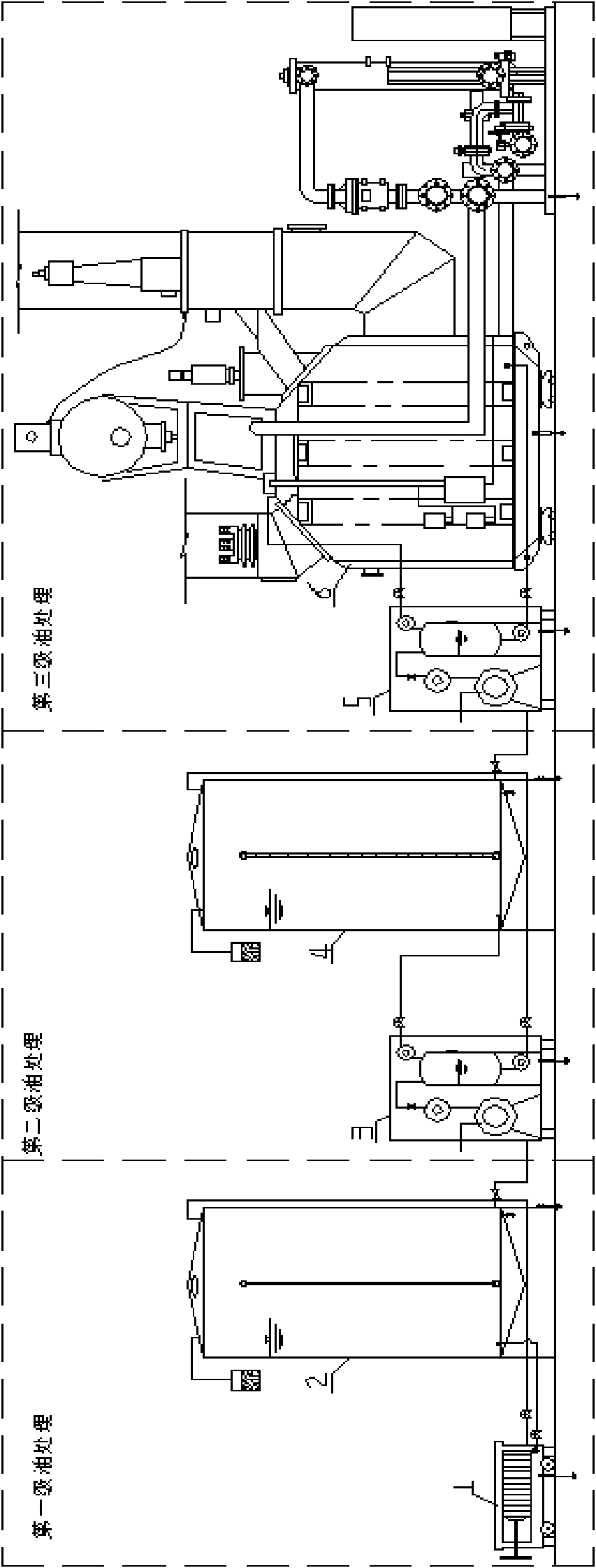

[0024] A processing method for transformer insulating oil, the method comprises the following three steps:

[0025] First-stage oil treatment: use pressure oil filter 1 to filter the particle size and impurities in the insulating oil under pressure;

[0026] Second-stage oil treatment: use the first vacuum oil filter 3 to vacuum degas and dehydrate the insulating oil treated by the first stage;

[0027] The third stage oil treatment: use the second vacuum oil filter 5 to inject the insulating oil treated by the second stage into the transformer, and perform hot oil circulation degassing and dehydration treatment to dry the transformer 6 .

[0028] like figure 1 As shown, the treatment method of 750kv power transformer insulating oil includes three steps, and its specific implementation method is: the first-stage oil treatment method: connect the oil outlet pipe of the pressure oil filter 1 to the inlet at the top of the first oil tank 2 Oil valve, the oil inlet pipe of the p...

Embodiment 2

[0034] A processing method for 850kv power transformer insulating oil, the method comprises the following three steps:

[0035] First-stage oil treatment: use pressure oil filter 1 to filter the particle size and impurities in the insulating oil under pressure;

[0036] Second-stage oil treatment: use the first vacuum oil filter 3 to vacuum degas and dehydrate the insulating oil treated by the first stage;

[0037] The third stage oil treatment: use the second vacuum oil filter 5 to inject the insulating oil treated by the second stage into the transformer, and perform hot oil circulation degassing and dehydration treatment to dry the transformer 6 .

[0038] Same as Example 1, press figure 1 Connect the equipment as shown, so that the main control indicators: oil insulation electric strength, moisture content, gas content and dielectric loss, etc. meet the standard value of the 850kv transformer voltage level. The implementation effect of this embodiment is the same as that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com